Students at Swiss boarding schoolAuf Dem Rosenberg研究所曾与丹麦设计工作室合作SAGA Space Architectsto 3D print a 23-foot-tall extraterrestrial learning space.

Built alongside 3D printing veteransIngersoll机床和theCamozzi Group,据说罗森伯格太空栖息地(RSH)是世界上同类产品中最高的聚合物。实际上,该结构旨在适合SpaceX的星际飞船火箭,被学生用作实验室来探索远离地球的生活如何影响福利和测试高级空间系统。

“At Rosenberg, infusing education with real-life context is at the heart of what we do, rather than focusing on pure academics alone,” said Bernhard Gademann, Director General of Rosenberg. “Our aim is to provide future leaders with early exposure to the question of advanced space exploration, allowing our students to approach and solve these complex questions from a collaborative and holistic point of view.”

SAGA Space Architects’ lunar expertise

The Swiss students have realized their ambition of building a deployable learning habitat thanks to their partnership with SAGA Space Architects. The studio specializes in creating futuristic living spaces for outer space deployment using what it calls ‘Terra-Tech.’ This approach sees the firm combine topology optimization, generative design, and 3D printing to build nature-inspired structures.

To date, SAGA Space Architects has leveraged Terra-Tech to realize everything from office spaces and houses to the aforementioned space habitats. The second of these, the ‘罗西,’ features an outer shell that was 3D printed alongside Ingersoll Machine Tools, which has a history of using the technology in large-format applications. In fact, the company is currently working with the美国海军构建世界上最大的金属3D打印机,该设置用于构建整体船体。

The design studio is also part of the newly-formed3DCP Group与之合作COBOD构造Denmark’s first concrete 3D printed home。As well as committing to build the 37 square-meter house in Holstebro, the company has continued refining how it uses 3D printing to create architecture and working with students at Rosenberg, it has now returned to the field of space habitats.

Learning to live away from Earth

Unveiled on July 20, 2022, 53 years after humankind first landed on the Moon, the RSH is designed to enable the next generation to learn about the harsh realities of living and working in outer space. The project began over two years ago when Rosenberg students helped SAGA Space Architects troubleshoot issues around its ‘LUNARK,’ an experimental lunar habitat it deployed in Greenland.

Inspired by this experience, the team then started coming up with designs for a house that their residentBoston Dynamics- 建造的机器人点可以生活。从这些最初的概念来看,这个想法逐渐发展成为一个完整的三层研究实验室。RSH的外壳是在米兰印刷的3D,其内部结构是在哥本哈根建造的,由Camozzi Group和Ingersoll机床。

According to the students, using polymer 3D printing in the build was “revolutionary,” as it provided them with greater versatility than concrete would have done. The team behind the RSH also integrated a UV stabilizer into their material mix. In doing so, they found it possible to make the feedstock flexible, durable, and recyclable in a way that enabled them to break it down and reprint it where needed.

该结构同时建造了两名机组人员,该结构将充当研究中心,学生可以在其中参与沉浸式学习模块,以促进创造性的解决问题的技能。在其三层楼中,第一个包括卫生,实验室研究和与ABB Robotics这样的合作伙伴合作的设施。第二和第三是用于其他工作,娱乐活动和睡眠的旨在。

In terms of testing, the RSH is expected to house experiments that explore human wellbeing and those focused on developing software and hardware, such as remote mission control systems. Residents of the facility will also carry out research on sensory stimulation in remote living environments and work with advanced technologies such as automated mechatronics and AI deep learning programs.

“The Rosenberg Space Habitat is state-of-the-art in analog space habitats. It was developed in record time from initial sketches to the final fully functioning habitat in just months,” said Sebastian Frederiksen, Founder of SAGA Space Architects. “This is a great example of how working with outer space is pushing the boundaries of technology and architecture here on Earth as well, as this is the tallest 3D printed plastic ‘house’ in the world.”

“这只是栖息地的开始,现在研究和教育开始了。希望我们能学到很多关于在月球上生活的知识。”

Circular regolith-based lunar habitats

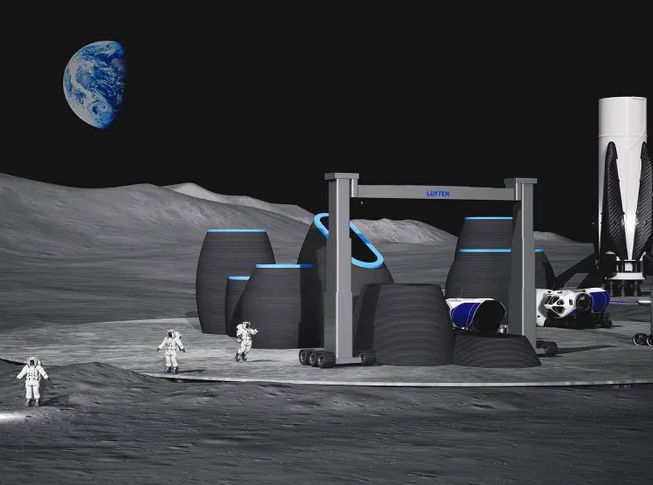

While the Rosenberg team’s project has seen them use 3D printing to build a largely polymeric space habitat, research elsewhere has often focused on using lunar regolith to build such structures instead. Engineers at theUniversity of New South Walesare working withLuytentoaccelerate the R&D of the Platypus Galacticas, a gantry-mounted 3D printer capable of building structures from lunar soil.

Scientists from theTechnical University of Braunschweig和Laser Zentrum Hannover(LZH), on the other hand, have3D打印的月球雷果在零重力下首次。作为实验性月亮项目的一部分,该团队在使用它融化Moondust成形之前,已将其定制激光器安装到其“ Mira3d”月球漫游器上。

More recently,NASA’s Kennedy Space Center和AI SpaceFactoryhave also unveiled designs for the3D printed ‘LINA’ lunar outpost。该设施旨在由Regolith-Polymer复合材料建造,旨在充当持久的结构,能够支持长期居住和未来前往其他行星的旅行。

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the3D打印行业newsletter或跟随我们Twitter或喜欢我们的页面Facebook。

For a deeper dive into additive manufacturing, you can now subscribe to ourYoutubechannel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit3D Printing Jobsfor a selection of roles in the industry.

Featured image shows the Rosenberg Space Habitat installed at Institut auf dem Rosenberg’s experimental ‘Future Park.’ Image via Institut auf dem Rosenberg.