Californian launch service providerRocket Labhas successfully fired a pioneering newNASAsatellite towards a ‘lunar orbit.’

Launched via the firm’s 3D printed engine-powered Electron rocket, the microwave-sized‘CAPSTONE’ CubeSatis designed to pave the way for humanity’s return to the Moon, as part ofNASA’s Artemis mission. Specifically, the device is set to become the first spacecraft to enter a Near Rectilinear Halo Orbit (NRHO), the planned trajectory of the网关outpostbeing built to support lunar excursions.

Rocket Lab创始人兼首席执行官Peter Beck说:“今天的发射是人类重返月球的重要一步,也证明了Capstone背后数百人的决心,决心和创新。”“ Rocket Lab的成立是为了开放空间的通道,并实现了这样的开创性任务,以推动小型卫星的可能性。”

“While CAPSTONE’s journey to the Moon has only just begun, we’re proud to have safely delivered CAPSTONE to space.”

火箭实验室的卢瑟福引擎

Having facilitated the launch of 147 satellites over the last sixteen years, Rocket Lab has established itself as a reliable partner for aerospace firms and space agencies alike. In large part, the company’s offering revolves around itsNeutron和Electronlaunch vehicles, which are powered by its Electron Beam Melting (EBM)3D打印的卢瑟福引擎.

现在已经了3D printed more than 100 times, the Rutherford is a liquid propellant fuelled carbon composite engine, capable of carrying a payload of up to 225 kilos and reaching a thrust of 120N, making it ideal for firing SmallSats into orbit.

自从the Electron’s first successful mission, Rocket Lab has been commissioned to launch several R&D satellites. In 2020, the companyfired a weather satellite into spaceas part of the空军研究实验室整体程序。今年早些时候,该公司也是selected to launch NASA’s ‘VADR’ payloads, in a $300 million project set up to help identify new opportunities for US aerospace businesses.

Paving the way for a lunar return

NASA的Cislunar自主定位系统技术操作和导航实验或“ Capstone”卫星已建造,以促进其Artemis任务。对于那些不熟悉的人来说,该计划的主要目标是自1972年以来首次将人类返回月球,并在天体的表面上建立一个基础。

In a bid to ramp up its preparations for the mission, NASA has regularly turned to additive manufacturing. During 2020, the agency developed3D printed nozzles and combustion chambersthat could be deployed in the program, shortly after working with a team atTuskegee Universityto test3D printed parts of the Artemis lander.

With its CAPSTONE launch on June 28, 2022, NASA’s latest adoption of 3D printing-enabled technologies has now seen it begin preparations for the deployment of Gateway, a space station designed to enable future lunar and martian exploration.

由__建造Tyvak纳米 - 卫星系统, the CubeSat will do so by trialing NRHO, an orbit that’ll see it pass as close as 3,000 km and as far as 70,000 km from the lunar surface, in a way that enables it to get caught between the Earth and Moon’s gravitational forces, and rotate in tandem with the latter, keeping it in position.

Having announced the CAPSTONE’s “flawless” launch via Rocket Lab’s Electron launch vehicle, NASA says it’s now in a stable orbit, ready to be propelled towards the Moon. From its initial orbit, the spacecraft bus onto which the CubeSat is affixed, is set to perform a series of orbit-raising maneuvers over five days, that’ll see it stretch its orbit into a prominent ellipse around Earth.

此阶段完成后,该设备将以24,500 mph的速度向月球发射,将其设置为预计需要四个月的弹道月球转移。在太阳的重力的帮助下,预计顶峰卫星将距离地球963,000英里,然后在沿着深空引力轮廓的弯曲轨道上拉向地球系统。

Those interested in following the CubeSat’s journey can do so viaNASA对太阳系的眼睛实时3D数据可视化工具,从启动后一周左右开始。

Driving satellite R&D with 3D printing

Of course, 3D printing isn’t just applied in the manufacture of the rockets used to fire satellites into orbit, it also continues to be deployed as a means of producing the devices themselves.Fleet Spacelaunched itspartially-3D printed Centauri 5 satelliteonboard aSpaceXFalcon 9 rocket earlier this month, complete with fully-printed metal patch antennas.

Recently,3D系统also announced that空中客车has contracted it to3D print “critical components” of the OneSat satellite. The device, which is designed to be fully-reconfigurable in-orbit, enabling it to change coverage area, capacity and frequency on the fly, is being built in-part using the firm’sDMP Factory 500.

Elsewhere, companies likeMitsubishi Electrichave even come up with a way offreeform 3D printing satellite antennas in-orbit. Using the firm’s technology, which revolves around a newly-developed liquid resin that’s capable photopolymerizing via the sun’s ultraviolet (UV) rays, it could be possible to manufacture parts larger than the satellite itself.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the3D Printing Industry newsletteror follow us onTwitteror liking our page onFacebook.

For a deeper dive into additive manufacturing, you can now subscribe to ourYoutubechannel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit3D Printing Jobsfor a selection of roles in the industry.

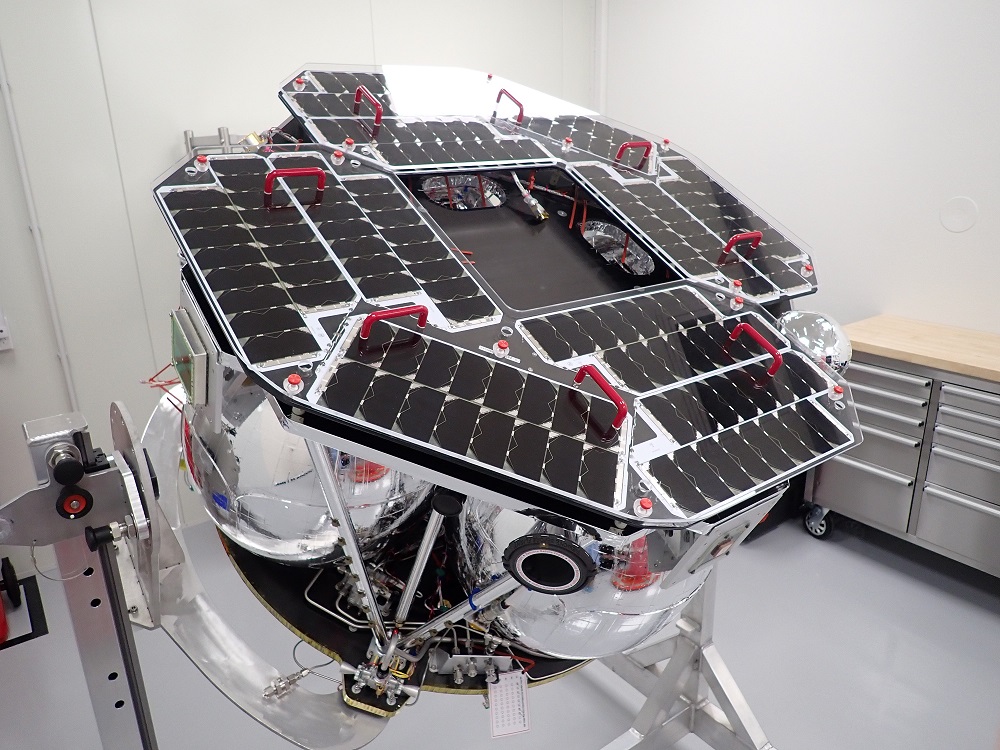

特色图片显示了电子火箭带有顶峰卫星。通过Rocket Lab的照片。