Nominations for the2021 3D Printing Industry Awardsare now open, have your say who is leading the industry now.

3D printer manufacturerStratasyshas furthered its commitment to achieving circular economy processes, climate action and social change within the 3D printing sector by establishing its Stratasys Sustainability function.

Having appointed Rosa Coblens as its Vice President of Sustainability, the company is seeking to pursue its sustainability agenda based on theUnited Nations’ (UN) Sustainable Development Goals(SDGs). As part of this mission, the firm has joined theAdditive Manufacturer Green Trade Association(AMGTA) as a Founding Member, of which Coblens now serves on the Board of Directors.

According to Stratasys CEO Yoav Zeif, now is the time for the 3D printing sector to embrace “mindful manufacturing”.

“The new global economy requires companies to adapt and overcome unexpected challenges, while maintaining a commitment to environmental stewardship,” he said. “Stratasys is well-positioned to provide production and manufacturing solutions that are resilient, empower local supply chains, and most importantly save lives.

“For example, during the pandemic we were able to repurpose our ecosystem to support the design, manufacture and delivery of vital personal protective equipment and ventilator parts to the healthcare industry.”

Stratasys’ sustainability efforts

Fresh from announcing it hadbeaten its own revenue guidanceduring Q2 2021, Stratasys has identified four SGDs as the foundation of its sustainability endeavour. During 2022, the company will focus on achieving responsible consumption and production, innovation and infrastructure, taking climate action, and ensuring the delivery of quality education.

Around the world, natural resources are continually being used unsustainably. Achieving more responsible consumption and production patterns will require companies to make sure their chemical waste is managed in an environmentally-sound manner, their general waste is disposed appropriately, and that production materials are used as efficiently as possible. Stratasys has committed to innovating new ways of reducing waste, reusing materials, and utilizing recycled packaging in order to meet this challenge.

The second goal the company has identified centers around industry, innovation and infrastructure. Stratasys will seek to ensure 3D printing benefits people across the globe by providing designers, engineers and manufacturers with local, on-demand additive manufacturing capabilities that can be leveraged to improve quality of life through job and wealth creation, research and innovation, and entrepreneurship support.

Regarding climate action, Stratasys has committed to reducing not only its own carbon footprint but also that of its customers when using its products. The company will do this through playing its part in reducing global shipping by providing companies with more efficient digital manufacturing methods.

Lastly, Stratasys has pledged to ensure inclusive and equitable quality education and learning opportunities for all, particularly students. The firm will provide ‘learning by making’ opportunities to give students the literacy and technical skills to achieve rewarding careers in additive manufacturing.

“Beyond the global pandemic, climate change is a growing worldwide concern,” said Zeif. “It is our mission to translate our leadership in 3D printing into mindful business applications for our customers – where less waste is produced, and more value derived from the digital processes that drive our manufacturing solutions. This approach is aimed at assisting our customers in reducing their carbon footprint, with less dependency on mass shipment of inventories and parts, shortening and localizing supply chains across industries such as aerospace, automotive, healthcare and consumer products.”

Joining the AMGTA

As part of its sustainability commitment, Stratasys has joined the AMGTA as a Founding Member, with Coblens serving on the organization’s Board of Directors. The AMGTA was co-founded in 2019 bySintavia,Taito Nippon Sanso CorporationandQC Laboratories, with the core aim of promoting the green credentials of 3D printing and advancing sustainability within the industry.

In November last year, afurther 12 3D printing companies joined the association, having been selected to promote the environmental benefits of additive manufacturing in favor of traditional manufacturing techniques. Spanning a wide spectrum of industries, the new members included the likes ofGE Additive,实现,Siemens Digital Industries, andEOS, among others.

Shortly afterwards, the AMGTA published its first commissioned university research paper on theenvironmental effects of metal 3D printingin comparison to traditional manufacturing methods.

“Stratasys公司创始成员地位至关重要our organization’s mission to advance sustainability in additive manufacturing as we secure a selective group of market and industry experts to represent and advance our work to report on the environmental benefits of additive manufacturing,” said Sherry Handel, Executive Director of the AMGTA.

“Our goal is to introduce new lifecycle analysis research projects in additive manufacturing that clearly measure impact and increase the world’s understanding of 3D printing as critical to the global manufacturing industry’s move towards greater sustainability.”

Increased sustainability focus in AM

Multiple companies have begun to realize thesustainability benefits of leveraging 3D printingfor their manufacturing operations.

For instance, global transit manufacturerWabtecoutlined how integrating additive manufacturing had helped it to improve its environmental performance in its2020 Sustainability Report, while fluid power systems manufacturerDominhas deployedRenishaw’smetal 3D printing technology to produce components that couldhelp slash carbon dioxide emissionswithin the fluid power sector.

Meanwhile, numerous companies within the 3D printing industry have committed to improving sustainability within manufacturing. Binder jet 3D printerExOne, for example, has launched its#MakeMetalGreensocial media campaign to promote the sustainability of its metal binder jet 3D printers, and EOS has been selected as part of the50 Sustainability and Climate Leaders initiative, an international business community seeking to combat climate change.

Elsewhere, there has been a flurry of activity in therepurposing of waste for 3D printing materials, the development offully biodegradable filamentsandrecyclable powder materials, and addressing resource efficiency bysubstituting fossil-based materials.

Nominations for the2021 3D Printing Industry Awardsare now open, have your say who is leading the industry now.

Subscribe to the3D Printing Industry newsletterfor the latest news in additive manufacturing. You can also stay connected by following us onTwitterand liking us onFacebook.

Looking for a career in additive manufacturing? Visit3D Printing Jobsfor a selection of roles in the industry.

Subscribe to ourYouTube channelfor the latest 3D printing video shorts, reviews and webinar replays.

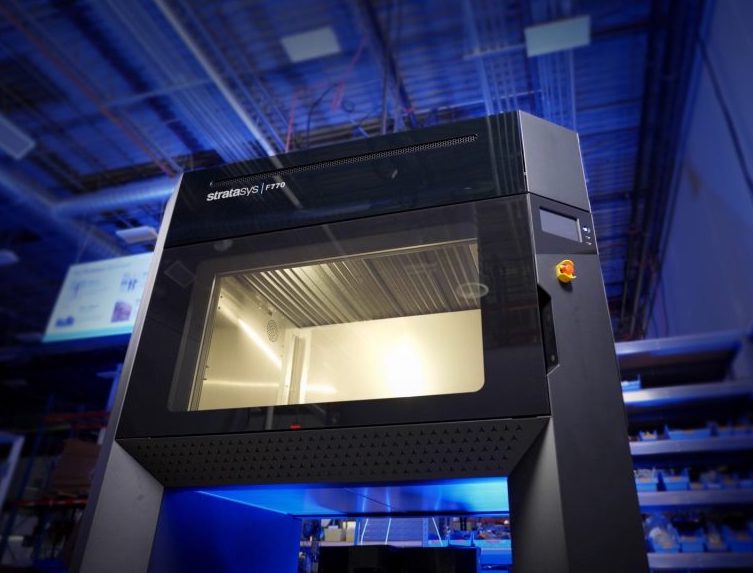

Featured image showsStratasys launched five new 3D printers during Q2 2021, and is preparing further product releases for H2 2021. Image via Stratasys.