Interested in reading more about the year’s biggest 3D printing news? You can access our full3D打印行业Review of the Year系列在这里。

9月看到了国际制造技术展(IMTS) at McCormick Place in Chicago. While usually held every other year, the COVID-19 pandemic meant this year’s edition was the first since 2018. As such, the event doubled up as both a chance for production technology developers to showcase their latest products and for attendees to network and reconnect.

Away from the 3D printing business world, which also saw significant moves from Nikon and 3D Systems, researchers unveiled technological advances with the potential to create future manufacturing opportunities. Construction 3D printing made progress, too, not just in the lab but in practical applications, with the UK getting its largest ever 3D printed infrastructure.

阅读更多有关碳,尼康,3D系统,系统生物,香港城市大学,Optisys,Optisys,Hybrid Manufacturing Technologies,SLM解决方案,英国国防部,Changemaker 3D,BAM,Weber Beamix和弗吉尼亚大学的更多信息。

IMT从共同诱导的中断返回

与往常一样,今年的展览允许3D打印公司直接与其他制造技术(如注射成型或CNC加工)的开发商一起展出。这提供了一个难得的机会来权衡3D打印的未来,确定其在更广泛的制造世界中的位置,并查看最新进展的来源。

As discussed in3D打印行业’s IMTS breakdown,活动的标题公告之一是发布HP’s Metal Jet S100 3D printer。The firm’s long-awaited entry into the metal 3D printing space is designed to work with Metal Injection Molding (MIM) materials rather than spherical powders. At the time, it was said this would allow system users to drive down their cost-per-part.

nexa3d还推出了其新的高吞吐量QLS 820 3D打印机,而Inkbit展示了今年早些时候推出的Vista机器,并配备了一种算法,该算法使其达到了当时的World Record build板密度为42%。

别处,3D系统showed off Certified CuNi30, a corrosion-resistant copper-nickel alloy initially designed for亨廷顿·英格尔斯工业子公司Newport News,此后得到了更广泛的发布。同时,在软件中Oqton’s首席执行官本·施劳文(Ben Schrauwen)概述了他公司的软件如何首次找到牙科应用程序,但现在正在获得能源和石油和天然气的吸引力。

尼康(Nikon),3D系统采取战略举动

Following itsSLM解决方案的6.22亿美元出价在本月早些时候尼康收购了Optisys的股份和混合制造技术。These deals saw the company increase its stake in metal 3D printing and take another step towards the digital manufacturing-led goals outlined in its Vision 2030 program.

3D系统,,,,on the other hand,旋转其3D生物打印子公司全身生物。准备利用作为其母公司的一部分开发的技术打印到灌注计划以及其他子公司的计划Alevi,,,,the company is developing tissues for a human vascularized integrated organ system (h-VIOS) platform.

3D Systems首席执行官Jeffrey Graves博士说:“在形成系统性简历时,我们正在应用这些核心技术来特别满足制药市场中的关键需求。”“由于我们有可能最终生产数百甚至数千种定制设计的专有人类组织模型,因此制药公司可以更快,准确地评估实验室中发育药物的功效,目的是减少开发时间。”

建筑势头继续建造

在施工领域,增材制造业在9月在多个方面取得了收益。BAM和Weber Beamixbuilt a3D printed footbridge over a UK motorwayin a process that was thought to lower the structure’s carbon footprint, reduce any risk of disruption and keep down costs by minimizing the use of molds.

Also in the UK,Changemaker 3D与废水服务提供商合作联合公用事业到3D打印1.8米的废水室。通过增材制造桥CYBE构造技术,两人还设法使建造更安全,除了将其交货时间大幅减少到不到四个小时。

别处,in more experimental applications, researchers at the弗吉尼亚大学(UVA)揭开了一本小说3D打印活土壤的方法that could be used to construct future carbon-negative buildings. With further R&D, the UVA team said their seed-impregnated soil ‘ink’ could replace less sustainable construction materials.

美国和英国转向国防

9月出现的另一个趋势是强烈的兴趣英国国防部(mod)和美国国防部(国防部)在军事应用中采用3D打印。那个月,SLM解决方案宣布已被分包并发技术公司开发“世界上最大的金属3D打印机”用于部署美国空军。

In essence, the firm revealed that it was working on a new version of itsNXG XII 600 3D打印机带有1.5米的Z轴。即将被称为“ NXG XII 600E”,即将到来的系统旨在克服当前添加剂制造设备的限制,以创建具有关键防御应用的长零件。

在英国,宣布MOD制造供应商网络was in the process of being established, with the ambition of enabling military-grade spare parts to be 3D printed on demand. As part of‘Project TAMPA,’该mod的目的是创建一个多供应框架的框架,其容量可以在需要时更轻,更强的金属零件。

揭示下一个3D打印进展

因此,通常在3D打印中,大突破来自大学开发的技术,并且整个月都揭幕了几个此类项目的结果。在香港城市大学,科学家提出了一种部分碳化零件的方法使3D打印晶格更强100倍。

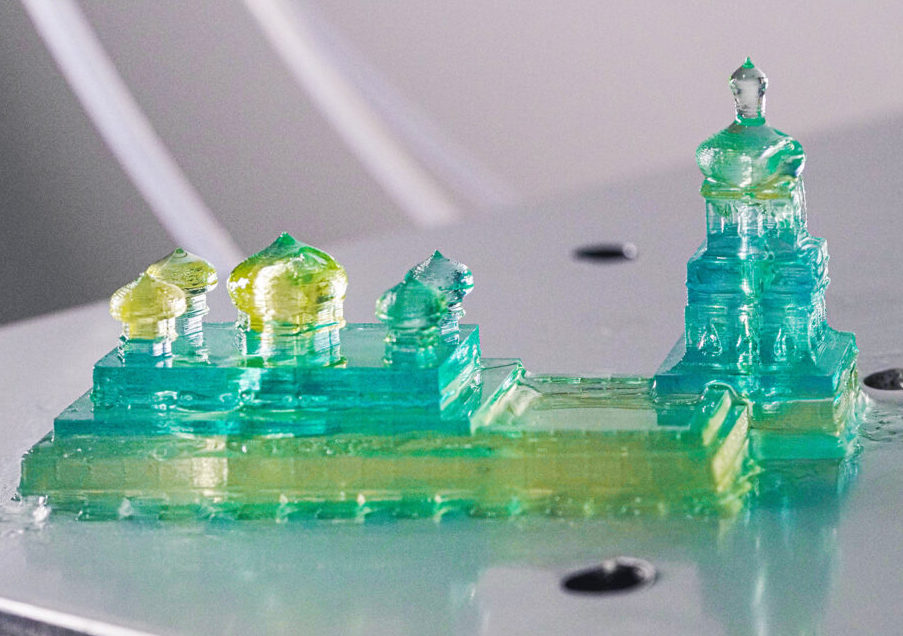

研究人员在斯坦福大学also announced the development of a“快五到十倍”树脂3D打印过程。实质上是对连续液体界面生产(夹子)方法的新鲜措施碳,,,,the team’s ‘iCLIP’ approach sees the oxygen-filled ‘dead zone’ at the bottom of a CLIP printer’s resin pool repurposed.

通过将额外的材料泵入这个空间,科学家设法加速了该过程并解锁了独特的导管集成零件设计。碳Co-Founder Joseph DeSimone, who turned out to be one of the co-authors of the team’s study, said the technology could “help to usher in a new era of digital manufacturing,” and “enable the fabrication of complex, multi-material objects in a single step.”

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the3D打印行业通讯或跟随我们Twitter,,,,或喜欢我们的页面Facebook。

当您在这里时,为什么不订阅我们Youtubechannel? featuring discussion, debriefs, video shorts and webinar replays.

您是否正在寻找添加剂制造业的工作?访问3D打印作业在行业中选择一系列角色。

特色图像显示了IMT 2022的故乡McCormick Place入口处的楼梯。PaulHanaphy摄影。