对于Rocket 3D印刷行业来说,这是一个重要的一周相对性空间和Launcher两者都宣布其航空航天计划取得重大进展。

相对性空间has revealed that it’s set to attempt its first launch of the 3D printedTerran 1火箭以嬉戏的好运,玩得开心或“ glhf”,现在预计会不会脱颖而出。与此同时,该公司赢得了170万美元美国太空力量合同有助于加速“ E-2”的研发,这是一种众所周知的火箭发动机,其具有3D打印的燃烧室和Turbopump。

“What we’re doing now is taking it to the next level, which is a long-duration test and the turbopump,” Max Haot, Founder and CEO of Launcher,告诉太空新闻在宣布合同的新闻发布会上。“我们也很兴奋,他们(美国太空部队)看到了分阶段燃烧引擎及其高性能的价值。”

将E-2通过其步调

自2017年成立以来,发射器已将其大部分努力用于开发其闭路电时高性能E-2液体火箭发动机。设计用于为公司提供动力发射器灯发射车将于2024年进入服务,推进系统将能够向低地轨道(LEO)发射高达150公斤的有效载荷。

到目前为止,在E-2的研发周期中,发射器发现3D打印其铜的零件是有益的,因为这释放了轻巧的机会,因此可以节省潜在的燃料。因此,该系统的许多组件都是通过该技术生产的,包括AMCM-3D打印燃烧室据说这是世界上同类产品中最大的一部分。

Launcher has also deployed additive manufacturing alongsideVelo3D和Ansysto improve the performance of theE-2火箭发动机的涡轮机, by fitting it with an upgraded impeller and housings. Through this iterative development process, the company has managed to make significant progress with the E-2, and itachieved full-thrust in hot-fire testing截至2022年4月,进行了40秒。

以前获得了$1.5 million US Space Force contractin 2019, to support the engine’s ongoing development, Launcher has now gained further backing from the same source. Awarded in the form of a SBIR Phase 2B tactical funding increase, or ‘TACFI,’ the additional funding is expected to be used to carry out longer-duration testing on both the E-2’s turbopump and combustion chamber.

Ultimately, Haot says the war in Ukraine has “made it clear that launch vehicles and access to space is strategic,” and his firm hasn’t “seen any slowdown” in demand from goverments, thus he sees a strong market for the E-2 once it’s ready.

启动Terran 1进行发射

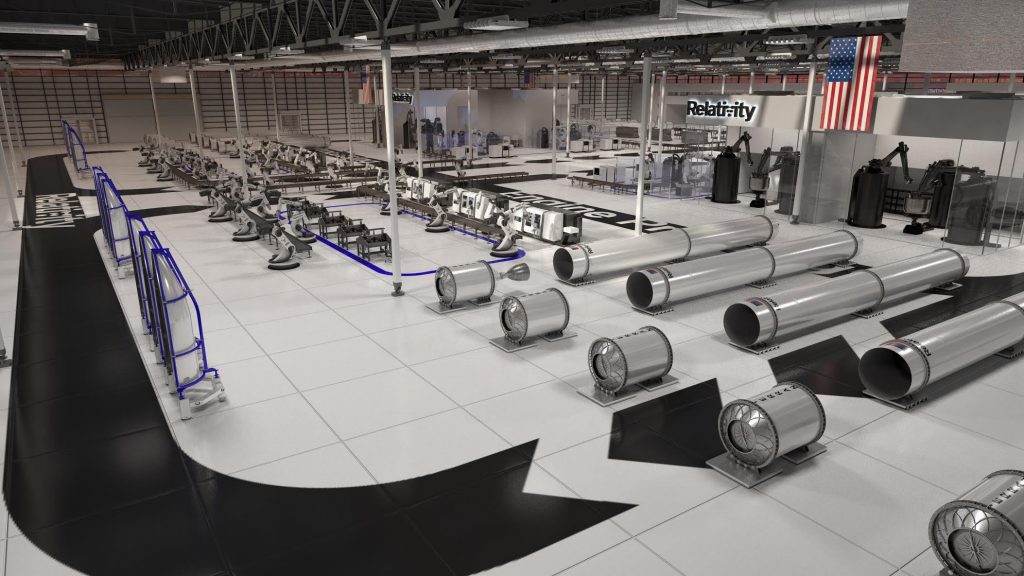

Not content with just 3D printing the engine of its Terran 1 rocket, Relativity Space has made the technology central to the launch vehicle’s production. Built using the automated, robotic arm-mountedStargate 3D printer, the Terran 1 is designed to carry heavier payloads of up to 1,250 kg into LEO, making it ideal for constellation launch and resupply missions.

The rocket’s additive manufactured parts, which are said to make up 85% of the total build, include its3D printed AEON engine这是由于通过星际之门解锁的合并,该系统本身仅具有100个组件。Terran 1的另一个令人印象深刻的方面在于它的14 foot-tall 3D printed fuel tank, a part that when created in 2017, was seen as a first step towards printing a full 90-foot rocket.

Since then, Relativity Space has gained significant backing to fund the Terran 1’s development, including the closure of a$650 million funding round去年,其总筹集到超过12亿美元。随着承包商越来越有信心火箭会按照预期的方式执行,公司也一直在awarded satellite launch deals,像Iridium Communications和电视.

Likewise,Lockheed Martinchose Relativity Space to facilitate anupcoming cryogenic testing mission早在2020年,该公司已获得300万美元NASA启动合同as well, in which the Terran 1 is set to be used to fire several small satellites into orbit.

尽管火箭的首次亮相发布已从“ 2021年末”推迟到“ 2022年夏季”,但现在似乎已经准备好起飞了。尽管尚未揭示其处女航班的日期,但据了解,Terran 1是从Cape Canaveral的发射综合大楼16发射的,这将在没有客户有效载荷的情况下进行,因为它代表了首次尝试。

满足火箭的天空需求

尽管经济环境继续证明对大型企业的挑战,但这似乎并没有损害对高级火箭相关技术的需求,随着全球军事紧张局势的加剧,推动了高度政府级别的需求。Aerojet Rocketdyne's例如,最近将3D打印的Scramjet引擎部署在一个高超音速导弹试验, 通过开展美国国防部身体。

在最近的事件中,Ursa Major已经发布了自己介绍自己的计划3D printed rocket engine,能够取代俄罗斯制造的RD-180和RD-181,它们不再可用于美国航空航天公司。“ Arroway”将采用几个合并的3D印刷零件,并提供200,000磅的推力,预计将促进卫星发射以及美国国家重要性的任务。

在整个池塘,英国,Orbex还公布了第一个全面的它的主要轨道空间火箭的原型. Built with the help ofSLM Solutions和EOS公司AMCM,据了解,这款19米长的发射车是由可再生生物丙烷助力的,它的排放量比煤油燃料的火箭少了90%。

要了解最新的3D印刷新闻,请不要忘记订阅3D打印行业newsletter或跟随我们推特或喜欢我们的页面Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to ourYouTube频道,包括讨论,汇报和3D打印进程的镜头。

Are you looking for a job in the additive manufacturing industry? Visit3D Printing Jobsfor a selection of roles in the industry.

特色图像节目发射器进行了对NASA Stennis太空中心的3D印刷E-2火箭发动机进行热火测试。通过发射器/John Kraus摄影的照片。