Nominations for the2022 3D Printing Industry Awardsare now open. Who do you think should make the shortlists for this year’s show? Let us know by casting your vote now.

威尔士生物技术公司JellagenandCopner Biotech已经部署了一种新型的3D生物打印过程,以将从水母胶原蛋白制成的生物企业变成“世界优先”的功能性软组织结构。

Using Jellagen’sCollagen Type 0 bio-inkand Copner Biotech’sGRAPE S1 3D bioprinter, the pair have come up with a process of creating functional tissues from man-made materials and living cells. While many existing bioprinting methods rely on mammalian cells, which can come with ethical considerations, the firms say theirs could offer a less contentious way of engaging in tissue engineering R&D.

“We are delighted with the data outputs of this project that have clearly demonstrated the further potential use of our Collagen Type 0 biomaterials for future bio-ink development,” said Jellagen Founder, Professor Andrew Mearns Spragg. “We are very excited to see how this technology can be further developed towards medical tissue engineering applications and cell culture research market solutions.”

Copner Biotech的葡萄S1系统

Established in 2020, Copner Biotech specializes in the R&D of 3D cell culturing and other related technologies. Initially, all the Welsh start-up had was a concept for a ‘next-generation 3D printing technology,’ potentially capable of creating PETG scaffolds. However, these scaffolds, which require low numbers of cells for seeding, have since exhibited the ability to optimize cell capture and attachment.

This development saw the company presented with the Global Health and Pharma International Life Sciences Award for Innovation in July 2021. Copner Biotech is also said to have entered into “several high-value research projects,” with Welsh Government support, including most recently, its 3D bioprinting work with Jellagen.

正如2021年10月宣布的那样Jellagen和Copner Biotech的合作伙伴关系is to optimize the performance of the GRAPE S1 extrusion 3D bioprinter. The system works by using microfluidic droplet deposition to create layers via sequential printhead movement, in a process that’s designed to yield a high level of print precision and control.

Copner Biotech的下一代BioProinter不依赖传统的STL或G代码文件,而是使用图形矩形实际位置编码或“葡萄”文件。这些程序被编程为解决麻烦的数据近似,建模异常和较低的精度水平,以使可重复的基于可重复的单元结构的生产。

Another benefit of the GRAPE S1 is that it prints via material collected from an open-source microfluidic reservoir, allowing users to utilize cell combinations of their choice. Copner Biotech anticipates that the system’s open-material setup will soon “empower the research community to push the boundaries of 3D bioprinting,” and working with Jellagen, it has now begun realizing the technology’s potential.

威尔士3D生物打印研发计划

According to Jellagen and Copner Biotech, many current bioprinting systems on the market are limited by “dated software protocols,” and rely on mammalian sources of biomimetic materials and living cells. Backed by Wales’ business R&D investor scheme,SMARTCymru, the firms’ project has seen them collaborate since last year, on developing an alternative from Jellagen’s next-generation biomaterial.

由于这种胶原蛋白0型生物企业是从爱尔兰海的桶水母收获的,爱尔兰海迅速成为英国沿海的害虫,因此该公司将其生产定位为维持生物多样性的一种方式。从理论上讲,由于材料是从进化树的根来源的,Jellagen说,胶原蛋白0型比哺乳动物对应物更安全,更纯净,更有效,更有用。

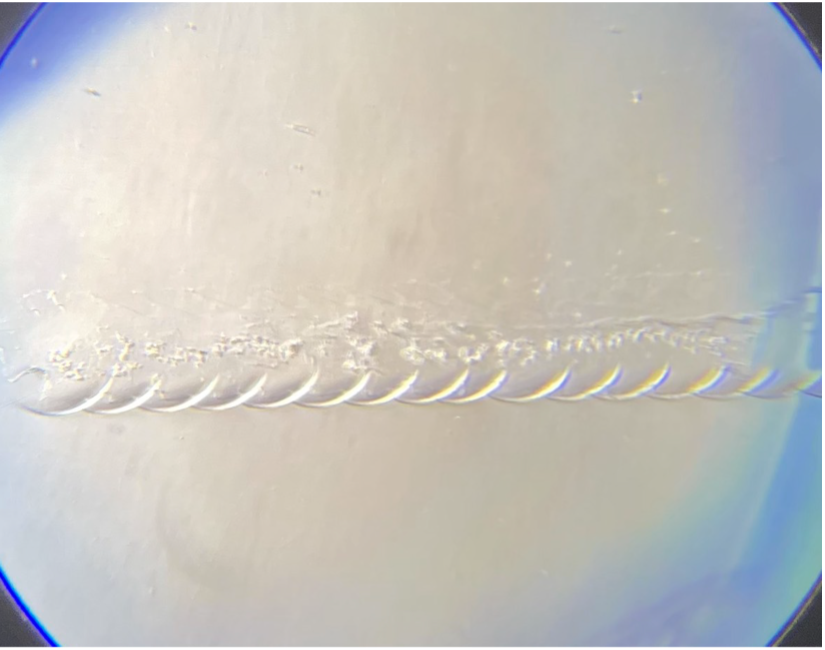

Utilizing Collagen Type 0 as a bio-ink, the companies say they’ve now managed to 3D print very fine, less than 100m diameter tissue structures, on Copner Biotech’s GRAPE S1. In combination with an advanced algorithm, this process is also said to allow for the precise modeling of 3D architectures, to the point they could be made to mimic the organic micro-environments of a living system.

Moving forwards, the project participants believe their workflow could be of particular importance in bioscience R&D, within the creation of repeatable 3D cell culture models. Though not designed to 3D bioprint transplantable structures, Copner Biotech CEO Jordan Copner says the technology it has developed with Jellagen, has the potential to “transform lives through tissue engineering.”

Bio-inks in the field of 3D bioprinting

Cell-depositing hardware isn’t the only area of 3D bioprinting that continues to be the subject of intense research, and scientists have made a number of bio-ink R&D advances in recent years. Researchers at the IrishRCSI University of Medicine and Health Scienceshave come up with awound-healing 3D bioprinting inkthat can be turned into regenerative tissue scaffolds, which mend skin without scarring.

这是在开发新的silk-based 3D printing bio-inkat Japan’sOsaka University, which was said to enable the fabrication of cell-laden structures with improved printability. During testing, the scientists’ material was found to minimize the internal stresses placed on cells during 3D printing, which improved their survivability and allowed them to retain complex bio-mimicking shapes.

More recently, a team at康奈尔大学设法开发了3D可打印的生物杂交复合材料可以用来创建人造皮肤,从而复制其现实生活中的行为。柔软和生物相容性,但也足够灵活以承受持续的失真,人们认为这些材料有一天可以用来从患者的细胞中造成脚手架,这些细胞可治愈可治愈伤口的原位。

要了解最新的3D印刷新闻,请不要忘记订阅3D Printing Industry newsletter或跟随我们推特or liking our page onFacebook.

While you’re here, why not subscribe to ourYouTube渠道?包括讨论,汇报,视频短裤和网络研讨会重播。

Are you looking for a job in the additive manufacturing industry? Visit3D Printing Jobs在行业中选择一系列角色。

Featured image shows a 40X magnified image of a 3D bioprinted Collagen Type 0 structure. Photo via Copner Biotech.