来自康科迪亚大学, Montreal, are exploring the 3D printing of graphene oxide liquid crystals to enable materials with previously-unseen levels of strength.

Having made headlines for over a decade, graphene is one of those wonder materials that promised to solve a number of our engineering challenges. The sheet-form carbon allotrope comprises a single layer of atoms arranged in a 2D nanostructure resembling a honeycomb lattice. The material is known for its high strength-to-weight ratio, excellent thermal and electrical conductivity, corrosion resistance, and scratch-resistant qualities.

不幸的是,我们尚未能够将石墨烯的强度从微观计算到宏观中的现实应用程序。

Concordia团队现在使用Photocuring,即立体光刻3D打印背后的技术来生产比当今可能性更大,更复杂的自组装石墨烯结构。

Graphene – the strongest known material

安德烈·盖姆(Andre Geim)and Konstantin Novoselov discovered graphene in 2004, winning the Nobel Prize in Physics for their work shortly after in 2010. At just an atom thick, graphene is around a million times thinner than a human hair but offers a Young’s modulus of 1TPa and a tensile strength of 130GPa. This makes it the strongest known material so far.

Although scaling graphene up is still a huge challenge, the self-assembly of graphene oxide sheets into liquid crystals is a promising approach to jumping the hurdle, as these liquid crystals could potentially be transformed into solid macroscopic structures.

Thus far, the self-assembly process has led to a whole host of macroscopic (albeit thin) structures such as paper, fibers, and aerogels. There are a number of methods for producing these structures, including wet-spinning, freeze-drying, and vacuum filtration. While these approaches do work to preserve the ordered structure in the liquid crystal phase, they’re limited in the thickness and complexity of the structures produced.

光化方法

Concordia团队转向摄影作为替代方案。为了制备石墨烯氧化物片,他们首先将石墨烯分散在酒精中,并在商业上可用的光吸剂中混合,称为BIS(4-甲基苯基)碘六氟磷酸盐。这与当今许多3D打印树脂中使用的光吸剂相同。

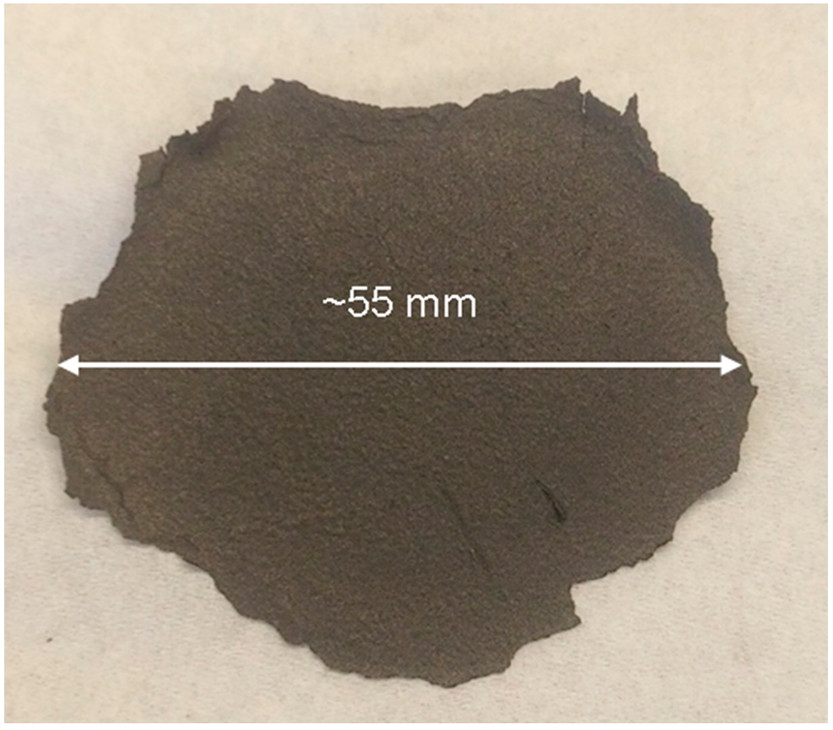

研究人员发现,他们可以成功地将所得混合物固化成薄薄的石墨烯氧化石墨烯,从而将其从液态变成液态到固态。因此,现在认为该方法与3D打印技术兼容。

The novel photocured graphene oxide paper also impressed in a series of tensile tests, exhibiting mechanical properties comparable to those of a benchmark graphene oxide paper, which was prepared via conventional vacuum filtering.

The study writes, “We demonstrate that it is possible to photocure graphene oxide liquid crystals. Photocuring graphene oxide liquid crystals allows for thicker and perhaps more complicated structures than what is possible with current methods such as vacuum filtering or wet spinning.”

Moving forward, the Concordia team would like to adapt the approach to full-scale stereolithography 3D printing in the hopes of fabricating large 3D structures made of graphene.

该研究的更多详细信息可以在标题的论文中找到‘Photocuring Graphene Oxide Liquid Crystals for High-Strength Structural Materials’。

The additive manufacturing of graphene-based materials has certainly been explored before. Researchers from China’s哈尔滨技术学院recently3D printed a soft graphene oxide robot暴露于水分时,能够向后移动。该项目涉及使用直接墨水写作(DIW)3D打印和约束干燥技术,该技术解决了与孔隙,收缩和结构均匀性有关的制造挑战。

在其他地方,来自卡内基·梅隆大学(CMU) and theUniversity of Connecticut(UConn)3D printed novel calcium phosphate graphene (CaPG) scaffolds有一天可以用于骨再生应用。生物打印结构提供了几种理想的特性,例如骨诱导,生物安全,长期的保质期和合理的生产成本。

Subscribe to the3D打印行业通讯有关增材制造中的最新消息。您也可以通过关注我们来保持联系Twitter,喜欢我们Facebook,然后调查3D Printing Industry YouTube Channel。

寻找添加剂制造业的职业?访问3D Printing Jobsfor a selection of roles in the industry.

Featured image shows a large graphene oxide sheet produced via photocuring, the process behind resin 3D printing. Photo via Concordia University.