Belgian 3D printing software developer and service providerMaterialise已宣布将本机CAD工作流功能添加到其魔术平台。

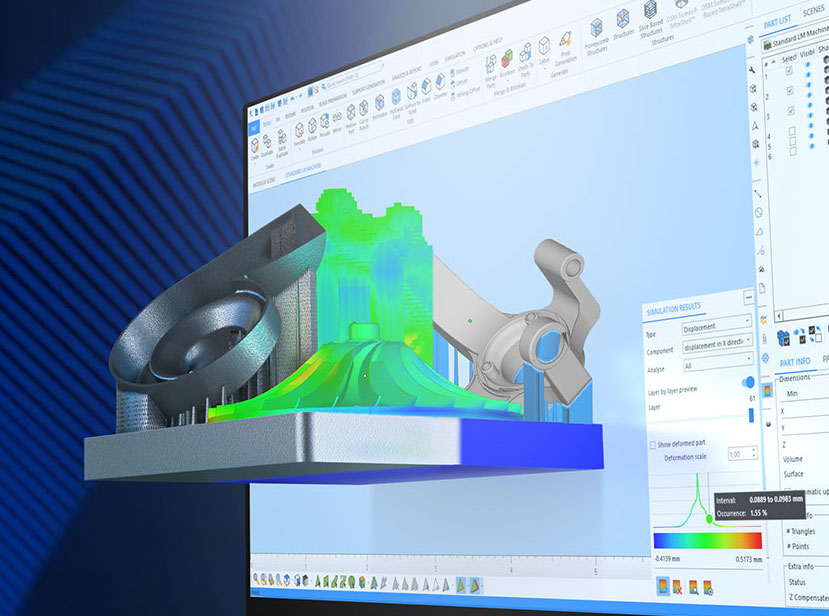

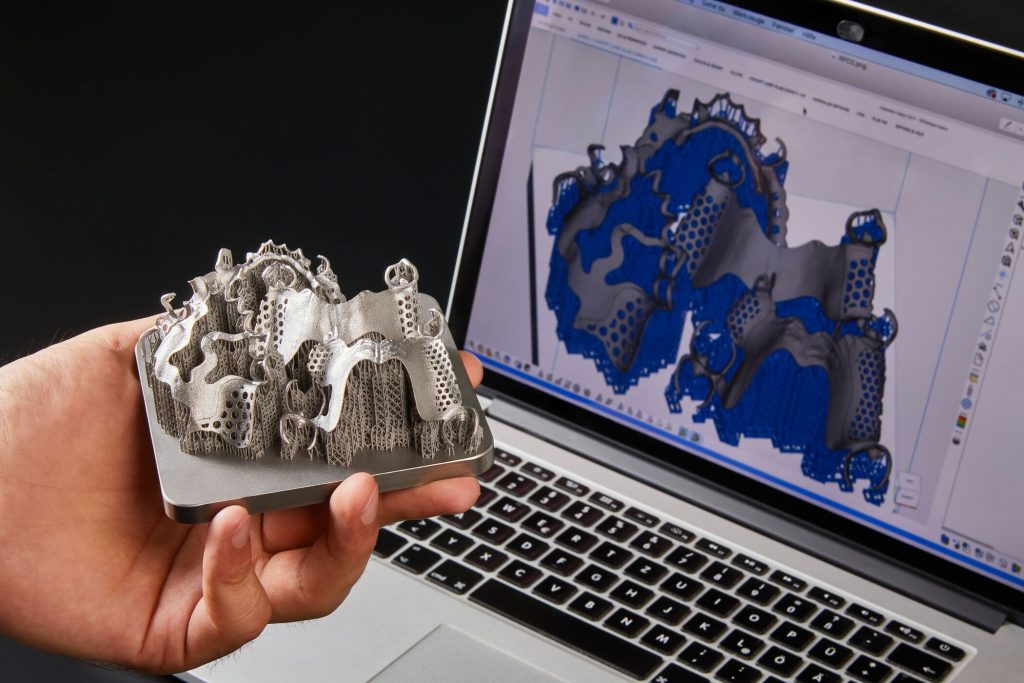

与西门子'寄生虫software, Magics users will soon be able to switch seamlessly between CAD and mesh workflows, and continue iterating upon designs without having to leave the program. According to Materialise, this upgrade could also enable adopters to better prepare parts for 3D printing, upping their productivity, while yielding “more accurate and fit-for-purpose build data.”

“多年来,3D印刷行业一直讨论了CAD还是网格是文件准备的首选工作流程,” Materalize Software副总裁Stefaan Motte解释说。“我们认为,两种格式的无缝集成都可以为用户提供最佳的工作流程。”

Materialise’s modular offering

尽管Magics是名义上实现的专有构建准备软件,但它提供的不仅仅是切片功能,还为用户提供了简化的端到端工作流,从直接导入设计文件到最终报告。

无论用户是操作PBF,SLS,MJF,SLA,Binder Jetting还是EBM机器,Magics都可以通过其自动固定和晶格工具来维修,编辑甚至增强零件。该平台还具有简化的筑巢,自动支持生成和内置分析公用事业,旨在使其使用时间较少的功能,并允许用户识别缺陷并避免流产的印刷品。

Since launching Magics, Materialise has continually upgraded its software offering, first adding a金属添加剂模拟模块, 前launching a dental add-on这是为了加快正畸印刷准备的加快,现在概述了将其提升到一个新水平的计划,并随着明年的寄生虫的整合。

魔法获得了另一个维度

由开发西门子的数字工业软件部门,寄生虫被销售为世界领先的几何3D建模内核。作为公司更广泛的一部分工作Xceleratorportfolio, the software provides a range of modeling capabilities, including solid modeling, direct editing and free-form surface/sheet modeling, to those engaged in product design, simulation and manufacturing.

寄生虫now has more than 150 users in sectors ranging from automotive to construction, thus its offering is similarly broad, but its modelling features can generally be broken into designer, editor and communication functions. While the former is designed to enable users to create, manipulate and store demanding models, the latter are meant to facilitate downstream editing, repair and display.

该计划还采用了西门子的收敛建模技术,该技术使网格数据和传统的CAD几何形状都可以在完全汇总的环境中混合。在此过程中,该软件消除了在不同格式之间翻译数据的需求,该过程可能会耗时且容易出现错误,同时允许用户有效地简化其制造工作流程。

By adding Convergent Modeling technology into Magics, Materialise says that its customers will be able to “benefit from the best of both worlds” moving forwards, and use CAD data to edit part designs before switching to mesh for platform preparation, in a way that allows those engineers more familiar with the former, to edit their parts with greater confidence.

Known as ‘Magics 26,’ Materialise adds that its upgraded platform is set to be released in spring 2022, at which point it will “power additive manufacturing champions with a cohesive and fully-integrated workflow for 3D printing.”

Siemens in the 3D printing industry

While the integration of Parasolid will no doubt be good news for Magics fans, it’s far from the first time that Siemens’ software has been utilized within 3D printing. In June 2021, for instance, car manufacturerVolkswagenannounced plans to use the company’s programming to优化其工厂的生产率在沃尔夫斯堡,生产中正在部署Binder Jet 3D打印。

西门子也是如此expanded its existing partnershipwithEOS北美今年早些时候,旨在提高采用工业化3D打印的目的。作为公司扩大合作的一部分,EOS同意于2月开始销售西门子的软件,并为其客户提供了在设计和生产过程之间实现更大连接的方法。

Elsewhere, the firm deploys additive manufacturing itself within its西门子的能量spin-off, which managed to develop a新颖的数字修理链earlier this year. The fully-automated workflow enables features, such as intricate cooling channels, to be 3D printed into the tips of gas turbine blades, that reduce their risk of suffering from cracks or defects.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the3D打印行业通讯or follow us on推特或喜欢我们的页面Facebook。

为了深入研究添加剂制造,您现在可以订阅我们的Youtubechannel, featuring discussion, debriefs, and shots of 3D printing in-action.

您是否正在寻找添加剂制造业的工作?访问3D打印作业在行业中选择一系列角色。

特色图像显示了一个可视化的可视化,描绘了在Mitalize的Magics软件上实现的3D打印零件。通过物质图像。