研究人员在Washington State University(WSU) have developed a material that could be used to 3D print the equipment needed in future missions to explore the red planet.

By mixing titanium with simulated Martian regolith, the scientists have been able to create a feedstock that can be Directed Energy Deposition (DED) 3D printed into structures with greater resistance qualities. Using future iterations of their material, the team say it may be possible to produce tooling or rocket parts on Mars’ surface, rather than flying them there on an expensive-to-launch NASA shuttle.

Economical manufacturing in space

Since the advent of space exploration, the WSU team says “every aspect of space-based operations” has remained very expensive. In fact, citing data from an艾姆斯研究中心报告dating back to 2018, the researchers point out that sending each one-kilo of payload into orbit usingNASA的space shuttle costs about $54,000.

因此,利用原位资源来维持人类勘探对于确保未来任务的经济可行性至关重要。According to one of the study’s co-authors Amit Bandyopadhyay, doing so is not only a necessity as “we really cannot carry everything from here,” but it drives down the chances of any logistical hiccups, as “if we forgot something, we cannot come back to get it.”

As the scientists highlight in their paper, 3D printing continues to be tipped as a means of manufacturing and repairing equipment off-world, but they say certain technologies are less suited to this than others. With DED, for instance, it’s still challenging to print pure regolith structures due to the material’s ceramic content, which has a high melting point, low laser absorption, and is vulnerable to fracture.

These characteristics mean DED-printed regolith parts suffer from severe cracks or pores that cause them to feature poor interfacial strength for coatings. Prior research has also shown that the abrasiveness of Martian dust could impact the viability of future builds. To get around these issues, the team has previously toyed with the idea of stabilizing structures by mixing simulated Martian dust with different forms of titanium, and they now believe they’ve found the ideal material for the job.

Creating a titanium-regolith composite

In an effort to identify the optimal mixture of crushed Martian rock and titanium, the WSU team addedTekna Ti64 powderto different concentrations of regolith simulant, before sieving the resulting granules into various particle sizes.

初始测试表明,装有钛的混合物能够在2mm的现有部件上产生涂料,这比纯岩石可能的200μm覆盖层明显厚。研究人员还发现,由于Regolith和Ti64粉末陶瓷含量之间的“热不匹配”,前者的含量越高,裂纹可能会出现越多。

When it came to strength, the scientists discovered that the addition of simulated Martian dust to titanium allowed it to be 3D printed into structures with twice the microhardness. This, the team believes, is a consequence of the rapid solidification and formation of fine grain microstructures observed in their material upon deposition, as well as cyclic heat accumulation and regolith’s ceramic content.

Moving forwards, Bandyopadhyay says he and his colleagues intend to continue theirNational Science Foundation(NSF)对Regolith复合材料发展的基本研究。通过尝试不同的金属和3D打印过程,科学家最终旨在提出适合生产用于空间应用的轻质负载零件的材料。

Bandyopadhyay总结道:“ [WSU复合材料]为您提供了更好,更高的强度和硬度材料,因此在某些应用中可以更好地发挥作用。”“这确立了这是可能的,也许我们应该朝这个方向思考,因为它不仅是制造较弱的塑料零件,而且还可以使金属陶瓷复合零件强,并且可以用于任何类型的结构零件。”

建立Regolith的3D可打印性

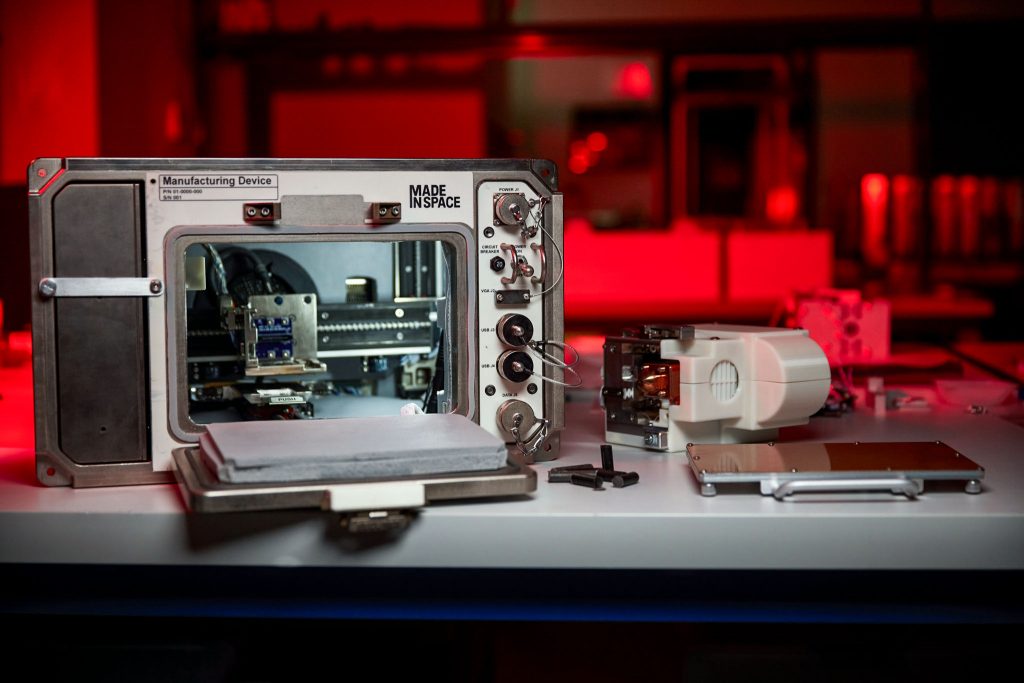

自1972年以来,由于人类从未去过月球,在另一个天体上的3D打印岩石的潜力仍然是假想的,但是在其可行性中进行了相当多的研究。作为去年揭幕项目的一部分,Redwire的Regolith Print Platform已安装在International Space Station,用于测试3D打印的月球构造功能。

在Braunschweig技术大学andLaser Zentrum Hannover, meanwhile, scientists have3D printed lunar regolith under zero gravityfor the first time. Through their experimental project, codenamed ‘MOONRISE,’ the team has already managed to mount a custom laser to a lunar rover, and melt moondust into spherical shapes.

Elsewhere, Texan construction firm图标has been subcontracted to build a3D printed NASA simulated Martian habitat。Developed for long-term mission simulations at美国宇航局的约翰逊航天中心, the 1,700 sq. ft structure’s unveiling closely followed that of a3D printed lunar launch and landing padthe firm built using materials found only on the Moon, the year before in 2020.

研究人员的发现在其论文中详细介绍了“Martian regolith—Ti6Al4V composites via additive manufacturing”,由Ali Afrouzian,Kellen D. Traxel和Amit Bandyopadhyay合着。

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the3D打印行业通讯or follow us onTwitteror liking our page onFacebook。

当您在这里时,为什么不订阅我们Youtubechannel? featuring discussion, debriefs, video shorts and webinar replays.

您是否正在寻找增材制造业的工作?访问3D打印作业在行业中选择一系列角色。

Featured image shows the planet Mars. Image via WSU.