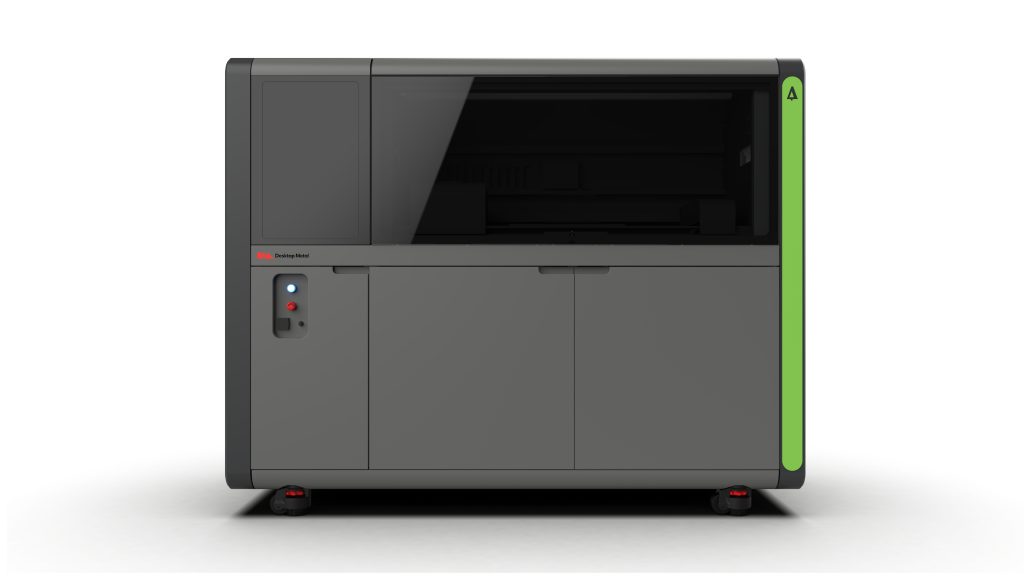

Industrial 3D printer manufacturerDesktop Metalhas announced the launch of a wood-based binder jetting version of itsShop System。

基于技术的开发Forust子公司,公司的Shop System Forust Edition, is capable of turning upcycled sawdust into functional, end-use wooden parts. Though it was first unveiled last year, Desktop Metal has since refined the process, and it’s now being marketed in the form of turnkey systems, with potential architecture, design, consumer and automotive applications.

桌面金属的创始人兼首席执行官里克·富洛普(Ric Fulop)说:“我们的新商店系统Forust版本使创建定制和复杂的木材设计具有3D打印机的需求,规避供应链挑战并提供全新的设计可能性。”“我们认为,这个概念能够随着时间的推移提供有意义的可持续性影响并扩展到其他粉末状废料。”

Disrupting woodworking with Forust

去年,Forust Technology旨在使木材3D印刷负担得起,可靠和可持续性。它这样做的一种方法是将木材制造业和造纸工业的高扫描废物作为原料。桌面金属子公司说,这将是驱动净零,“添加剂重新布局”并建立更可持续的未来的关键。

At first, the technology was launched solely in the form of an online store, through which clients could order custom parts. However, having optimized the process with beta users, Desktop Metal is now bringing it to market via a fully-fledged machine, shipped with a comprehensive post-processing guide to help adopters create the best possible circular wood-based builds.

“One of the great things about binder jet 3D printing technology is it can transform virtually any powder material into functional, end-use parts,” added Fulop. “Beginning with an ample supply of sawdust byproduct from the traditional wood milling industry, we are using our technology to build cradle-to-cradle manufacturing for wood.”

Taking Forust technology to market

While based on Desktop Metal’s Shop System, its first commercially-available Forust machine has been modified to safely process the unfinished sawdust byproduct of the wood milling industry. Like its predecessor, the Forust Edition works by using an industrial printhead to selectively deposit binder onto a powder bed, only it does so much more quickly, at speeds of up to 1,600 cc/hr rather than 800 cc/hr.

有趣的是,当与桌面金属一起使用时Fabricate MFG构建准备软件,该机器允许用户不用谷物图案进行打印,也可以从五个预设中进行选择。实际上,这意味着采用者现在将能够用逼真的图案制造定制的家居装饰物,从而准确地复制灰烬和桃花心木等天然木材。

浸润后,也可以像传统的木制品一样磨碎,染色,抛光,染色,涂层,涂覆和修补,并且据说这些零件具有相似的强度,这意味着它们可以被拧紧或钉子。

在发布会上,Forust Edition带有Forust Wood Powder的船,将原始木屑和未完成的木屑混合在一起,但桌面金属也正在制定指南,以允许用户打印自己的材料。将来,该公司期望其机器在服务局,建筑师和设计师中会很受欢迎,因为它可以生产高质量的自定义木材产品,这些产品与功能相结合。

Technical specifications and pricing

Below are the technical specifications for the Desktop Metal Forust Shop System. Desktop Metal has announced that the 3D printer is now “available to purchase internationally.” Those interested in buying the machine canrequest a quotefrom the company directly, or take a closer look when it debuts atFormnext从2022年11月15日至18日。

| Technology | Binder Jetting |

| Build Box | 350 x 220 x 200 mm |

| 打印速度 | Up to 1,600 cc/hr |

| 材料 | Forust Wood Powder |

| 软件e | Fabricate MFG |

| Anicillaries | Forust Powder Station |

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the3D打印行业通讯or follow us onTwitteror liking our page onFacebook。

当您在这里时,为什么不订阅我们Youtubechannel? featuring discussion, debriefs, video shorts and webinar replays.

您是否正在寻找添加剂制造业的工作?访问3D打印作业在行业中选择一系列角色。

Featured image shows a render of Desktop Metal’s Shop System Forust Edition. Image via Business Wire, Desktop Metal.