Industrial 3D printer manufacturerDesktop Metal曾在2023年宣布了一项额外的5000万美元削减成本计划,该计划将根据近期收入的产生优先考虑运营和投资,并建立该公司以实现其长期财务目标。

四个设施将关闭,桌面金属将使其劳动力减少约15%。

削减成本策略的一个关键组成部分是一致的努力,将整个美国和加拿大的众多地点简化和集中到德克萨斯州,宾夕法尼亚州,马萨诸塞州和中西部的四个枢纽。削减成本的策略还需要减少15%的劳动力。该计划以及始于2022年6月的成本优化和战略整合计划的结合,预计将在2023年每年储蓄1亿美元。桌面金属将提供有关这项工作进展的其他信息。

“这些降低成本将有助于我们提高利润率并降低成本以加速我们的盈利道路。添加剂制造业继续在宏伟的宏观经济环境中继续成熟和扩展,” Desktop Metal的创始人兼首席执行官Ric Fulop说。

桌面金属的工业投资组合

之前,桌面金属收到了900万美元从匿名汽车客户订购。尽管桌面金属尚未命名其客户,但它已将其定义为质量生产动力总成零件的“主要德国汽车制造商”。实际上,消费者的新粘合剂喷气系统将在一年内第二次使用,以帮助生产数字化汽车组件。

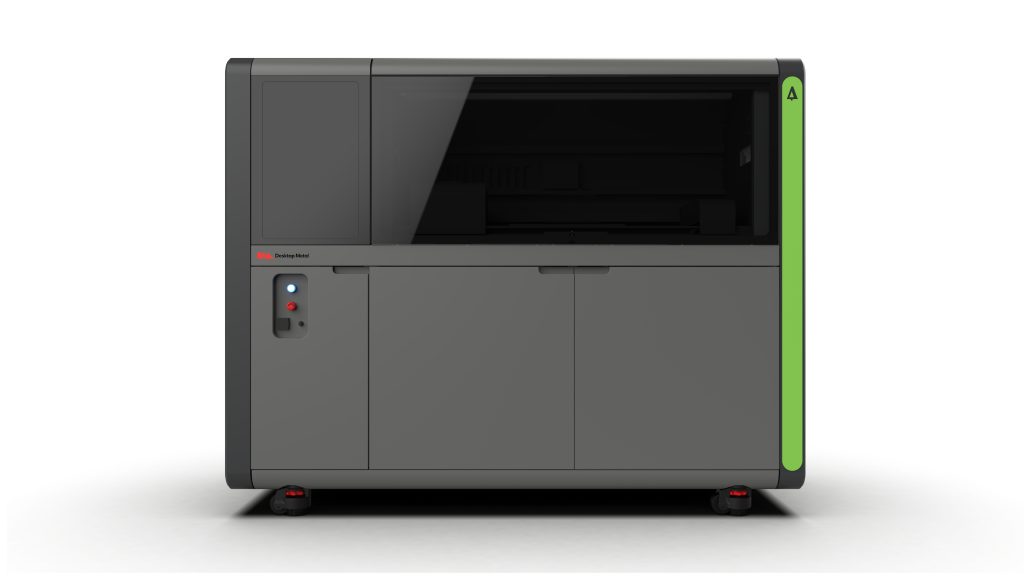

此外,该公司引入了基于木材的粘合剂喷射版of itsShop System。公司的Shop System Forust Edition, which is based on a technology created by itsForustsubsidiary, is capable of converting repurposed sawdust into functional, end-use wooden parts. Though it was initially announced last year, Desktop Metal has since streamlined the workflow and is being marketed as a turnkey system with prospective architecture, design, consumer, and automotive applications.

“Our talent is the critical success factor that helps us drive the industry forward. These actions reinforce our highest priorities and create a flatter, more agile organization. I value the contributions of everyone who has served and continues to serve Desktop Metal. We are committed to managing this transition with care and respect,” added Fulop.

在其他地方,桌面金属了FreeFoam, a novel3D printable photopolymer resinfamily with heat-activated foaming agents. FreeFoam, developed by Texas-based materials specialistAdaptive3D, a Desktop Metal subsidiary acquired in 2021, can be programmed to enlarge anywhere between 2 and 7 times the original printed size without the need for any tooling. Consequently, tunable and durable closed-cell foam parts are produced, that are expected to be widely used in industries like automotive, furniture, sporting goods, footwear, and healthcare.

AM companies that facilitated cost-reduction plans

以前,石油和天然气巨头Shell与Poly Products, a fiberglass reinforcement specialist, to reverse engineer and 3D print an obsolete part for one of its offshore structures. Shell Nigeria used additive manufacturing to create a seal cover for a mooring buoy in one of its offshore locations after the part became unavailable on the market, posing significant cost and lead time issues. Collaborating with Poly Products, the team was able to decrease the part’s lead time from 16 weeks to just two, resulting in a 90 percentcost savings。

Elsewhere, by redesigning the door hinge of a luxury sports car, theFraunhofer Institute for Additive Production Technologies(IAPT)说明了3D打印如何改善制造成本和技术性能。为了最大化体重和cost savings, IAPT’s engineers optimized every aspect of the geometry of the door hinge to the build orientation and process variables during the part redesign project. Finally, the project aimed to shed light on the less obvious factors that affect the costs of 3D printed parts, in addition to the geometry of the parts themselves.

什么does thefuture of 3D printing在接下来的十年中?

什么engineering challenges未来十年,是否需要在增材制造业中解决?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the3D打印行业通讯or follow us on推特, or like our page onFacebook。

当您在这里时,为什么不订阅我们Youtube频道吗?特点ring discussion, debriefs, video shorts, and webinar replays.

您是否正在寻找增材制造业的工作?访问3D打印作业在行业中选择一系列角色。

特点re image shows a render of Desktop Metal’s Shop System Forust Edition. Image via Desktop Metal.