3Deus Dynamics, a developer of 3D printed silicone medical devices, is developing a new hybrid process that combines 3D printing and injection molding to produce anatomical models for the medical sector.

CalledDynamic Molding,该过程最初是由公司的创始人在3D.FAB平台上开发的Lyon 1 University, and is the subject of two patents. As part of its development under 3Deus Dynamics, the technology has now been successfully deployed to create a life-sized patient-specific 3D model of a complex arterial disease for use in the planning and simulation of complex vascular surgeries.

3D打印解剖模型

Producing realistic and accurate representations of the morphology of the human body is对解剖学知识的教学至关重要, and this is where the benefits of 3D printing technologies can play a key role.

几年来,3D打印一直被利用以产生精确的,特定于患者的3D printed anatomical models和higher degrees of color fidelitythat cansave several hours in surgical planning time。因此,作为增材制造技术成熟,越来越多的3D打印公司是gaining ISO certificationandFDA清除对于他们的3D打印型号。

结果,Part Parter 3D打印的解剖建模服务变得越来越流行,像Stratasysand利科美国partnering todeliver 3D printed models到医疗机构,以及Fast RadiusandAxial3D提供一个new ‘DICOM-to-Print’ service对于美国各地的医院。

动态成型打印过程

3Deus Dynamics was established in 2020 by Edwin-Joffrey Courtial, Christophe Marquette, and Julien Barthès, with the goal of developing a breakthrough printing technology for the production of class III silicone medical devices.

The firm’s multi-patented Dynamic Molding technology is a hybrid process that sits at the crossroads of 3D printing and injection molding. While the process is compatible with all common injectable materials, it is particularly suited to working with specialty silicones.

该过程通过使用流体有机硅和颗粒状材料(例如玻璃珠)来制造具有复杂几何特性的物体的流动性能。流体有机硅由浸入颗粒介质中的微剂量沉积,然后在印刷过程中形成动态模具以支撑材料。

The physical properties of the powder used supports the object during the printing phase and ‘self-repairs’ after each of the micro-doser’s movements. By overcoming gravity in this way, the process prevents the print from collapsing, which is a common problem when 3D printing flexible materials.

结果,动态成型能够产生复杂器官的耐用物理和复杂硅酮复制品,例如心脏,前列腺,脑,肾脏和肺。除了它们的耐用性外,模型还复制了天然人体组织的质地和弹性,并可以切割,缝合并注入支架和植入物而不会撕裂。

The method is also capable of producing structures of varying rigidity in order to model pathological structures such as tumors within an organ.

Treating arterial disorders

3Deus Dynamic的动态成型过程已成功利用,以产生患者特异性的3D印刷解剖模型,以帮助治疗复杂的动脉疾病,例如动脉瘤。产生组织和动脉病理的准确,现实的复制品,可以更好地理解和模拟手术程序以及特定患者所需的适当治疗方法。

动态成型过程是由法国第二大医院(Hospices de Lyon)选择的,以执行由血管外科医生Patrick Feugier领导的项目。IMVASC3D项目旨在生产一种复杂的动脉疾病的患者特异性3D模型,以通过微创手术来治疗。

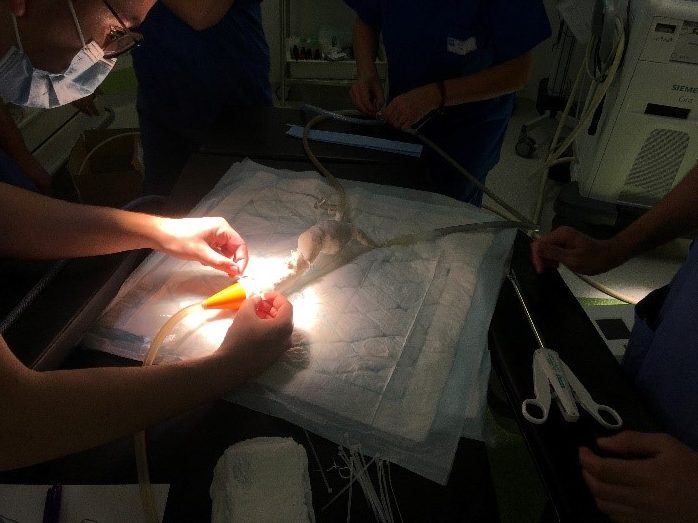

使用动态成型过程制造了真人大小的3D打印腹主动脉瘤模型,从数字STL文件开始,然后通过特定成像软件进行虚拟3D重建,以揭示患者的动脉树。根据3Deus Dynamic的说法,这一成就是“世界第一”,标志着复杂的硅胶解剖模型发展的重大进步。

3D模型包含一个空心,柔性且易于操纵的结构,并具有分辨的解剖学细节,例如乳糜泻,肾动脉,上肠系膜上动脉和动脉常见。Feugier和他的团队在导管插入条件下验证和评估了3D模型,以证明其在血管手术中复杂动脉手术的模拟和计划中使用的能力。

The Dynamic Molding process can also be extended to other flexible anatomical model projects for the management of pathologies requiring planning and personalized intervention.

订阅3D Printing Industry newsletter有关增材制造中的最新消息。您也可以通过关注我们来保持联系Twitterand liking us onFacebook.

寻找添加剂制造业的职业?访问3D Printing Jobsfor a selection of roles in the industry.

Subscribe to ourYouTube频道for the latest 3D printing video shorts, reviews, and webinar replays.

Featured image shows3 d印制主动脉模型被用于真正的电导率itions in the operating room. Photo via 3Deus Dynamics.