3D printing material developer and service providerCRP Technologyhas developed end-use parts for several exotic limited edition sports cars, it has been revealed.

Designed as part of the ‘Iconic Brands’ initiative, these retaining duct, pipe, wiring system, and aero components are said to be lighter, more durable, and yield greater downforce, in a way that makes them better capable of withstanding high-speed applications, and enables them to make supercars quicker on-track.

虽然该公司尚未透露其背后客户的身份,但它说3D打印了零件Windform RShas helped users unlock “outstanding endurance and aerodynamic performance.”

CRP Technology的赛车运动血统

CRP技术于1996年建立在意大利汽车谷中心,主要被称为Windform材料的开发商。但是,鲜为人知的是该公司是由CRP Meccanica,Roberto Cevolini&C的继任者,该公司最初致力于创建F1零件。

得益于在研发上进行了将近三十年的投资,以及这种继承的汽车专业知识,CRP Technology已经能够开发出几种能够承受恶劣环境条件的3D打印材料。

其中的最新示例包括Windform XT 2.0用于高速烧结,火焰刺激器Windform FR2和Windform RS,一种充满碳纤维的材料,可产生重型零件。过去,公司的材料已被用来创建所有内容加固的3D打印无人机到Windform-based satellites,尽管它继续满足各种行业的用户需求,但事实证明,他们特别适合汽车。

In fact, CRP Technology says its engineering expertise and motorsport knowledge allow it to deliver functional components that are more reliable, lightweight and liquid resistant than printed competitors. As a result, the company’s premises in the US, Italy and Dubai are now said to create parts for multiple automotive leaders, via its suite of manufacturing services.

比铝制零件强?

为了庆祝Windform RS发射一周年,CRP Technology为其标志性品牌项目提供了见解。具体而言,该公司表示,它已经“成熟了许多重要的参与”,与备受瞩目的制造商一起为汽车生产了50,000个复杂零件,仅去年一年,2020年就增加了10%。

Modern vehicles are operated by various automated controls that necessitate the coexistence of electronics, fluids and energy cables, capable of operating in tight spaces. As such, CRP Technology considers Windform RS to be ideal for meeting high-end automotive needs, especially as it can be used to create standalone retaining systems, housing-to-power cables reaching an 800W voltage, and aero parts that can easily be quality-assessed.

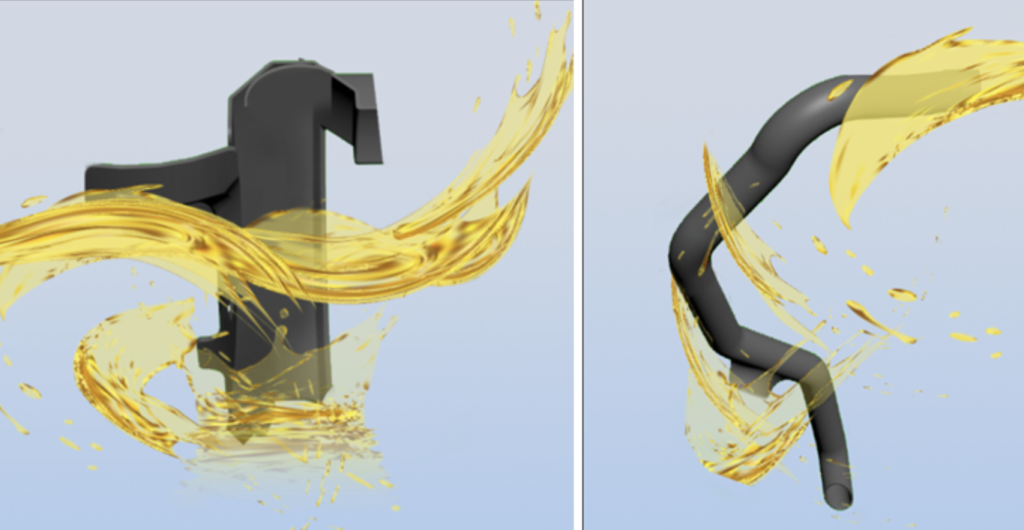

过去一年,该公司曾与partners to 3D print several end-use components from the material, ranging from oil circuit supply and intake piping, the latter of which outperformed an aluminum version in temperature, fluid environment and vibration testing that took place inside a crankcase.

在另一个研发项目中,CRP技术还有助于开发一种能够持续耐力赛等24小时Le Mans的管道系统。由于Windform RS的热阻力品质,该公司表示,该部分现在已经以几个月的连续使用速度以高达340 km/h的速度持续使用,而不会遭受变形或损坏。

通过3D打印来应对航空阻力

When it comes to the adjustable winglets fitted to F1-esque supercar drag reduction systems that open to reduce drag and improve their speed and stability, reliability is key. On the road, such louvers (as well as splitters), must regularly perform at speed, and using Windform RS, CRP Technology has managed to create these parts, which once fitted, ensure a high aerodynamic load.

在其他型号上,该公司还将其材料部署到3D打印涡流发生器,外部身体部位会导致汽车上的气流变得更加动荡,并创建了“主动空气动力学”元素。

当适合下一代超级跑车时,它们会自动或半自动触发,以提高车辆性能或燃油消耗。CRP Technology利用Windform RS,现已与一个未命名的合作伙伴合作,以创建更强大的空气增强DRS Winglets,能够承受由粗糙的沥青或热变化引起的压力。

尽管通常在极度苛刻和昂贵的制造过程中完全由碳制成,但该公司现在已经3D使用其材料将它们打印出来。它说,这是因为Windform RS具有“对温度偏移的特殊抵抗力”,并且可以使其“履行其任务”,无论其遭受多少热空气。

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the3D打印行业通讯or follow us onTwitteror liking our page onFacebook。

当您在这里时,为什么不订阅我们Youtubechannel? featuring discussion, debriefs, video shorts and webinar replays.

您是否正在寻找添加剂制造业的工作?访问3D打印作业在行业中选择一系列角色。

Featured image shows a silhouette of a supercar. Image via CRP Technology.