医疗设备供应商rms company添加了一个3D系统DMP Flex 350 Dual 3D打印机在其3D打印综合体中,有30多个机器的印刷农场。

Through its facility, rms offers medical OEMs complete ‘Powder to Package’ services, which allow them to go from a digital file to a sterilized, packaged final product. By expanding its capabilities with a DMP Flex 350, the firm anticipates being able to not only produce new types of implants but “accelerate throughput” across the board.

“rms company decided to invest in a DMP Flex 350 Dual [because] it is engineered in a way that allows us to produce the high precision, high-quality products we expect from our current installation of DMP systems without changing the processing parameters we validated when we initially developed our AM capabilities,” explains Ryan Kircher, a senior additive manufacturing engineer at rms company. “This [also] allows us to explore not only new products but reduce production times and costs.”

3D系统’ DMP Flex 350 systems

Unveiled back in 2018, 3D Systems’ DMP Flex 350 machines are designed to enable the high-throughput, low-cost, and repeatable production of high-quality parts from challenging alloys. Compared to their predecessor, the ProX DMP 320, the 3D printers feature a new integrated Powder Management Unit (PMU), to ensure consistent part quality, and boast a 15% overall productivity boost.

DMP Flex 350的单激光器和双激光版本也具有独特的真空室概念,可驱动用户的氩气消耗,并使其达到高氧纯度(<25 ppm)。结果,据说系统可以最大化可以重复使用的粉末量,并允许产生具有高化学纯度的极强零件。

When resulting parts undergo hot isostatic pressing, they’re even said to be of comparable quality to forged parts, something that could lend them aerospace use cases. That said, 3D Systems doesn’t just market the machine as a tool for producing end-use aerospace parts. Rather, the firm says its system can address user needs ranging from R&D and application development to serial production, in any area where custom lightweight metal parts are needed.

rms’ Powder to Package offering

rms公司引以为荣的是larg之一est contract manufacturers of high-quality, tight-tolerance medical devices in the world. Through its Powder to Package offering, the firm produces precision machined components and assemblies at prototype, pre-production, and post-launch volumes, for builds such as pacemakers and endoscopy devices.

Over the last four years, 3D Systems has helped rms company expand the metal 3D printing behind its services, from just a single system to more than 30. While this has already allowed the business to establish itself a strong reputation as a manufacturer of high-quality titanium implants, adopting the DMP Flex 350 is expected to enable an increase of up to 50% in its small implant throughput.

该公司的工程师还认为,这些生产力的提高将在生产大型关节和肢体植入物的生产方面开辟新的机会,这些植入物以前对单个激光系统在经济上具有挑战性。此外,该公司表示,意识到安装DMP Flex 350的好处并不需要任何参数调整,因此扩大其容量是一个无缝的过程。

RMS Company增材制造部运营总监Troy Olson补充说:“这些机器上的正常运行时间对于我们维持客户的承诺至关重要。”“我们的打印机以24/7的生产节奏运行,这几乎没有停机的空间。在我们的验证过程中,DMP Flex 350双重二元在机械性能或尺寸精度上没有可测量的差异。我们很高兴将这种新功能添加到我们现有的印刷操作中。”

“As we continue to scale our additive manufacturing business, the 3D Systems DMP Flex 350 Dual will be at the forefront of our growth strategy.”

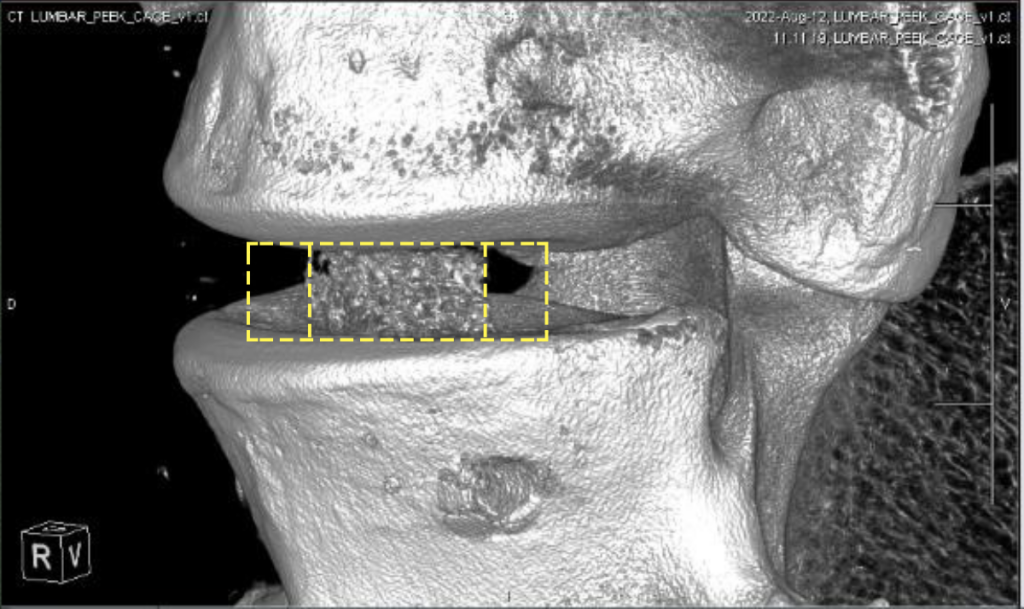

Additive manufacturing continues to gain popularity among medical OEMs as a means of producing customized surgical implants. Late last year,Bond3D和Invibio生物材料解决方案unveiled a technology for the3D printing of next-generation spinal cages, which enables them to be configured in a way that accelerates patient recovery.

Likewise, 3D printed maxillofacial implants by the likes ofCerhumhave come on leaps and bounds in recent years. Not long after itsMybone医疗设备获得了批准为了在整个欧洲的患者中使用,Cerhum的技术也被部署在Claudius Regaud Institute和图卢兹大学医院, as part of an operation that saw a cancer用3D生物打印鼻子治疗的患者.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the3D Printing Industry newsletteror follow us on推特或喜欢我们的页面Facebook.

While you’re here, why not subscribe to ourYoutube渠道?包括讨论,汇报,视频短裤和网络研讨会重播。

Are you looking for a job in the additive manufacturing industry? Visit3D Printing Jobs在行业中选择一系列角色。

Featured image shows a build plate full of 3D printed spinal implants. Image via 3D Systems.