The3D打印行业Awards 2022shortlists are now available for voting. Who will win the 2022 3DPI Awards? Have your say by casting your vote now.

Researchers at five Fraunhofer research institutes have combined 3D printing with AI to develop a unique way of producing patient-specific finger joint implants.

作为“ FingerKit”项目的一部分,该团队提出了一个自动植入的设计过程,其中部署了AI以将2D X射线图像转换为3D指模型。据说这种新颖的工作流程不仅可以纠正任何手指定位问题,而且可以促进产生光滑,无摩擦的植入物,并减少了可以用精度喷射的后加工需求。

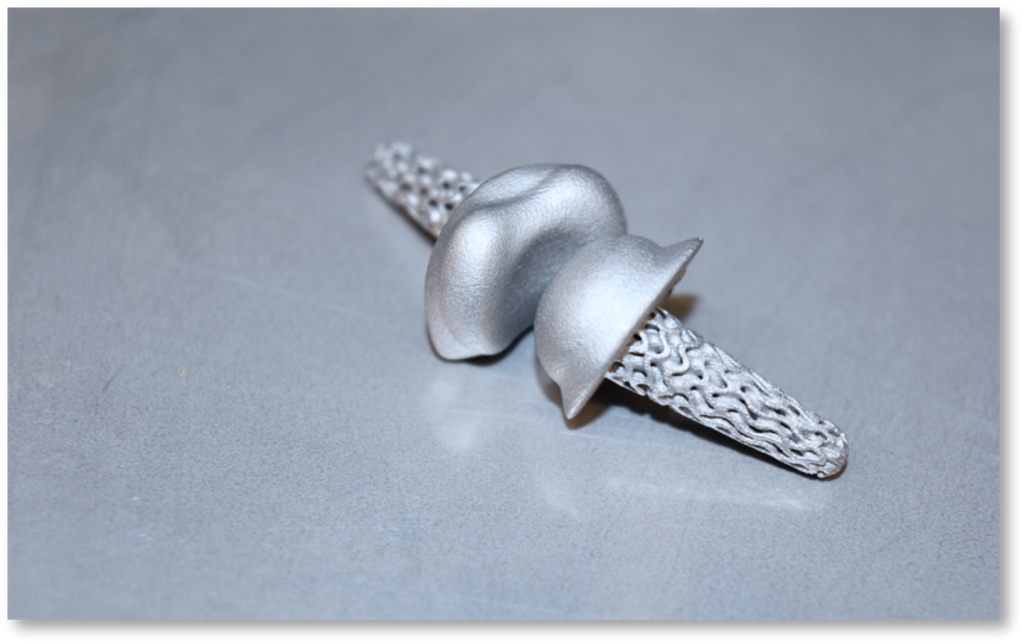

“由于植入物轴的结构非常精致,我们选择将金属粘合剂喷射3D打印方法用于钛,” Fraunhofer IAPT AM Process资格部负责人Philipp Imgrund博士解释说。“这种方法允许非常精确的小型植入物生产,还使我们能够以更有效地生长到骨骼的方式中构造轴的表面。”

AI-driven implant 3D printing R&D

According to the Fraunhofer team, finger injuries or illnesses like rheumatoid arthritis can “put serious limitations on someone’s life and cause them physical and mental strain.” This is especially the case for people whose jobs involve intricate hand movements like musicians or surgeons, who could face an end to their careers.

At present, many treatments see patients’ joints fused, something that can place severe restrictions on their day-to-day life. Where implants are used, they either tend to be basic and not allow for a full range of movements, or be made from silicone, meaning they can quickly come loose and need to be reattached in another procedure.

为了解决这个问题,Fraunhofer Research Institution for Additive Manufacturing Technologies IAPT, theFraunhofer Institute for Ceramic Technologies and Systems IKTS, theFraunhofer Institute for Toxicology and Experimental Medicine ITEM, theFraunhofer材料力学研究所IWM和theFraunhofer数字医学研究所MEVIS试图开发新的患者特异性植入物。

为了提出一个完美的解决方案,该解决方案不会脱落并将患者的关节恢复到以前的活动水平,这五个机构已经开发了一种新型的自动化过程链。该工作流的中心是Fraunhofer Mevis-Honed AI,它能够从3D指模型中得出单个植入物设计,并自动将其发送以进行3D打印。

一旦在Fraunhofer Ikts打印了Binder Jet 3D(或用陶瓷制成时施放的滑动),这些植入物就会烧结,使它们具有接近网的形状和最小的整理要求。虽然Fraunhofer物品正在处理有关植入物的生物相容性和证明的问题,但它们很快就可以用来治疗弯曲的手指,缺失的骨头或小手接头。

研究人员的计算表明,可能有可能减少从植入物生产到拟合所需的时间,最多可达60%,并使该过程能够在几天内完成。与脚部或踝关节植入物相比,团队还认为,关节重新启动的市场“仍然显着不发达”,他们引用了“专家预测”,即到2026年可能会达到580万欧元。

鉴于他们的研究中未开发的潜力和最新发展,科学家现在正在寻求与商业合作伙伴合作,将其植入物印刷工作流程推向市场,并寻求设备认证以简化流程。

3D printing in finger joint repair

可植入的3D印刷关节可能具有巨大的未开发市场潜力,但是弗劳恩霍夫的研究人员并不是唯一寻求利用这一优势的人。去年年底,比科和Nanochonunveiled plans to develop3D printed regenerative joint implantsthat could deliver faster recoveries for patients while reducing costs to healthcare providers.

在过去,纠结has also come up with a means of使用AI到3D打印个性化植入物。两年前该项目揭幕时,该公司承诺使用GE AdditiveArcam的电子束熔化技术以及通过可穿戴设备收集的术中和术后数据的计算机化分析,以开发膝盖置换。

Elsewhere, for those with severe hand injuries, scientists at the布里斯托尔大学have developed a3D印刷人工指尖有可能使截肢者通过假肢“感觉”对象。随着进一步的研发,小费背后的团队说,它可以彻底改变机器人技术的世界,或者有助于提高肢体义务的人的控制。

要了解最新的3D印刷新闻,请不要忘记订阅3D打印行业newsletter或跟随我们Twitter或喜欢我们的页面Facebook。

While you’re here, why not subscribe to ourYouTubechannel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit3D Printing Jobsfor a selection of roles in the industry.

Featured image shows an X-ray of a patient with rheumatoid arthritis. Image via Fraunhofer-Gesellschaft.