来自美国和墨西哥的研究人员正在寻求更好地了解营养丰富的3D印刷食品的流变学和可打印性特征。

While 3D printed food products do make for the occasional playful headline, they also have serious potential to provide target populations with the specific nutrients they need. As such, one of the more promising reasons to advance food additive manufacturing is the prospect of personalized nutrition.

However, for individualized nutrition to cover a wide variety of needs based on a balanced diet, printing formulations composed of fruits, vegetables, grains, and perhaps even animal products are needed.

Custom food formulations with complex multi-ingredient mixtures have proven difficult to 3D print with extrusion-based methods in the past. This can largely be attributed to a lack of understanding of how food behaves during the printing process, so there’s an ongoing need to delve deeper into the effects of rheology on the printability of edible materials.

从橙皮到昆虫面粉

在本研究中,研究小组准备了多种营养印刷制剂,其中包含多达九种不同成分,包括可持续蛋白质,例如昆虫粉和橙皮等副产品。

With the ultimate aim of evaluating and correlating the rheological properties and printability of the formulations, the researchers varied parameters like the concentration of pregelatinized corn starch (4–10%) and printing temperature (27–47 °C).

通过振幅扫描,剪切效率测试,剪切恢复测试,时间依赖性剪切测试,温度升高和温度扫描,在流变学上进行了流变学表征。同样,通过对印刷结构的几何特征的数字图像分析来评估墨水的可打印性。

结果显示了什么?

Looking at the results, increasing the nozzle temperature of the 3D printer had the effect of reducing the stress at collapse values of the printed structures.

另一方面,将预脱染色的淀粉浓度从4%增加到10%大大提高了屈服应力,并且分别将印刷食品的储存模量从87.5 pa和1004.9和1004.9和2620.9 PA增加。但是,这些流变参数与改善的可打印性无关。实际上,可打印性评估表明,6%和8%的配方实际上表现出比10%墨水更好的可打印性。

最终,结果表明,在3D打印多晶状食品配方时,必须进行流变性和可打印性分析。较高的浓度并不表示出色的可打印性,尽管流变特性确实会影响材料特性,但它们并不总是准确地预测3D印刷结构在解体后的表现。

研究人员指出,将需要更多的研究来开发新技术以更好地评估3D印刷材料。尽管如此,该团队仍认为其工作可以作为未来研究的设计模板,以设计为添加剂制造的个性化营养墨水。

该研究的进一步详细信息可以在标题的论文中找到‘评估3D打印营养食品具有复杂配方的营养食品的评估”。

Although small, there is also an entire industry dedicated to food 3D printing technology. China-based 3D printer manufacturerWiiboox最近推出了它的new food 3D printing extruder。Named LuckyBot, the device can be integrated with a wide variety of standard desktop 3D printers to transform them into dedicated food printers. LuckyBot retails at $159 and is compatible with chocolate, peanut butter, cream, cheese, jam, mashed potatoes, salad dressings, and other soft foods.

Elsewhere, France-based food 3D printing firm数字糕点店announced the launch of its new糕点3D打印机,patiss3。据报道,受到3D打印技术的启发麻省理工学院,基于挤出的系统针对糕点厨师,餐馆和工业饼干工厂,使用户能够高速制造可食用的自由形状。

订阅3D打印行业通讯有关增材制造中的最新消息。您也可以通过关注我们来保持联系推特,喜欢我们Facebook, and tuning into the3D Printing Industry YouTube Channel。

寻找添加剂制造业的职业?访问3D Printing Jobsfor a selection of roles in the industry.

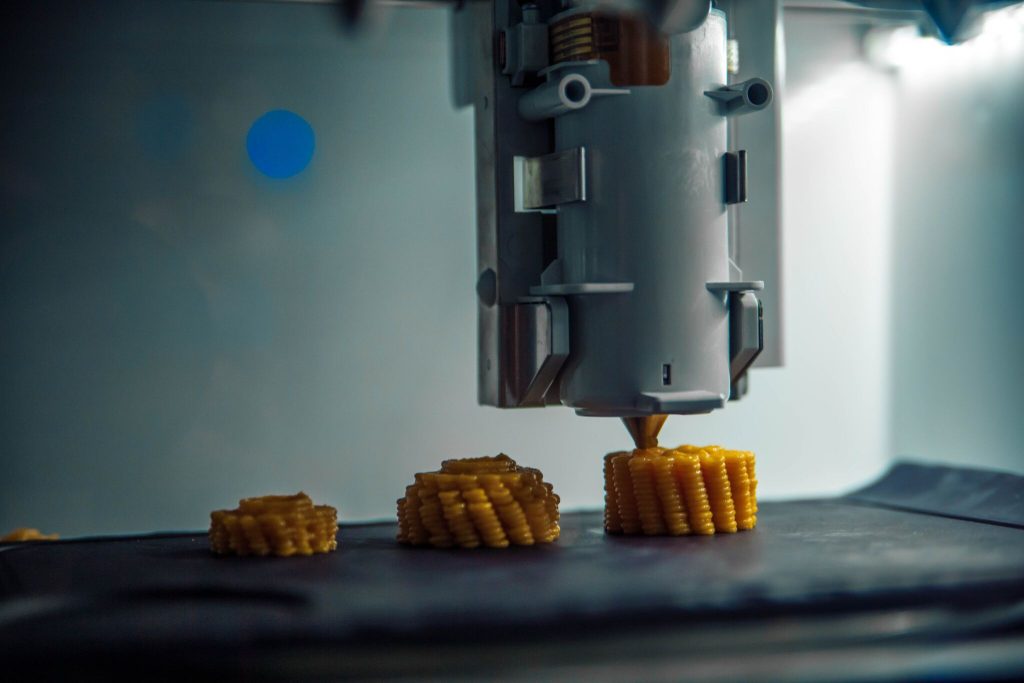

特色图像从食品机器中显示食物。通过天然机器的照片。