美国私人航空航天发射器成功completed another testing milestone for its 3D printed E-2 liquid rocket engine atNASA Stennis Space Center。

The firm’s rocket engine achieved nominal thrust, pressure, and oxidizer/fuel mixture ration for the first time, and was reportedly in “perfect condition” after 40 seconds of test firing.

现在,发射器将把注意力转移到5月的进一步测试中,将火箭的燃烧(C*)效率从90%提高到98%的目标。

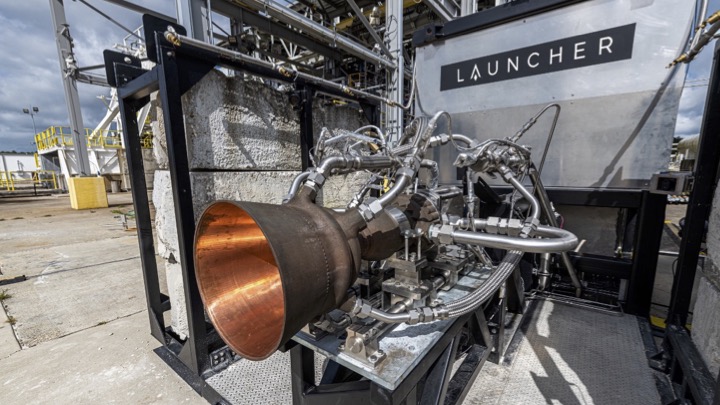

发射器的E-2火箭引擎

发射器成立于2017年是creati的目的ng efficient, cost-effective rockets capable of delivering small satellites to space. The firm began developing 3D printed components to enhance the performance of its E-2 engine after receiving a150万美元的美国太空部队合同在2019年。

The E-2 is a closed-cycle 3D printed high-performance liquid rocket engine that will power the firm’s Launcher Light launch vehicle, scheduled for launch in 2024. Once completed, a single E-2 engine will be capable of boosting the Launcher Light to low Earth orbit (LEO) with a 150kg payload.

到目前为止,该发动机包含多个3D打印组件,它们以高性能铜合金打印3D,以便需要较少的推进剂才能进入轨道。发动机由combustion chamber printed in a single piece据报道那是largest part of its kindat 860mm tall, and a 3D printed engine injector.

发射器与EOS组公司AMCMto develop a custom large-format 3D printer for produce its engine components, while its combustion chamber is produced using AMCM’s M4K machine. The firm conducted the第一次全尺度测试射击of its E-2 engine injector and combustion chamber in 2020, followed by a series of tests of its 3D printed liquid oxygen (LOX) turbopump, 3D printed on avelo3dSapphire printer.

In August last year, Launcher completed a成功推力室组件热火测试at NASA’s Stennis Space Center and a few months later purchased a second Sapphire 3D printing system from Velo3D capable of printing titanium, with which the firm will begin printing orbiter pressure vessels for the E-2.

Most recently, Launcher selected post-processing systems manufacturerSolukon就像它一样粉末去除系统的首选供应商。公司集成Solukon SFM-AT1000-S depowdering machine to post-process its 3D printed rocket parts and further automate its production process.

实现全力

发射器has now reached another testing milestone with its E-2 engine. The engine successfully demonstrated a full thrust of 10 metric tons during the test firing alongside achieving 100 bar of combustion pressure. The engine also saw the highest performance of oxidizer to fuel mixture ratio of 2.62 propellant mixture ratio for LOX at 100 bar of pressure.

After 40 seconds of total test firing time, the 3D printed copper alloy combustion chamber remained in “perfect” condition, demonstrating its reusability.

向前看,启动器将在5月初与同一室和喷油器再次测试E-2,尽管该组件将经过轻微的重新设计以删除所有胶片冷却以进一步提高性能。该公司的目标是将C*效率从最近的测试中的90%提高到98%,这是其最终目标。

The firm is also hoping to see its trademark blue Mach diamonds for the LOX/kerosene-based engine during the May tests, which it says would be a global first.

Regarding the development of its LOX turbopump, Launcher successfully tested the component in boost mode at 130 percent nominal flow. As a next step, the firm expects to demonstrate a full-duration, three-minute test of the turbopump in closed cycle configuration in Q4 2022.

最近的火箭测试成就

尽管发射器在其E-2火箭发动机的开发方面取得了重大进展,但该行业的其他参与者也在自己的引擎中进行重大流程。田野中的著名名称火箭实验室,,,,SpaceX,,,,Orbex,,,,andRelativity Spaceare all leveraging additive manufacturing as the race to space continues to ramp up, while several newcomers are also joining the contest.

In the last few months alone, propulsion system manufacturerAerojet Rocketdyne成功tested a scramjet systemas part of a US hypersonic missile research project. By 3D printing the engine’s drive system, the company says it can construct the component using 95 percent fewer parts than were needed to build its previous iteration.

在其他地方,太空技术3D打印公司X-Bow Launch Systemsexited stealth mode last month with alineup of small launch vehiclessuitable for both orbital and suborbital launches, while Chinese start-upSpaceTaiannounced plans for thefirst suborbital test flight明年将举行3D印刷火箭。

订阅3D打印行业通讯for the latest news in additive manufacturing. You can also stay connected by following us on推特并喜欢我们Facebook。

Looking for a career in additive manufacturing? Visit3D打印作业在行业中选择一系列角色。

订阅我们YouTube channel有关最新的3D打印视频短裤,评论和网络研讨会重播。betway必威手机版登录

Featured image shows发射器E-2thrust chamber assembly on its test stand at NASA Stennis Space Center. Photo via Launcher/John Kraus Photography.