捷克工业自动化专家冰工业服务has announced plans to begin using in-house-developed technology to begin rebuilding parts of war-torn Ukraine.

据说,该公司的系统由机器人的手臂或龙门架悬挂下来,由一种新型的混凝土销售打印头组成,据说该公司可以使3D打印具有独特的强大自然风格设计的结构。

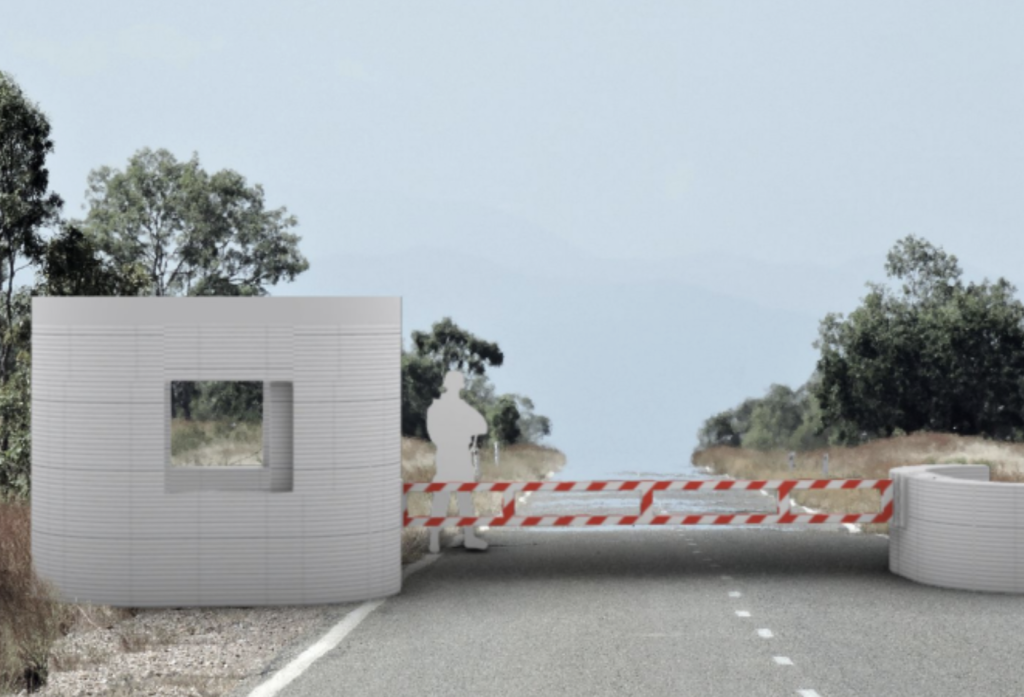

Speaking to 3D Printing Industry, the company’s CEO Tomáš Vránek has now revealed that it intends to deploy this technology to rebuild military barriers and checkpoints across the country, with the aim of protecting Ukrainian soldiers.

“What we were trying to achieve was to build the first 3D printed house in the Czech Republic, and with the situation in Ukraine, it just came as an opportunity,” explained Vránek. “We saw that they have sandbags everywhere and are hiding behind old cars, so we just thought, ‘let’s help them.’ Our architects and designers then came up with some shapes that should work to absorb bullet attacks.”

ICE的独特3D打印方法

Based in Prague, ICE Industrial Services is better known for designing, planning, engineering, building, and animating automated machinery, than it is for 3D printing. That being said, according to Vránek, the firm has recently begun to explore ways of “differentiating itself” due to both the impact of COVID-19, and the level of competition around supplying automotive clientele, which gets “quite nasty.”

With this in mind, ICE Industrial Services’ R&D department identified 400 areas of opportunity, before narrowing these down, with concrete 3D printing ultimately winning out. Aiming to modernize the house building process, something Vránek suggests is basically the “same as that used to build the pyramids,” the company has therefore opted to come up with its very own concrete printhead.

Packed with thirty different sensors, the device transmits data on the moisture, heat, warmth, and shape of layers to operators in real-time, as they’re printed. However, having accepted that ordinary concrete just wouldn’t be suited to construction 3D printing, the ICE Industrial Services team has also chosen to work with colleagues at theBrno University of Technology, to develop a custom material.

Much like the助剂促进混凝土created byCOBOD和Cemexlate last year, as well as图标的proprietaryLavacrete 3D printing material, the company’s concrete is considered, in the words of Vránek, part of the innovation that’s “hidden inside” the system, which makes it stand out against traditional competitors.

Vránek认为是USP的技术的另一个方面是其运营背后的专家团队。他与同事合作,首席执行官将其描述为一些“捷克共和国领先的参数设计专家”,他说,他的公司能够建立具有几何形状的自支持的辅助式辅助结构,这些结构确实利用了3D印刷的优势。”

“If you look at the house COBOD built in Germany, they just printed an ordinary squared house with right angles,” claimed Vránek. “This denies the advantages of 3D printing, which lets you print nice shapes that are inspired by nature and carry themselves.”

“Our biggest uniqueness lies in the real concrete we use and our team of architects, one of which has worked with Zaha Hadid, possibly the number one architect of the last few years.”

Answering Ukraine’s call for support

In light of the current situation in Ukraine, and having found that its technology is capable of creating buildings with patterned layers that make them highly resilient, ICE Industrial Services has recently begun to experiment with 3D printed barricades.

Specifically, by filling the gaps between walls with a combination of sand and tunable sandwich structures, the firm has found it possible to provide them with different degrees of reinforcement. While these structures are still undergoing ballistic testing, and Vránek admits they wouldn’t survive heavy artillery fire, he maintains that they’ve shown promise, particularly in resisting machine gun fire.

Vránek解释说:“他们主要提供防止步兵袭击的保护,如果有些火箭弹或坦克击中它,那么您就没有任何掩护的机会。”“我们甚至没有针对卡拉什尼科夫和冲锋枪进行测试,因为枪支不会做任何事情,因此我们取得了一些非常强劲的效果,主要是由于这种三明治结构。”

最近几周,ICE工业服务的实验开始吸引全球报道,甚至引起了乌克兰政府的注意。该公司与总理丹尼斯·希尔哈尔(Denys Shyhal)交换信件后,该公司已被邀请向州官员介绍其技术,以期将其用作重建在俄罗斯入侵中被摧毁的检查站的手段。

In the days to come, Vránek says the company plans to ship its first samples to Ukraine for research purposes, with the long-term aim of establishing a 20-system base there, and 3D printing on-site. Ultimately, Vránek adds that these could not only be used for military purposes, but even civilian ones, in the erection of “less demanding structures” that meet the immediate needs of Ukrainians.

Although ICE Industrial Services’ aspiration to apply construction 3D printing inside a conflict zone is fairly unique, it’s far from the first time the technology has been used to protect military personnel. ICON has previously worked with the德克萨斯军事部门to3D print training barracks,旨在在锻炼过程中容纳美军。

相似地,General Lattice已授予改善美国陆军头盔的影响using 3D printing and advanced lattice geometries. Through the ongoing research project, the firm aims to develop a predictive modeling toolset that helps it design and generate superior lattice materials for making military headgear.

远离建筑3D打印的世界,该技术经常被世界各地的武装部队部署在培训中,以实验其提供备件和维修的能力。这Australian ArmyhasSPEE3D实地测试的3 d打印机extensively in this area and reported carrying out at least one such exercise late last year, in the country’s remote Northern Territory.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the3D打印行业newsletter或跟随我们Twitter或喜欢我们的页面Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to ourYoutube频道,包括讨论,汇报和3D打印机评论。betway必威手机版登录

Are you looking for a job in the additive manufacturing industry? Visit3D Printing Jobsfor a selection of roles in the industry.

特色图片显示了ICE Industrial Services 3D打印机路障的模型。通过ICE工业服务图像。