Researchers from the伯明翰大学和南部昆士兰州大学正在探索使用Micro-3D打印技术来创建微针。

该方法利用一种称为两光子聚合的过程(2pp),这是一种高度专业的树脂3D打印的形式,特别擅长于在纳米范围内用分辨率制造复杂的微观结构。近年来,2pp在学术领域中蒸汽,并在微流体设备,光子学,微观镜和医疗设备(例如微针阵列)中应用。

跨国研究团队现已对2PP工艺进行了参数优化,专门用于开发具有复杂特征(例如侧通道)的聚合物微针。

沿着微针的纳米级

While conventional hypodermic needles are commonly used to extract blood samples and deliver compounds intravenously, microneedles and their miniaturized form factors have their own set of novel applications. This includes transdermal drug delivery across the skin barrier, withdrawal of tiny biosamples for diagnostics, and even cosmetic procedures.

Microneedles can be made of all manner of materials such as metals, silicon, glass, and even ceramics. Polymeric microneedles, in particular, are heralded for their biocompatibility and mechanical stability.

确实可以通过2PP打印聚合物变体,但是选择最佳打印参数以创建可用的微针阵列通常涉及广泛的测试。根据研究团队的说法,在打印参数优化方面的研究也有限,这使其成为艰巨的过程。

This isn’t to say it isn’t worth doing however, as scientists atStanford University和北卡罗来纳大学教堂山(UNC)最近3D打印了疫苗补丁他们声称比典型的疫苗相比提供了更大的保护。据报道,微针斑块直接应用于皮肤上,其免疫反应比输送到手臂肌肉的疫苗大十倍,同时无痛。

Elsewhere, at theUniversity of Kent和Strathclyde大学, researchers have previously developed a novel3D打印的微针设备,该设备使用微机电系统(MEMS) to closely control transdermal drug delivery. Named 3DMNMEMS, the device was developed with the goal of personalizing clinical treatment and allowing medical professionals to dose their patients based on their needs.

优化的微图过程

为了进行项目,团队利用Nanoscribe Photonic Professional GT3D打印机。该研究涉及打印许多具有不同工艺参数的微针测试样品,以识别最佳组合。最终,他们以80MW的激光功率定居,打印速度为50,000μm/s,切片距离为0.5µm至0.7µm。

Both the scan speed and the power of the laser were found to have significant impacts on the outcome of the builds, with faster scanning speeds resulting in lower levels (worse) of polymerization.

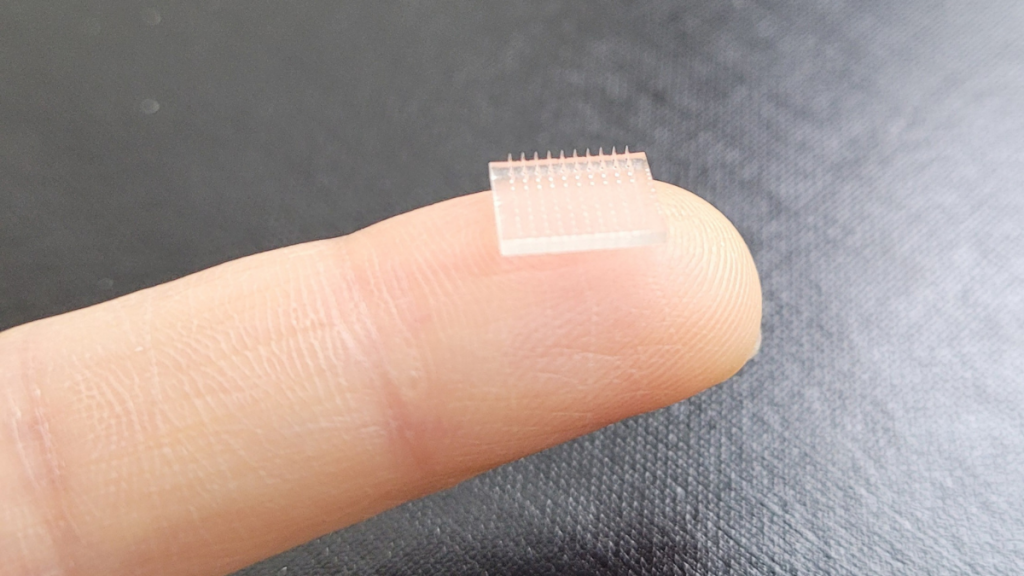

现在看着微针本身的几何形状,该团队发现,长高度为300µm的阵列在响应施加负载方面的性能最差。另一方面,仅150µm长的微针阵列可以承受突破之前的载荷高达50%。印刷零件还具有侧通道设计,该设计形成了横穿表皮的微流体通道。到达皮下区域,这些通道可用于输送药物并监测生物标志物。

In skin penetration tests performed on pig cadavers, the microneedles yielded great success while exhibiting no cytotoxicity or inflammatory effects.

最终,研究人员能够为聚合微针的优化3D打印过程开发,但断言该技术也可以用于其他高分辨率微观结构。

Further details of the study can be found in the paper titled“用于制造聚合微针的两光子直接激光写作过程的参数优化”。

Subscribe to the3D打印行业通讯for the latest news in additive manufacturing. You can also stay connected by following us on推特, liking us onFacebook, and tuning into the3D Printing Industry YouTube Channel。

Looking for a career in additive manufacturing? Visit3D打印作业在行业中选择一系列角色。

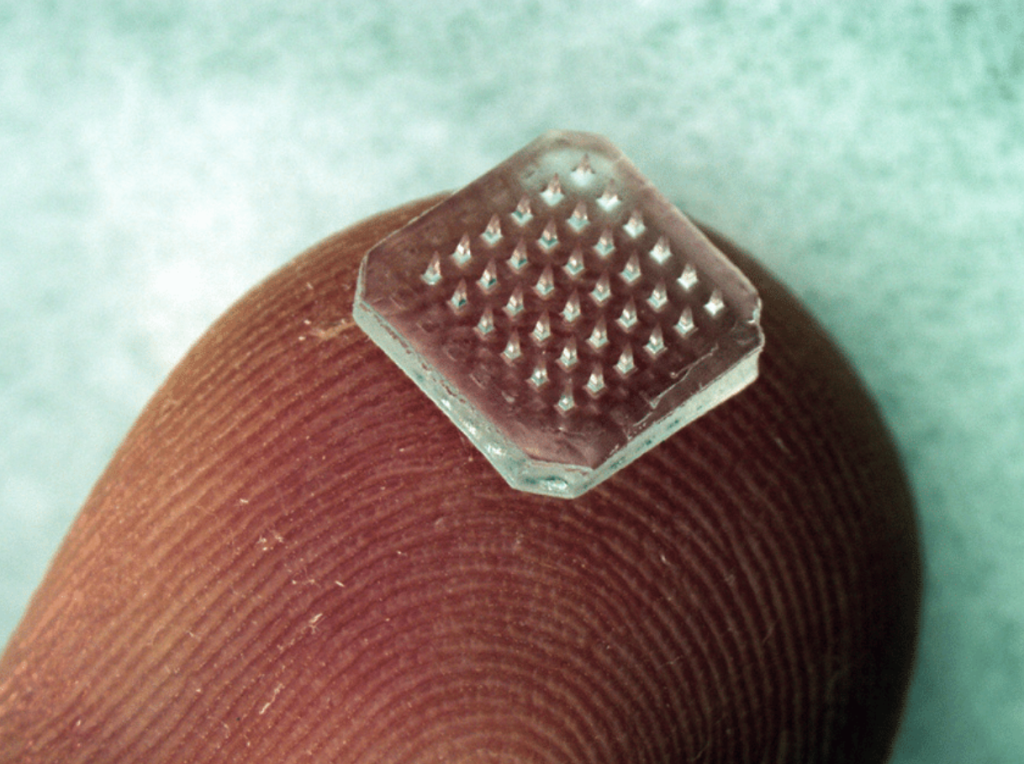

特色图像显示了常规微针贴片的示例。通过佐治亚理工学院的照片。