在2022年的第二天国际制造技术展(IMTS), it became clear that ‘digitization’ and ‘automation,’ which have long been 3D printing buzzwords, are increasingly being reflected in reality across the industry.

在IMT第二天开始时,Canon销售工程师格兰特·扎霍斯基(Grant Zahorsky)主持了一次会议,他概述了自动化如何帮助制造商克服员工短缺。可以说,这为活动的基调定下了基调,整个Showfloor的公司都会发布有关产品的重大更新,并有可能最大程度地减少人类发明,同时优化零件的成本,交货时间和几何形状。

为了帮助制造商跟踪这一转变对他们的意义,3D印刷行业的Paul Hanaphy在芝加哥的现场活动中度过了一天,并将下面的IMT的最新摘要汇总在一起。

Varying advances in automation

At IMTS, a plethora of technologies have been displayed that are designed to help advance the automation of 3D printing, but these have also taken on vastly-different forms. At a Siemens session, for instance, Additive Manufacturing Business Manager Tim Bell said “there’s no better technology” to advance digitization in the world of manufacturing, than 3D printing.

However, for Siemens, this means digitizing factory design, as well as using the technology at sister firm西门子的流动性要数字化900多个单独的火车备件,现在可以按需打印。为了继续“加速3D印刷的工业化”,贝尔说,该公司已投资于在德国,中国,新加坡和美国开业的“捕捞”创新空间。

Ben Schrauwen,总经理3D系统- 拥有的软件开发人员Oqton同时,告诉3D打印行业,其机器学习(ML)驱动的技术如何促进更大的自动化部分设计和制造。使用一系列不同的ML模型,该公司的技术以优化构建结果的方式自动生成机器和CAD编程设置。

According to Schrauwen, one of the key benefits of adopting Oqton’s offering is that it allows for the printing of metal parts on any machine with “16 degree-overhangs, without any changes.” Already, he says the technology is gaining traction in the medical and dental industries, with demand in the oil and gas, energy, automotive, defense and aerospace sectors expected to follow soon.

Schrauwen解释说:“在Oqton的核心方面,是一个具有完全连接的IoT平台的MES,因此我们知道生产环境中发生了什么。”“我们追随的第一个行业是牙科。现在,我们开始进入能源领域。因为我们在系统中有很多数据,因此生成自动认证报告变得容易,石油和天然气就是一个很好的例子。”

Velo3D and Optomec’s aerospace exploits

Velo3D经常以令人印象深刻的航空航天印刷来参加贸易展览,而在IMTS 2022年,它并没有失望。在公司的展位上,它展示了一个钛推进剂坦克,它设法使用其生产蓝宝石3D打印机为了Launcher,无需纳入任何内部支持。

Velo3D技术业务开发经理Matt Karesh解释说:“传统上,您将需要支持结构,并且必须删除它们。”“然后,您将从残留物中拥有一个非常粗糙的表面。删除本身的过程也将变得昂贵且复杂,您将遇到性能问题。”

在IMT之前,Velo3D宣布已有资格M300 Tool Steel为了the Sapphire, and it also debuted parts made from the alloy at its booth. Featuring a high level of strength and hardness, the metal is said to have attracted extensive interest from various automotive manufacturers considering printing it into diecast inserts, as well as others leaning towards using it for tooling or injection molding.

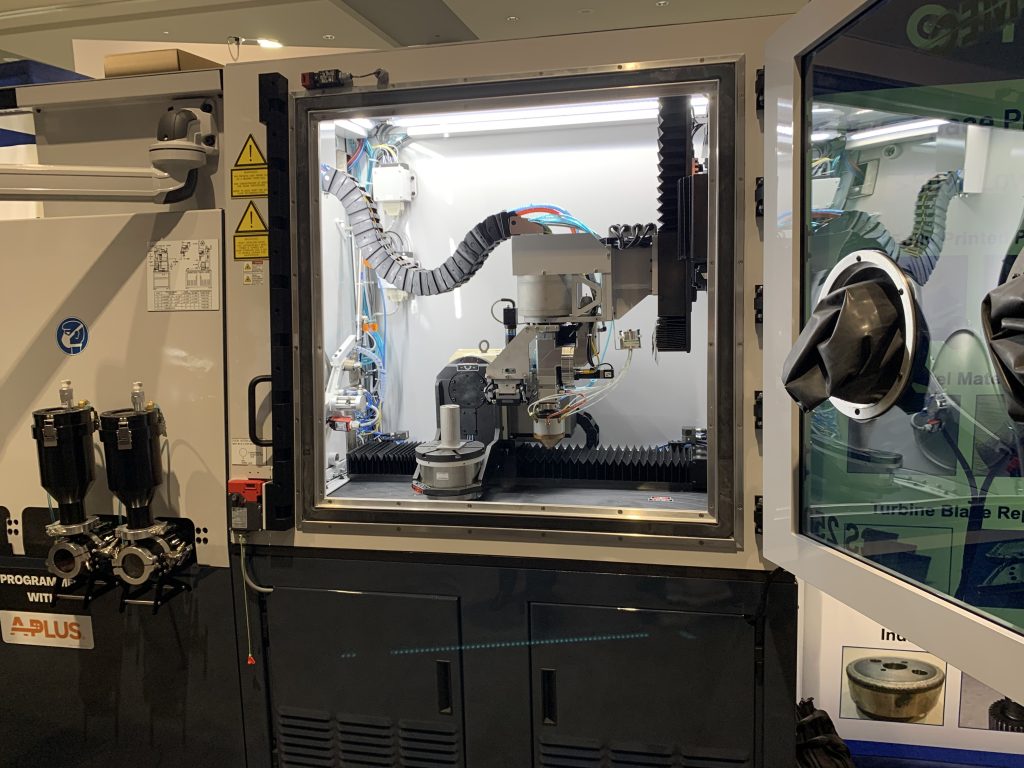

Elsewhere, in another aerospace-focused launch,Optomec推出了它与其一起开发的第一个系统霍夫曼子公司,LENS CS250 3D printer。The fully-automated manufacturing cell can be operated individually or chained together with others, to produce standalone parts or conduct repairs on builds like worn-down turbine blades.

Optomec区域销售经理Karen Manley通常设计用于维护维修和大修(MRO),但它解释说,它在物质资格中也具有巨大的潜力。鉴于该系统的四个材料喂食器可以独立喂食,她说:“您可以开发合金并打印它们而不是混合粉末”,甚至可以制作佩戴涂料。

Pushing high-throughput polymer AM

在光聚合物方面,两个进步确实很突出,其中第一个是P3偏转120的Stratasys子公司Origin的一台3D打印机。Origin的母公司与埃文克, the material is designed specifically for blow molding applications, in a process that requires parts to have a heat deflection of up to 120oC.

The material’s reliability has now been validated for this on the Origin One, with Evonik saying its tests suggest the polymer yields 10% stronger parts than those produced via a competing DLP printer, and Stratasys expects it to further broaden the appeal of a system with already-strong open-material credentials.

在机器进步中,Inkbit Vista 3D打印机也在展出的是,第一个系统被运送到圣戈巴恩。在节目中,Inkbit首席执行官Davide Marini解释了“该行业如何认为材料喷射是用于原型制作的”,但是他公司新机器的精确度,数量和可扩展性有效地反驳了这一点。

The machine enables the creation of multimaterial parts with meltable wax supports, and its build plate can be filled with a density of up to 42%, a figure Marini described as a “world record.” Thanks to its linear technology, he also suggested the system is flexible enough to one day be turned into a hybrid with ancillaries like robotic arms, although he adds this remains a “long-term” ambition.

Marini总结说:“我们正在闯入,并证明喷墨实际上是生产的最佳技术。”“目前,我们正在经历的最大牵引力是机器人技术领域。我们已经将机器运送到了一家机器人公司,该公司正在为仓库制作组件,您需要在这里存储商品和运输。”

要了解最新的3D印刷新闻,请不要忘记订阅3D打印行业newsletter或跟随我们推特或喜欢我们的页面Facebook。

While you’re here, why not subscribe to ourYouTube渠道?包括讨论,汇报,视频短裤和网络研讨会重播。

Are you looking for a job in the additive manufacturing industry? Visit3D Printing Jobs在行业中选择一系列角色。

Featured image shows the entrance to McCormick Place, Chicago during IMTS 2022. Photo by Paul Hanaphy.