The global 3D printing market grew by 21 percent in 2020 compared to 2019 to an estimated value of $12.6 billion despite the effects of the Covid-19 pandemic, according to on-demand manufacturing platform3D Hubs’2021 3D打印趋势报告。

该年度报告表明,由于Covid-19的结果有限,由于COVID-19的导致传统制造技术的访问有限,这有助于加速去年的采用添加剂制造,而与2019年相比,有65%的工程业务增加了其3D打印的使用。

展望未来,该报告预测,在未来五年内,3D打印市场的规模将两倍多,估计价值为2026年的372亿美元。

3D打印趋势报告

最新版本的3D枢纽的3D打印趋势报告旨在回顾添加剂制造的整体市场增长,包括Covid-19的影响,以及揭示了该技术的需求最高以及它仍然面临的采用障碍。

The report is comprised of data from three main sources, including a survey conducted by 3D Hubs with 1,504 engineering businesses. The report also collected data via a systematic review of news reported by the media, and identified market trends through comparing various market analyst reports such asWohlers Associates’ recently released2021 State of 3D Printing report。

Last year’s 3D Printing Trends reportalso predicted long-term growth for the additive manufacturing sector, bolstered in part by the raising ofmore than $1.1 billion by 3D printing startupsin 2019.

尽管Covid-19

去年年初,随着冠状病毒在整个大陆越来越大,制造地面停止了,关闭了工厂并停止了许多行业的生产。因此,gaps began opening in supply chainswhere demand outstripped supply.

根据3D枢纽的报告,3D打印在快速的角色中获得了“主流风险”producing Personal Protective Equipment(PPE)和组件medical devices such as ventilators。随着全球供应链破坏,企业更难从海外采购零件,更多的本地和分布式制造设置(例如3D打印)是turned to for both prototyping and end-use parts.

尽管3D印刷行业对过去一年的挑战尚未完全弹性,但该报告指出,该技术“然而,未来三年仍将继续同比增长17%。”

The survey carried out by 3D Hubs reveals that, as a result of the pandemic, 33 percent of engineering businesses increased their 3D printing usage, while half of the 1,504 respondents maintained their usage. The firm attributes this finding to engineering firms having more downtime than usual, giving their teams the chance to focus more time on research and development, testing and prototyping.

The report suggests firms also realised lead time benefits of 3D printing over machined and injection molded parts for some applications.

Shift from prototyping to production

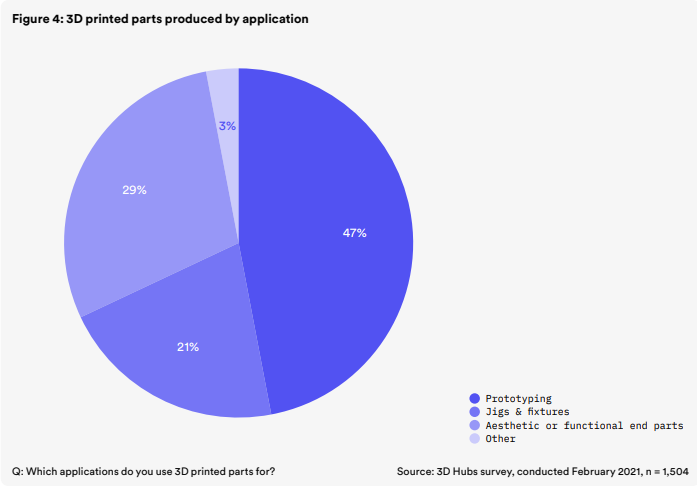

虽然3D打印目前主要用于原型制作,但该报告指出,工程公司正在看到该技术“越来越多地用于最终用途零件”。根据3D枢纽的调查,有47%的工程业务部署了3D打印来进行原型制作,而29%的工程业务将技术用于美学或功能性最终用途零件。

In fact, more than half of engineering businesses revealed they had increase their use of 3D printing to produce functional end-use parts during 2020, while 30 percent reported their use of 3D printing for end-use parts remained the same in 2020 compared to 2019.

According to the report, the industries that reported the largest increase in their use of the technology for end-use parts included biotechnology, transportation, and automotive. As the report points out, “biotechnology and automotive are industries that especially benefit from the设计复杂性3D打印优惠” while the transportation sector tends to deploy the technology toproduce spare, custom partsthat are otherwise hard or expensive to source.

Looking ahead to 2021 and beyond

The report predicts 3D printing to “continue on its path of growth” in 2021, with 73 percent of engineering businesses estimating they will produce or source more 3D printed parts this year compared to 2020.

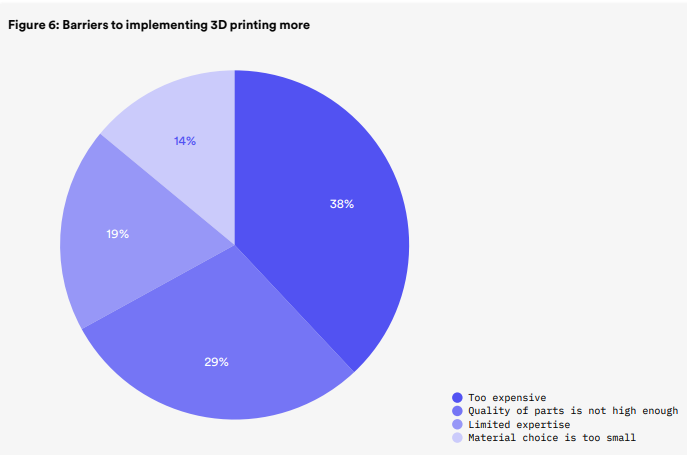

然而,成本,质量,部分专业知识有限,一个d material choice limitations are all factors holding back the adoption of additive manufacturing, according to respondents of 3D Hubs’ survey. The report points to the higher price point per part for high volumes of 3D printing compared to other manufacturing technologies, as well as the higher cost of metal 3D printing technologies such as selective laser melting (SLM) and direct metal laser sintering (DMLS).

Counteracting these perceived barriers, according to the report, is the greater design flexibility offered by 3D printing which can lead to improved strength-to-weight ratios and more efficient parts. In addition, the report sees the development of new materials and techniques within metal 3D printing as a means to lower the cost of the technology.

Rounding off its report, 3D Hubs asked more than 1,500 3D printing users in its community to predict how they foresee the industry evolving throughout 2021. The general consensus among respondents is that there will be a continued shift towards more end-use parts and the cost of the technology will gradually become cheaper in order to open the technology up to more applications.

Hybrid manufacturing还预计今年将“取得更大的进步”,“物质自由”,工作流软件以及3D打印中的表面饰面和合金的改进。

The fullAdditive Manufacturing Trends Report 2021from 3D Hubs can be read in full here.

Subscribe to the3D打印行业通讯for the latest news in additive manufacturing. You can also stay connected by following us onTwitter并喜欢我们Facebook。

Looking for a career in additive manufacturing? Visit3D打印作业在行业中选择一系列角色。

Featured image showsa 3D printed part produced by 3D Hubs on HP’s Multi Jet Fusion. Image via 3D Hubs.