The2021 3D Printing Industry Awardsshortlists are open for voting, have your say now.

3D printing software developerDyndritehas introduced a new enhanced Raster and Vector Toolpathing API that enables the creation of transparent and shareable toolpathing recipes.

The toolsets are now available for license by machine OEMs and end-customers seeking to develop and qualify new machines, materials and geometries, without requiring them to reveal their intellectual property (IP) or employ large software teams.

The Toolpathing API also enables these companies to develop print recipes for builds that were previously impossible or difficult to print.

“Generating toolpaths, or instructing a machine on exactly how to build your part, is critical to that part’s ultimate success, especially as the types of parts, materials, and machine capabilities advance,” said Harshil Goel, CEO of Dyndrite. “Machine makers and their customers require more sophisticated tools to be able to consistently deliver quality parts, especially, for example, heat exchangers, turbines, and other difficult-to-print geometries, at faster speed.

“The innovations being delivered by Dyndrite far surpass the capabilities of even the most advanced OEM-developed software offered today, and is only the beginning of a much requested and long overdue industry shake up.”

Dyndrite’s AM software capabilities

Dyndrite was founded in 2016 and operated in stealth mode for three years while developing its fully GPU-native geometry engine, the DyndriteAccelerated Geometry Kernal (AGK). Soon after, the firm launched itsAdditive Manufacturing Toolkit (AMT)at AMUG 2019, designed to facilitate a streamlined CAD-to-Print workflow for industrial additive manufacturing.

Utilizing AGK, Dyndrite’s AMT program is capable of handling specific computations such as lattices, supports, and slice generation with ease, which reduces any time wasted on redesigning parts.

Since then, Dyndrite has sought to ramp up the wider adoption of its software through itsDeveloper Program, created to provide tools and resources for users of its AGK. Founding members of the development program includedEOSandHP, and now includes the likes of3D Systems,SLM Solutions, andExOne.

In August last year, Dyndriteextended its strategic partnership with HPto license its AGK to for use with the multinational printing firm’s next-generation additive manufacturing portfolio. A few months later, the two firms announced the development of HP’sUniversal Build Manager(UBM), which is powered by Dyndrite and leverages the firm’s GPU-accelerated geometry engine.

The UBM is designed to help HP’s customers to simplify, automate, and speed up build preparation across their 3D printing workflows, while enabling the mass-customization of parts, complex workflow automation, and scalability.

Most recently, Dyndritelaunched a new set of software APIsdesigned to enable 3D printer manufacturers to more easily implement advanced features such as support-free 3D printing. The toolsets were developed in partnership with the firm’s Developer Council and OEM customers, and are available as part of Dyndrite’s Accelerate Computation Engine (ACE) Toolpathing API.

Dyndrite’s Raster and Vector Toolpathing API

The latest toolsets from Dyndrite are available for license by 3D printer OEMs developing raster (DLP, LCD, binder jetting) or vector-based (DMLS, SLM, SLS) processes, and who are looking to accelerate the development and qualification of new machines, materials and geometries without being forced to reveal their IP.

According to Dyndrite, for additive manufacturing to support serial production, toolpathing needs to be more sophisticated and automated. As such, the firm’s new Toolpathing API delivers capabilities that the 3D printing industry has long-requested, and which it says other toolpathing offerings fail to detect. One important feature of the API is its 3D Volumetric Part Segmentation for the detection of upskins, downskins, inskins, and other features.

据报道,这个新功能超过现有的layer-by-layer-based boolean toolpathing methodologies, which typically provide a “2.5D” look into a part, by leveraging its GPU-based voxel engine to enable true 3D geometric queries. The True 3D Segmentation capability enables volumetric assignment of parameter for each segment of a part based on several variables, such as distance from upward or downward faces, while also avoiding inefficient “2.5D” calculations.

The toolpathing capability also generates “feature-aware” machine tiles while using geometry to determine finely-graded process parameters and make accurate calculations. Additionally, the True 3D Segmentation can create an unlimited number of thresholds to deliver accurate parameters for different build conditions, and assigns colors to distance thresholds to ensure the correct parameters are deployed for challenging geometries like thin walls and overhangs.

“True volumetric analysis enables us to identify features that cannot be found using 2.5D analysis of layer data,” said Steve Walton, Head of Product at Dyndrite. “It also allows us to develop more sophisticated toolpath strategies in the vicinity of fine features that are generated using any method: CAD Geometry, Mesh data from 3D Scanning, or Implicit Geometry.

“This goes far beyond layer booleans used to determine upskin and downskin. Now we can use 3D fields to assign parameters throughout the build.”

Additional features of Dyndrite’s Toolpathing API

In addition to the 3D Volumetric Part Segmentation, Dyndrite’s new Toolpathing API also allows the offsets to be applied to outer contours and zones to improve the accuracy of parts. The API also assigns geometric and tool parameters to each zone, segment type, and layer within a part, and can programmatically apply tiling parameters regardless of how many zones are in place.

The API is further capable of applying process tiling and micro hatching geometry to prints, while merging, sorting and filtering previously created tiles to determine tool use and exposure based on metadata filters, queries, sorting, and machine constraints like gas flow.

“Users don’t want black box solutions,” said Goel. “Lack of transparency and democratization is holding the additive industry back, and it is Dyndrite’s goal to shake things up by bringing advanced toolpath development and mathematics right to the users’ fingertips. The users of additive manufacturing devices are often much more sophisticated than the machine vendors give them credit for and the ‘secrets’ are preventing adoption, success, and qualification ofr new applications.

“This knowledge should not be locked away by existing large or newer machine vendors.”

Subscribe to the3D Printing Industry newsletterfor the latest news in additive manufacturing. You can also stay connected by following us onTwitterand liking us onFacebook.

Looking for a career in additive manufacturing? Visit3D Printing Jobsfor a selection of roles in the industry.

Subscribe to ourYouTube channelfor the latest 3D printing video shorts, reviews and webinar replays.

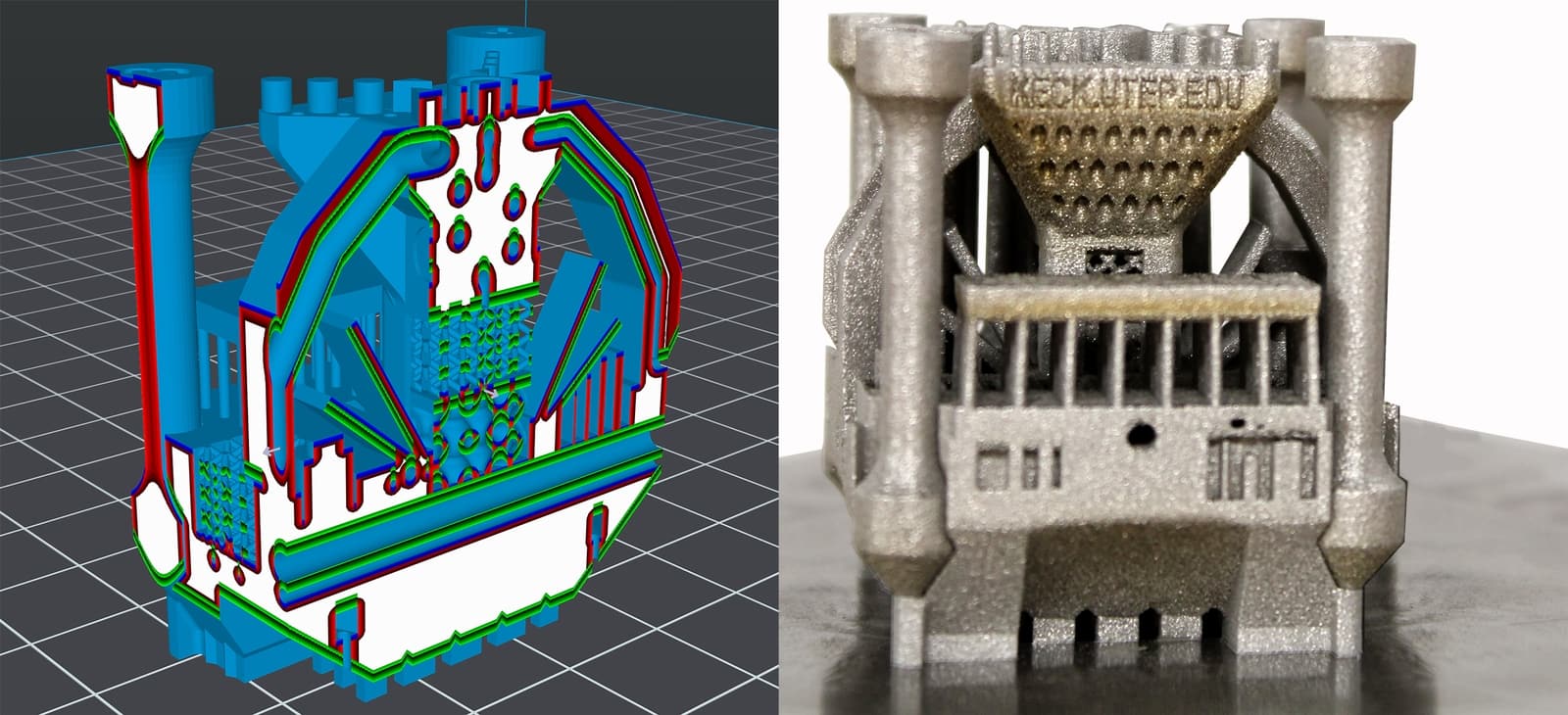

Featured image showsDyndrite’s Raster and Vector Toolpathing API. Image via Dyndrite.