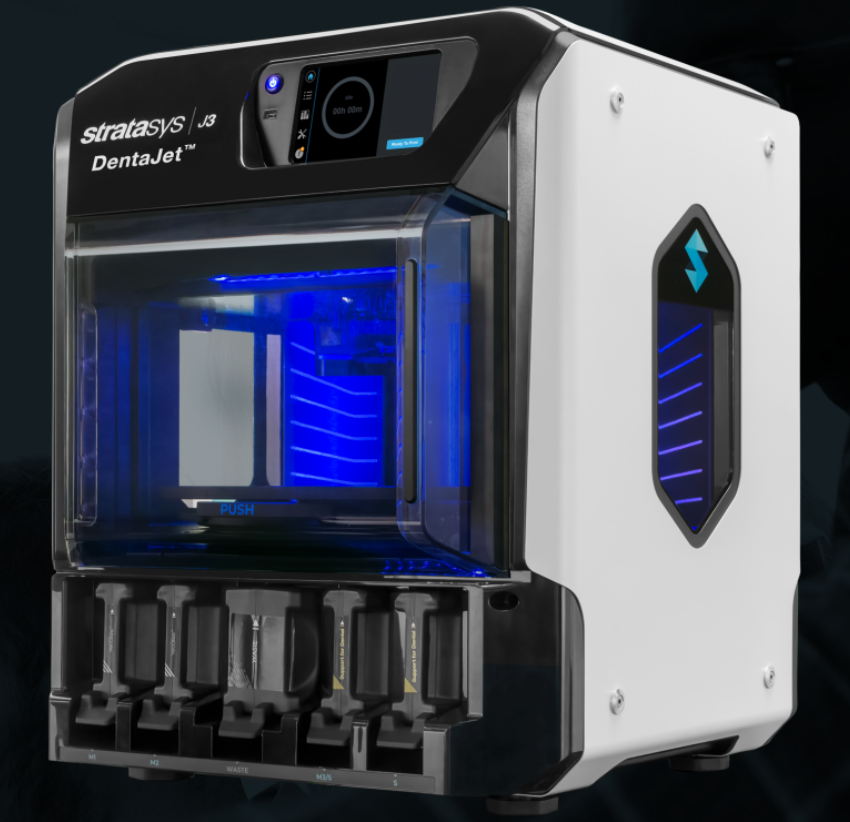

3D printer manufacturerStratasyshas introduced theJ3 DentaJet3D printer.

It is a beginner-level multi-material printer that allows dental labs to print highly precise mixed applications in a solitary tray at the same time. In addition, the J3 DentaJet will make its European debut at the forthcomingIDS global trade showin Cologne, Germany, from March 14 to 18. The novel printer will be displayed alongside Stratasys’ existing line of “renowned” dental solutions (Stand H051, Hall 10.2), such as theJ5 DentaJetandOrigin One Dental.

“这款打印机对于以前仅限于小型的单物质,桌面3D打印机的小型牙科实验室来说是一个很大的价值,并准备提高其牙科生产以提供高质量的数字牙科产品,” Ronen Lebi说。,Stratasys牙科副总裁。“添加J3 Dentajet 3D打印机可以帮助实验室生产一流的牙科应用程序,随着需求的增长,需要大规模准确性。”

Functionalities of the new J3 DentaJet 3D printer

The J3 DentaJet 3D printer uses biocompatible resins (clear, rigid, and flexible) to produce mixed components for implantology models (models, surgical guides, and gingiva masks), crown and bridge, and orthodontic models within a single print job. Its big circular build tray and “High-Speed” mode can assist labs in scaling and increasing output.PolyJet, Stratasys’ proprietary jetting technology, cures printed components during the printing process, reducing post-processing time. Consequently, lab personnel no longer have to deal with uncured resin, which improves workplace safety.

“We find PolyJet to be the best available technology for printing surgical guides, especially ones that require complex geometries such as stackable guides. Other technologies just can’t achieve the same level of precision and accuracy,” said Ilan Sapir, Manager, Digital Treatment Planner, at Glidewell Dental. “The J3 DentaJet enabled us to access the most advanced printing technology, packaged in a small footprint with a large print capacity.”

The J3 DentaJet is the latest addition to Stratasys’ line of dental-specific 3D printers, all of which can be controlled and managed usingGrabCAD Print, Stratasys’ user-friendly software for simplifying print preparation workflow. Stratasys is already taking orders for the printer, which will ship in March.

Technical specifications and pricing

| Model Materials | Biocompatible materials:• Biocompatible Clear MED610• VeroGlaze (MED620)• Flexible clear biocompatible materialMED625FLX 鲜艳的颜色包括:•Veromagentav(RGD852)•Verodent Purewhite(DEN847) |

| Digital Model Materials | Unlimited number of composite materials |

| Support Materials | SUP711™ (Waterjet removable) |

| 马克斯部分如果ze/Printing Area | 140 x 200 x 190mm (5.51 x 7.87 x 7.48 in.)Up to 1.174 cm2 |

| Layer Thickness | Horizontal build layers down to 18 microns (0.0007 in.) |

| Network Connectivity | LAN – TCP/IP |

| System Size and Weight | 651 x 661 x 774mm (25.63 x 26.02 x 30.48 in.); 98 kg (216 lbs.) |

| Operating Conditions | Temperature 18 – 25 °C (64 – 77 °F); relative humidity 30 – 70% (non-condensing) |

| 电源要求 | 100 – 240 VAC, 50 – 60 HZ, 10A, 1 phase |

| Regulatory Compliance | CE, FCC, EAC |

| Software | GrabCAD Print |

| Build Modes | High-Quality Speed (HQS) – 18.75μmHigh-Quality High Speed (HQHS) – 20.625μmLong Print Mode – 18.75μm (allowing cartridge Hot Swap for selected material) |

What does thefuture of 3D printingfor the next ten years hold?

Whatengineering challengeswill need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the3D Printing Industry newsletteror follow us onTwitter,或者像我们的页面Facebook.

While you’re here, why not subscribe to ourYoutubechannel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit3D Printing Jobsfor a selection of roles in the industry.

Feature image shows Stratasys J3 DentaJet 3D printer. Image via Stratasys.