US 3D printer OEMCarbonhas announced the development of an experimental bioresorbable material with demonstrable biocompatibility in vivo.

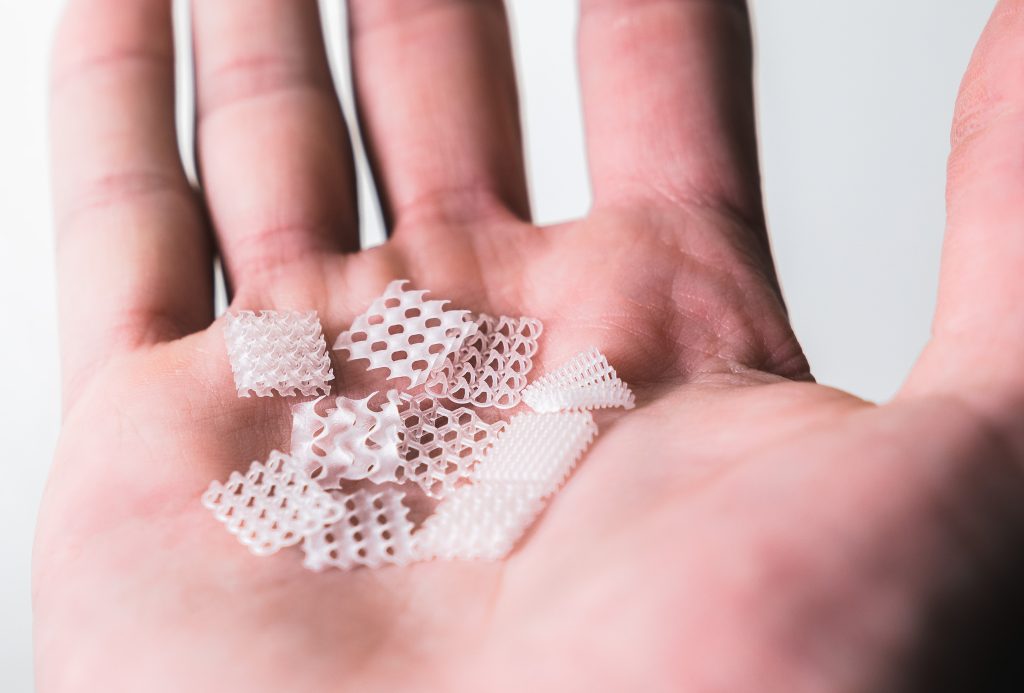

During testing, the in-house developed elastomer is said to have been designated ‘non-toxic,’ while being customizable to ensure that it’s fully absorbed into host tissues. As such, Carbon says the resin could be ideal for 3D printing lattices with applications in tissue repair, wound dressing or the creation of nerve conduits.

“我们非常高兴地宣布,碳的发育生物可吸收弹性体平台在体内表现出了生物相容性,” Carbon材料高级副总裁Jason Rolland说。“这些由碳数字光合成(DLS)技术制成的复杂结构可能是应对优化植入物的机械性能和降解速率的长期挑战的关键。”

“这是一个里程碑,我们期待与有兴趣的合作伙伴合作,进一步开发该树脂的应用程序。”

数字光合成技术

Based in Redwood City, California, Carbon’s 3D printing portfolio revolves around its proprietary DLS technology. In essence, the process involves using digital light projections and oxygen-permeable optics to cure photopolymer resins into 3D parts. Alongside DLS-equipped 3D printers, which are marketed via a subscription model, the firm also offers a range of engineering-grade materials.

This product lineup now includes resins that vary from the rigid, fatigue-resistantFPU 50, to the dental-focusedDPR 10,每个特征都使它们在某些用例中具有吸引力。EPU 40, for instance, offers high impact absorption, making it ideal for creating vibration-prone parts like gaskets, whileCE 221is said to be great for producing fluid routing parts with high thermal stability.

When it comes to medical materials, Carbon has previously dipped its toe in the water with resins likeMPU 100, which is biocompatible and sterilizable. However, the company’s offering lacks an elastomer that’s bioresorbable i.e. that can be absorbed into the human body, a trait that’s increasingly in demand from medical implant manufacturers, and it now aims to change this via its elastomeric R&D.

Carbon’s experimental elastomer

As it’s still under development, Carbon hasn’t yet named its experimental elastomer, but if the results of its latest testing are anything to go by, it could have significant potential in the healthcare sector. According to the firm, its latest milestone study showed that the material offers “impressive mechanical performance, biocompatibility and tunability.”

This could be particularly important when it comes to tailoring the resin’s absorption rate to meet different clinical applications. With the elastomer having also shown the required tissue tolerance and desirable healing responses for an implantable device through 26 weeks, Carbon now believes it has the potential to address a whole host of use cases.

When dressing wounds or repairing tissues like tendons, biomedical grafts are often used to reduce inflammation and accelerate healing. Given its resin’s enhanced elasticity and directionality, as well as its consistency of mechanical properties, Carbon believes it can address such applications in a way that limits any need for repeat operations, and allows patients to move more freely once treated.

In the production of artificial nerve conduits, the company also sees its material as having the qualities needed to provide enhanced flexibility, porosity, neuro inductivity and neuro conductivity. Post-surgery, meanwhile, the firm says its elastomer can be used to create absorbable lattice ‘cushions,’ which prevent bleeding or leakage from occurring in soft tissues as they move during healing.

Bioresorbable 3D printing advances

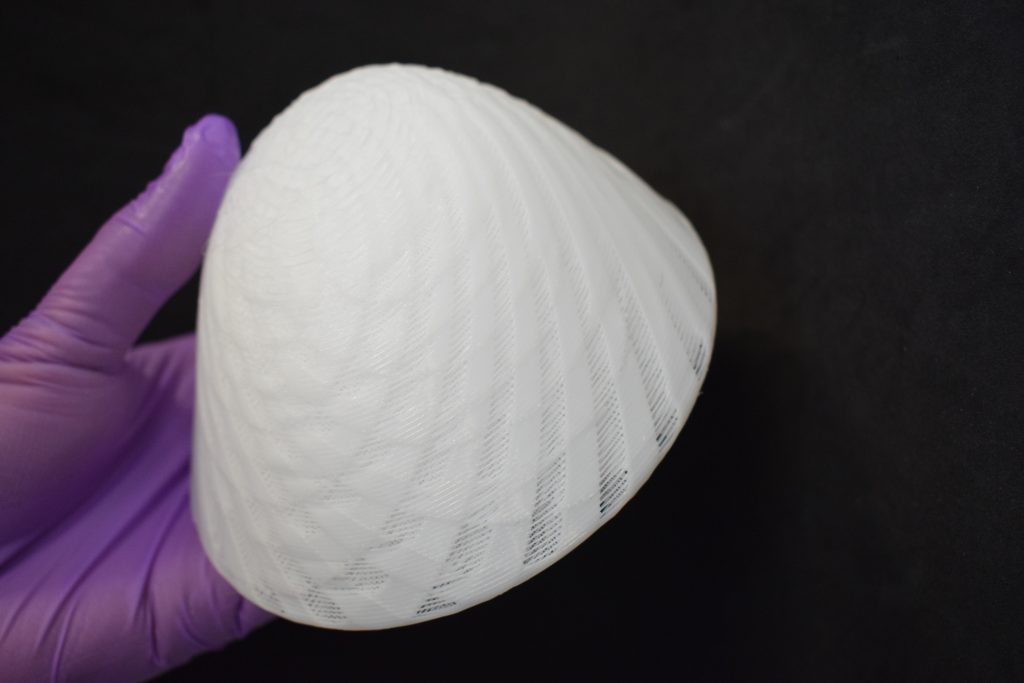

With 3D printed medical implants beginning to gain traction in certain parts of the healthcare industry, an increasing amount of R&D is being committed to making these bioresorbable.BellaSeno’s 3D printed breast scaffolds, which are designed for implantation during breast regeneration surgery, were used in human trials for the first time this year.

相似地,粒子3d已获得专利bioresorbable implant 3D printing material. Composed of ceramic suspended in a fatty acid matrix, the firm’s biomaterial enables the production of patient-specific grafts with ‘bone-like’ porosity.

在其他地方,较大的生物打印公司BICO已经开始与启动合作Nanochon发展3D printed regenerative joint implants. Nanochon says that once ready, the implants will deliver faster and more successful recovery rates for patients, while reducing the cost of treatment for healthcare providers.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the3D Printing Industry newsletteror follow us onTwitteror liking our page onFacebook.

While you’re here, why not subscribe to ourYoutubechannel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit3D Printing Jobsfor a selection of roles in the industry.

特色图像显示了一组示威者零件3D,该零件是由Carbon的开发弹性体打印的。通过碳照片。