碳3Dmaterialized out of nowhere at the TED conference yesterday and introduced a whole new approach to polymer-based 3D printing that might in fact be the leapfrog innovation we’ve all been hoping to see come into existence. The newContinuous Liquid Interface Production技术(剪辑)使用光和氧气“从树脂池中连续生长物体,而不是逐层打印它们”。因为我知道每个人都会立即想知道它的成本:they didn’t release that information yet.

3 Insanely Cool Things About Carbon 3D’s CLIP Technology:

- 心灵吹速:25-100 times faster than conventional 3D printing

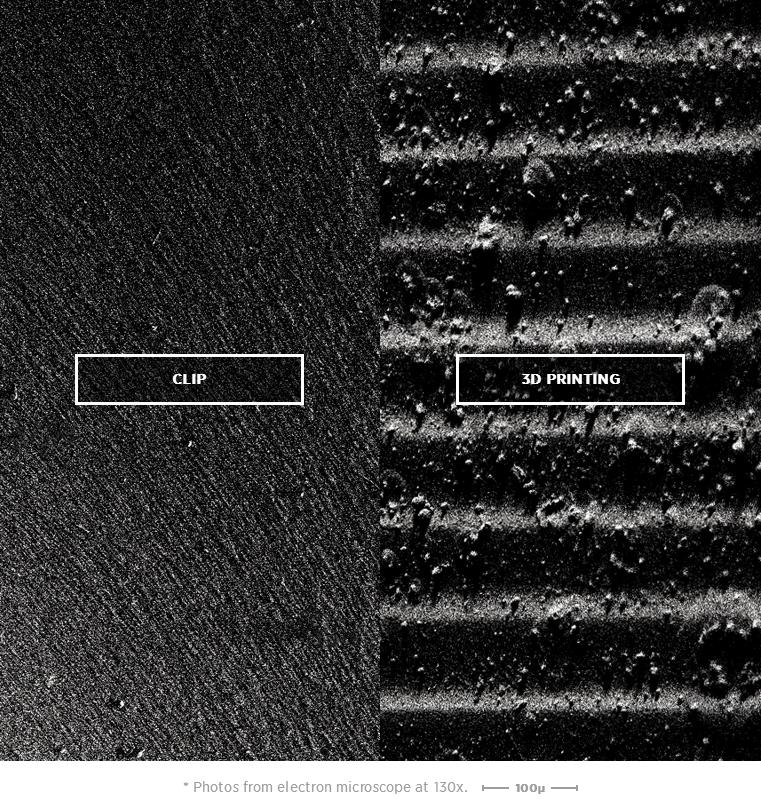

- Commercial Quality:产生具有一致机械性能的对象

- Material Choice:实现了多种聚合物材料

Carbon3D的首席执行官兼联合创始人Joseph Desimone博士说:“当前的3D打印技术未能兑现其对革新制造业的承诺。我们的剪辑技术提供了改变游戏的速度,一致的机械性能以及复杂商业质量零件所需的材料的选择。”Desimone博士是一位了不起的科学家和企业家,也是众多奖项的获得者,包括Lemelson-Mit发明家奖和2009年NIH导演的先驱奖。Desimone博士还获得了100多种已发行的专利和近300篇已发表的文章。

仔细研究夹技术的工作原理:

We know that 3D printing, as it exists today, works by printing or curing one layer at a time. Instead of this layer-by-layer approach, the Carbon 3D printer uses “a tunable photochemical process.” What this means is that, by carefully controlling the interaction of UV light, which creates the photopolymerization, and oxygen, which inhibits the reaction, CLIP continuously grows objects from a pool of resin at speeds 25-100 times faster than traditional 3D printing!

关键组件是一个特殊的窗口,既透明又透明且可渗透到氧气,类似于隐形眼镜。通过平衡窗户进出的氧气量,夹子在树脂池中产生一个“死区”,在树脂池中仅是数十微米厚的,而光聚糖不可能发生。然后,一系列“ 3D模型的横截面图像像电影一样从下面播放到树脂池中”,并且物理对象刚刚出现(就像来自T的T-1000Terminator 2) from just above the dead zone.

What’s truly phenomenal about this approach is that it seems to have created a technique that yields parts with the structural integrity of injection molded parts, at least according to Carbon 3D. The mechanical properties would often vary depending on the direction of the prints layer-by-layer. I haven’t seen it up close, and I’ve reached out to find out more information, but Carl Bass mentioned this atReal 2015(没有提及公司的名字 - 对我的恼火)。如果他们说的是真的,那就是一个突破。新的剪辑可以解决三个大障碍(速度,价格,可靠性)中的两个,因为它可能会产生更一致,可靠和可预测的机械性能。它在外面很顺利,而且内部完全坚固,仅此一项就可以改变游戏规则。

自2013年以来,Carbon3D在接近完美的隐形模式下已筹集了4100万美元的资金,从Sequoia Capital,在2013年拥有A系列融资,以及Silver Lake Kraftwerkfor their series B round.

Jim Goetz, Carbon3D board member and Sequoia partner said, “If 3D printing hopes to break out of the prototyping niche it has been trapped in for decades, we need to find a disruptive technology that attacks the problem from a fresh perspective and addresses 3D printing’s fundamental weaknesses. When we met Joe and saw what his team had invented, it was immediately clear to us that 3D printing would never be the same.”

Some of the key figures behind this major 3D printing breakthrough are: Professor Joseph DeSimone (Chancellor’s Eminent Professor of Chemistry at UNC), Professor Edward Samulski,(Cary C. Boshamer Professor of Chemistry at UNC) and Dr. Alex Ermoshki (CTO and Co-founder).

We’ll keep you posted as the story develops!