从核能开始,这是一系列访谈中的第一篇文章3D printing and renewable energy随着研究人员,企业和世界领导人承受着不断增加的压力,以改善其可持续能源战略。

Oak Ridge National Laboratory(ORNL) is the largest energy research lab in the U.S. “Clearly, further electrification of the manufacturing sector through 3D printing is the near-term opportunity for decarbonization,” say Professor Xin Sun, Associate Laboratory Director for Energy Science, and Kathy McCarthy, Associate Laboratory Director for Fusion and Fission at ORNL.

我与橡树岭专家谈到了3D印刷在ORNL目前正在进行的众多核能项目中的应用,以及添加剂制造将如何改变核能。

根据全球能源评论2021在2020年的共同侵犯期间,可再生能源使用量增加了3%,而对所有其他领域的需求下降。撇开大流行,绿色能源有continued to grow近年来,它在能源市场中所占的份额,预计将是到2030年的价值高达21.72亿美元。

来自世界各地的国家签署了格拉斯哥气候条约在COP26上,面临呼吁对降低煤粉和化石燃料的使用,以遏制其排放,这是对可再生能源技术的投资,目前每年3000亿美元,看起来将在未来十年迅速增加。

3D printing’s role in nuclear energy

核能是一种“清洁”能源产生的一种形式,它正在受到越来越多的关注,作为燃烧化石燃料的替代品。尽管核电的优点包括提供无碳电力,小土地足迹,高功率输出和可靠性,但它也有一些缺点。

例如,铀是最广泛用于核裂变的燃料,尽管它丰富了,但从技术上讲是一种不可再生能源,而高前期成本以及与核废料和植物故障有关的安全问题可能可能是灾难性的。但是,增材制造是starting to be deployed in this area减少许多关注点并领导指控是ORNL。

“ 3D打印核部件已经对当今的核部门产生了影响,” Sun和McCarthy告诉我。ORNL目前正在领导Transformational Challenge Reactor(TCR)由US Department of Energy(doe),目的是建立核反应堆核心使用其他技术以及其他技术。

他们说:“简化制造和降低成本的同时维持安全运营是核能未来的关键。”“高级制造可以通过减少研发时间来降低核能的成本new nuclear designs,能够更快地部署新技术,支持快速设计开发和integrating essential technologies like sensors和人工智能(AI)成组件,以确保核设施的安全运行。”

启用以前不可能的设计

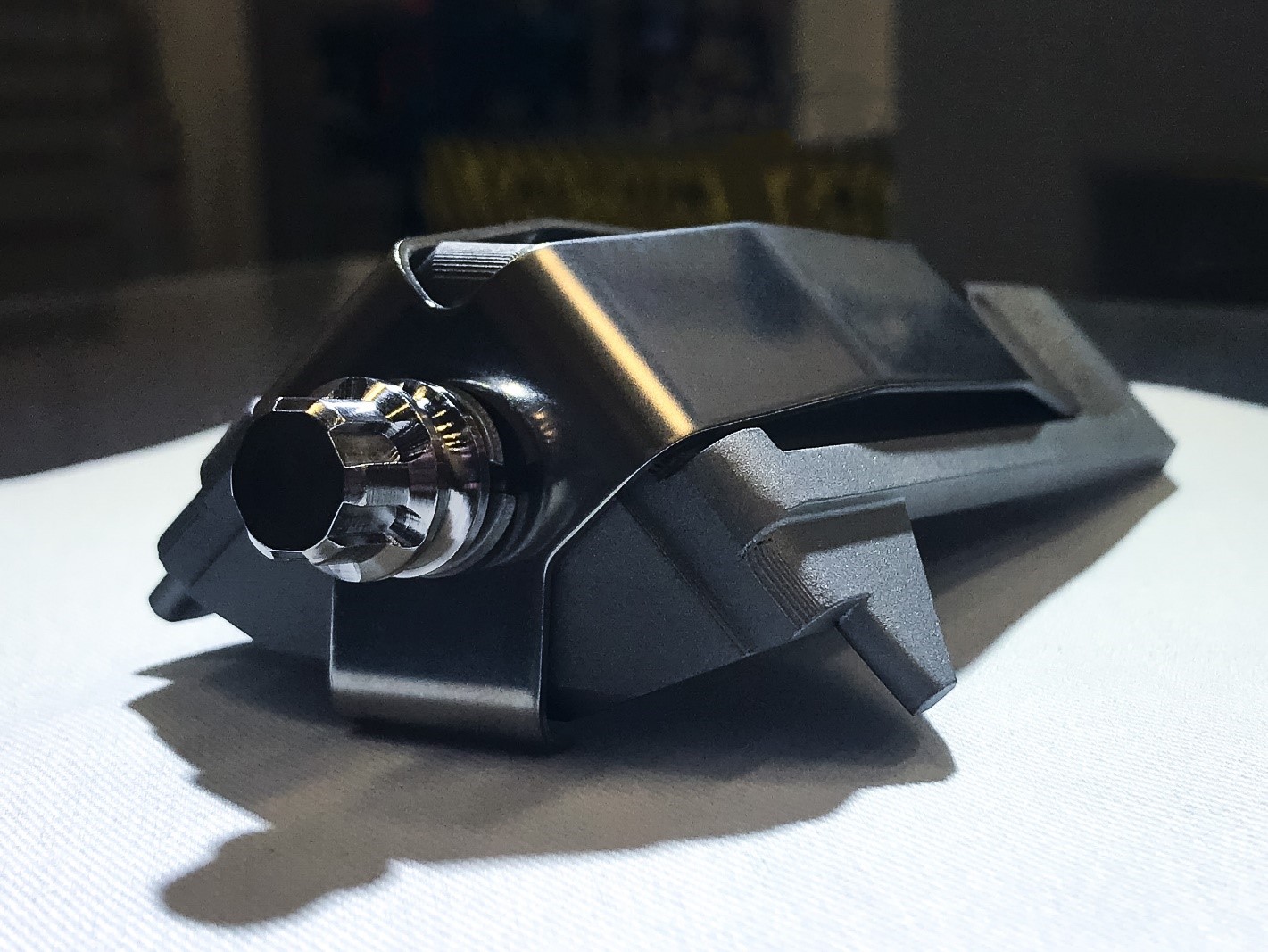

去年,核反应堆成分使用ORNL开发为TCR程序的一部分own 3D printing technologyfor nuclear supplierframatome安装在田纳西河谷管理局’s棕色渡轮核电站in Alabama.

“3D printing also allows us to manufacture designs that aren’t possible with traditional techniques, opening the door to component geometries not otherwise achievable through traditional manufacturing, leading to higher efficiency along with cost savings,” added Sun and McCarthy.

Looking ahead to other types of nuclear components ORNL’s 3D printing method could be suited to, the professors predict an increase in small modular reactor designs alongside a new set of geometries only made possible by additive manufacturing. According to Sun and McCarthy, these components will become integral to the digital infrastructures of current nuclear facilities.

“Smart components with sensors that integrate with data management systems are appealing both for routine nuclear operations and for the development of advanced nuclear systems,” they add. “An example of an application for these sensors is online monitoring – looking for signs of component degradation enabling repair prior to failure.

“这些类型的组件也可以在核认证过程中发挥重要作用。”

核中AM的采用日益增长

3D打印核部件的认证和资格是该技术在该领域更广泛采用的关键要素。当监管机构正在努力调整时,来自核监管委员会Sun和McCarthy说,没有想到现代制造工艺实施的制造范式转变。

“ ORNL一直处于这项研究的最前沿,通过AI和机器学习开发了数字制造技术,可以帮助支持“出生合格”组件的制造。如今,ORNL生产的每个组件都有独特的数字护照,可捕获制造过程的整个历史。”

ORNL打印组件的方法最近获得许可by theUltra Safe Nuclear Corporation(USNC) using refractory methods such as silicon carbide, marking a significant step forward for the technology’s wider adoption in nuclear.

随着工业部门每年消耗美国总能源消耗的33%,该行业是该国脱碳工作的关键组成部分。因此,在短期内,核3D打印的最大机会是对制造业和脱碳化的进一步电气化,Sun和McCarthy说。

“In the future, 3D printing can enable novel design through part consolidation and process intensification, leading to enhanced efficiency and reduced cost of future energy systems and carbon capture systems,” they add.

确保subscribe to our newsletter而且,不要错过该系列的下一部分,我们将研究太阳能在太阳能空间内的3D打印应用程序上的升起。

Looking for a career in additive manufacturing? Visit3D打印作业在行业中选择一系列角色。You can also stay connected by following us onTwitter并喜欢我们Facebook。

订阅我们YouTube channelfor the latest 3D printing video shorts, reviews and webinar replays.

特色图片显示一个ORNL 3D printed channel fasteners for Framatome’s boiling water reactor fuel assembly. Photo via Framatome.