The超安全核公司(USNC)采用了两台3D打印机桌面金属最近更新的X系列粘合剂喷气系统。

能够打印诸如硅碳化物等先进材料的机器将是促进新一代高级核反应堆使用创新燃料设计的关键。

USNC核心部门执行副总裁Kurt Terrani博士说:“活页夹是一个低成本,高收益,可靠的过程。”“ X系机器的先进材料能力是我们创新的燃料设计方法的基础。”

USNC的增材制造采用

USNCis a global leader in the development of microreactors and nuclear power technologies, and has demonstrated a growing commitment to the adoption of 3D printing since the start of the year.

一月份,该公司宣布已许可的ORNL的新方法to 3D print components for nuclear reactors using Silicon Carbide and other refractory metals. The technology combines binder jet 3D printing with a chemical vapor infiltration process that enablescomplex reactor components to be fabricated比传统方法更有效。

就在上周,USNC透露plans to locate its pilot fuel manufacturing(PFM) operations at an 8.7-acre site situated in close proximity to ORNL in Oak Ridge, Tennessee, in a bid to ramp up the development of advanced nuclear fuel solutions, including the use of 3D printing. The plant is expected to be operational this summer and will see USNC and ORNL continue to work closely together on commercializing ORNL’s additive manufacturing technology and establish an advanced nuclear fuel supply chain.

Nuclear energy is one form of “clean” energy generation that is作为燃烧化石燃料的替代品,受到越来越多的关注根据Ornl教授Kathy McCarthy和Xin Sun的说法,3D印刷的核部件已经在该领域产生了影响。您可以了解有关3D印刷行业的采访系列的更多信息3D打印和可再生能源这里。

利用X系列

在2021年底,桌面金属将其粘合剂喷射投资组合与5.75亿美元收购Exone。作为收购的一部分,Exone的某些系统已被重塑为“ X系列”,即其Innoventx,X25Pro和X160Pro。

The X-Series is powered by ExOne’s patented Triple ACT advanced compaction technology for dispensing, spreading and compacting powders during the binder jet process. This enables a wide range of powders to be bound together and enables the printer to process metals and ceramics, such as silicon carbide, for the fabrication of functional, precision parts.

Silicon carbide is a technical ceramic material with excellent environmental stability that is often used in aerospace, armor, plasma shield, and high-temperature applications.

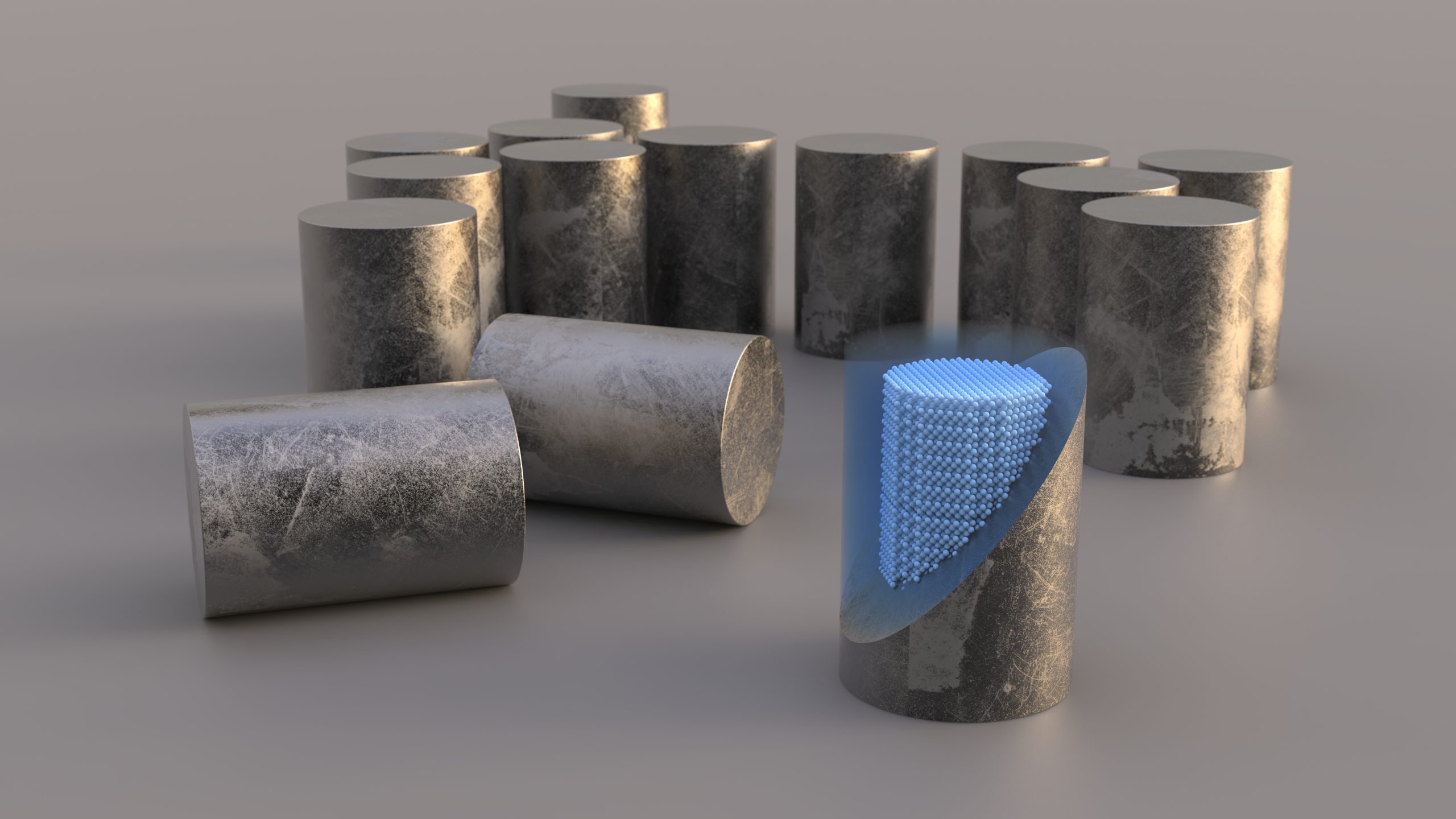

USNChas adopted two systems from the X-Series to enhance its capabilities in transforming nuclear silicon carbide into shapes that can safely surround a nuclear fuel particle, a key element of its Fully Ceramic Micro-encapsulated (FCM) fuel innovation technology. The approach is used to fuel USNC’s micro modular reactor (MMR) energy systems, which are known for their reliability and safety.

Terrani说:“超安全核正在核燃料和反应堆设计的出血边缘,开创了安全和性能方面的新进展。”“为新一代的微反应器供电代表了美国和全球零碳能源生产中的流域时刻。”

Explaining how the FCM and MMR systems work in tandem, Terrani added: “We’ve created a design for a passively safe reactor, so you don’t need a concrete dome, exclusion zone, or big water reservoir because it’s inherently safe. We’re leveraging a high-temperature resistant fuel with multiple inherent barriers to radiation release at the center of our reactor system. That’s the essence of the Ultra Safe Nuclear approach.”

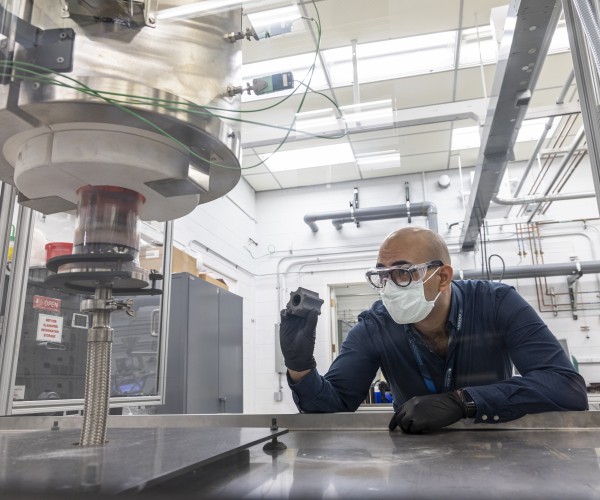

小型Innoventx已经安装在USNC位于犹他州盐湖城的工厂,该公司一直在努力扩大其在较大的X25Pro和X160Pro Systems上的下一代核燃料基质。

Terrani说:“那里有大量的增材制造方法,但其中很大一部分依赖于沉积过程中的高温过程。”“使用金属,它们正在熔化颗粒将它们连接在一起,但是您无法使用碳化硅的高熔点来做到这一点。活页夹技术之所以独特,是因为它确实依赖于功率的物理特性,并且基本上对材料的化学和相结构高度不可知。

“因此,我们可以选择高度纯净,高度结晶的碳化物原料粉,核等级粉末,然后形成这些非常复杂的几何形状,而这是不可能的。”

除了两个新的X系列系统外,USNC还将在今年晚些时候增加两台机器,以进一步扩展其核燃料设计功能。

“Driving mass adoption of additive manufacturing requires scalable systems capable of printing high-performance materials that enable the most innovative applications,” said Ric Fulop, Co-founder and CEO of Desktop Metal.

“我们很荣幸能够通过灵活的活页夹技术来支持USNC的使命,该技术将客户一路带入生产,并有助于在解决添加剂制造解决方案的全球规模问题中发挥作用。”

订阅3D打印行业newsletter有关增材制造中的最新消息。您也可以通过关注我们来保持联系Twitterand liking us onFacebook.

寻找添加剂制造业的职业?访问3D Printing Jobsfor a selection of roles in the industry.

Subscribe to ourYouTube频道有关最新的3D打印视频短裤,评论和网络研讨会重播。betway必威手机版登录

特色图片显示USNC完全陶瓷的微型封装燃料创新。通过桌面金属照片。