The latest installment of 3D Printing Industry’s series on3D printing and renewable energyfocuses on how additive manufacturing is contributing to decarbonization efforts within the industry.

Metal 3D printing start-upSeurat Technologies,由Porscheand复印,是这样的公司将技术部署到这一目的的一家公司,刚刚宣布其第一个印刷仓库完全由绿色能源供电。

该公司首席执行官兼联合创始人詹姆斯·戴默斯(James DeMuth)说:“增材制造不仅对能源产业有利,而且是基本的。”

DeMuth讨论了Seurat的技术如何推动公司在其自己的制造业务中的脱碳方面的进步,而且还促进了客户的碳足迹,并呼吁行业中的其他人效仿。

根据美国Environmental Protection Agency(EPA), the industrial sector is responsible for24 percent of emissions in the US,这一数字不包括全球运输部件的环境影响。因此,企业需要采取行动,以促进一个更新的,更绿色的制造时代,并由advancement in renewable energy technologiesover the past few years.

Seurat’s Area Printing technology

According to DeMuth, Seurat was founded with the goal of solving manufacturing problems in the energy industry, starting with the LIFE fusion power plant design originated atLawrence Livermore National Laboratory.

“从根本上讲,任何在几何依赖的东西,例如核或太阳能,或使用旋转组件,例如带有涡轮机或压缩机(例如风,水力,潮汐或地热)的任何东西,或能源能源(例如汽车,飞机,飞机,飞机和火车,火车,飞机和火车)的东西添加剂制造能够获得高级设计的好处。” DeMuth说。

区域打印is an LPBF 3D printing process that decouples speed and resolution to overcome common tradeoffs regarding speed, quality, and scale. The technology is the result of decades of laser and optics management stemming from LLNL, where DeMuth co-invented the technology in 2011. He later co-founded Seurat in 2015, and the firm now has over 130 granted and pending patents, as well as an exclusive license on the Area Printing technology.

“Area Printing splits a single, powerful laser beam into as many as 2.3 million separate beams,” explains DeMuth. “Each of the 30kW laser’s pixels can be programmed to either block or let light through. A large area of metal powder can be welded instantly thanks to every pixel effectively defining a laser spot, turning a serial process into one that is massively parallel, ultimately representing a 10 times increase in production rates compared to incumbent 3D printing in the first generation of machines.”

在应用程序方面,该公司的许多客户都处于高批量生产业务的汽车,消费电子,能源和其他工业领域。Demuth说,从根本上讲,区域打印使他们能够扩展生产率,从而使零件的生产成本减少了今天的10倍以上。

“Dropping the cost of parts to below conventional manufacturing methods is essentially the ‘get out of jail card’ that the additive manufacturing industry has been waiting for,” he adds.

脱碳制造

为了脱碳制造,Seurat的区域印刷技术使公司的客户可以偏离铸造过程,这些过程产生的排放量相当于每吨金属一桶油。常规铸造占全球1万亿美元金属部分制造市场的20%,并在此过程中使用天然气和可乐,而天然气和可乐又产生了重大的排放。

The政府间气候变化面板(IPCC) recently sounded a‘code red for humanity’on climate change, prompting Seurat and others to ramp up their efforts toward decarbonization. Area Printing is expected to offset the equivalent of six billion gallons of gasoline, which aligns with the US’ goal of accelerating domestic clean energy manufacturing.

DeMuth说:“到2030年,随着客户加大生产并取代金属铸造生产的应用,我们希望每年最多可抵消2GT的二氧化碳。”“我们正在努力在ISO 14064指南之后验证我们的预测,该指南是一个涉及温室气体排放报告的国际标准,我们很高兴能够成倍地增加我们的积极影响。”

The company’s business model is to operate as a contract manufacturer with its systems and qualify customer applications through its区域打印Production (APP) program. Through the APP program, Seurat validates material properties, process repeatability, and ensures that it can consistently produce applications within a high-volume manufacturing setting.

到目前为止,八家公司从事该应用程序,并在包括汽车,航空航天,能源和消费电子产品在内的各种行业中都活跃。Seurat已启动了第一个用于汽车申请的商业计划,据报道,直到第3季度2022年就被预订。

“While scaling metal additive manufacturing to outcompete casting is very exciting for our industry, even more exciting is the prospect of winning back jobs, rebuilding trade skills, and enabling localized manufacturing – all in a sustainable way,” DeMuth says.

“If Seurat is successful – and it will take an ecosystem of inventors and policymakers to help us – the economic and environmental implications will change our future generations.”

Powered by green energy

Seurat is building its first print depot in Wilmington, Massachusetts, which DeMuth believes will be a “seismic step” forward. The factory, which will 3D print critical parts for airplanes, cars, and “just about anything else”, will be 100 percent driven by wind and solar power, delivered through the Reading Municipal Light Department’s newRenewable Choice program.

“I realized early on that manufacturing is closely tied to energy,” DeMuth offers. “Clean energy will be more affordable once we find a way to manufacture that is cost-competitive with existing technologies. With the IPCC recently calling out the catastrophic impacts of climate change, now is the time for a change.”

除了其印刷仓库外,Seurat还旨在使其未来的位置完全由可再生能源提供动力,以便其客户可以从金属3D打印中获得好处,同时消除DeMuth所谓的“肮脏的制造”的排放。

He says that Seurat’s switch to 100 percent green energy was a proactive move, and the firm is calling on its counterparts to follow suit. “Together,” he says, “we can make a significant difference a build a cleaner energy future.”

到2030年,该公司希望通过在美国通过区域印刷制造银器比使用海外发射碳发射工艺更负担得起。该公司还声称,其未来一代的机器的速度将比上一台机器快10倍,并旨在与可再生能源发电厂共同设置,或者进入合资企业,以在其缩放印刷品时采购自己的绿色能源仓库。

订阅3D Printing Industry newsletter有关增材制造中的最新消息。您也可以通过关注我们来保持联系推特and liking us onFacebook.

Looking for a career in additive manufacturing? Visit3D Printing Jobs在行业中选择一系列角色。

Subscribe to ourYouTube channelfor the latest 3D printing video shorts, reviews, and webinar replays.

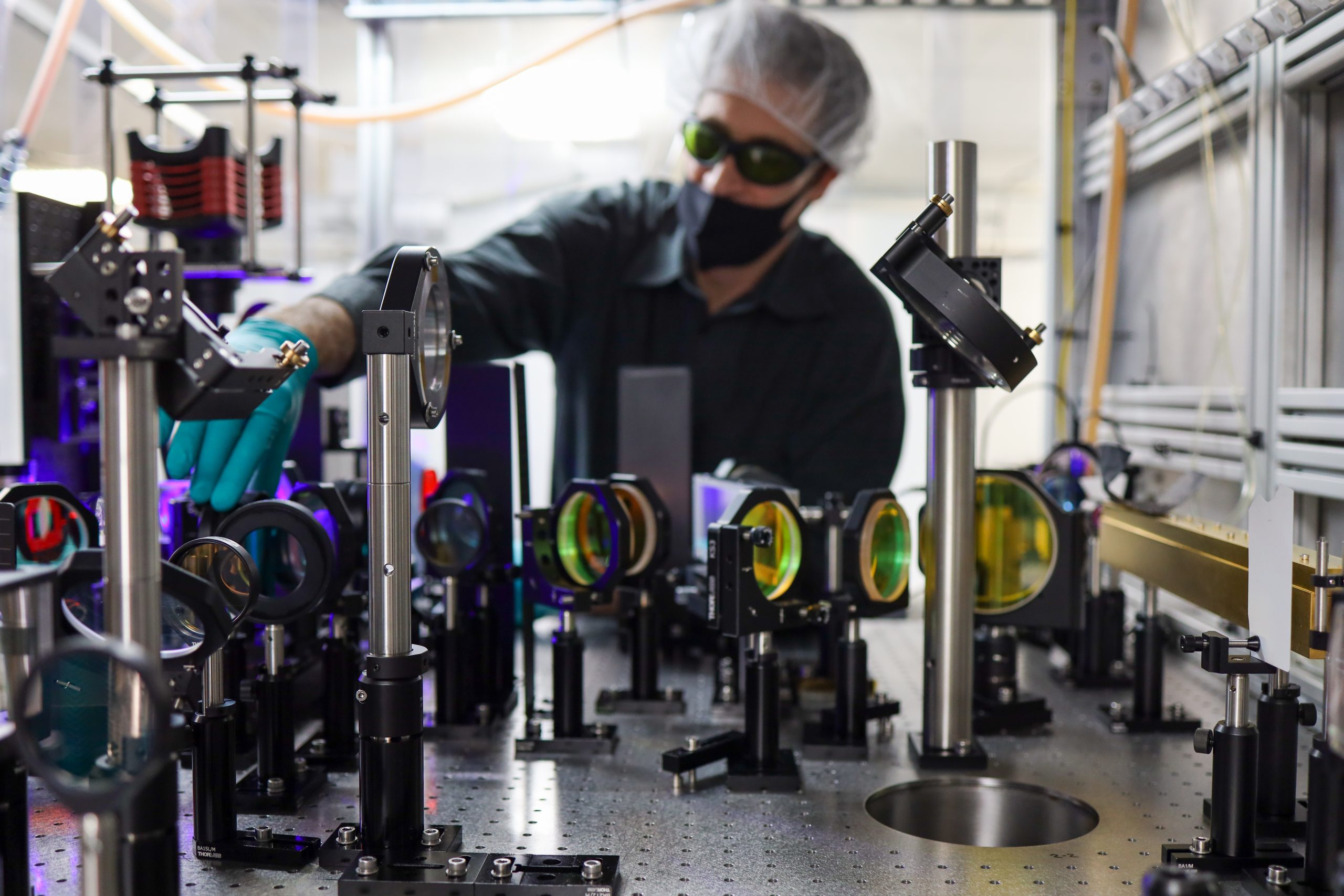

Featured image showsChief Scientist Andy Bayramian adjusts waveplate to complete optics upgrade on Seurat’s R&D system. Photo via Seurat Technologies.