Russian state-owned industrial technology conglomerateRostechas received a license from the Russian Ministry of Industry and Trade to serially produce aerospace parts using additive manufacturing.

With the license, which据说ROSTEC允许为民用航空公司,直升机和发动机的组件生产和测试,已成为第一家确认其在为航空部门部署大众工业3D打印能力的俄罗斯公司。

Rostec的航空航天3D打印

Rostec’s Additive Technologies Center reportedly holds the largest fleet of 3D printing equipment in Russia, and has so far mastered the production of around 450 types of aerospace parts.

The center was introduced in 2018 after the firm为其开发分配了4450万美元。该中心以著名的发明家和氮化学专家,VV Chernyshev添加剂技术中心(CAC)的名字命名,并与俄罗斯航空公司的其他三名成员合作建立:Russian Helicopters, engineering firm技术科学学和无线电电子持有Kret。

At the time, Rostec’s Industrial Director of the cluster, Anatoly Serdyukov, said “industrial 3D printing is becoming one of the indispensable attributes of modern industry.” Russian Helicopters echoed this view, having致力于推进添加剂制造within its Ka series helicopter line.

The following year, Rostec’s subsidiaryRuselectronicsannounced it was developing an电子束金属3D打印机specifically geared towards aerospace applications.

许可串行生产

Rostec’s additive technologies center has now been awarded a license from the Russian Ministry of Industry and Trade for the mass production of 3D printed aircraft parts. The license enables Rostec to serially produce and test aerospace components for use in civil aviation applications such as aircraft, helicopters, and engines.

根据Rostec的说法,工业3D打印可以将某些航空航天组件的生产时间从六个月缩短到仅三个星期。该公司还观察到了体重的好处,其3D印刷零件比传统手段制造的零件要轻得多。

反过来,这允许增加有效载荷和飞机携带能力,同时还改善了其他各种飞机特征。Rostec已经开始为联合发动机公司开发的俄罗斯飞机发动机PD-14的Mass 3D打印零件。到2024年,该公司的增材技术中心预计将生产约2,000个发动机燃料系统。

JSC ATC总干事Vladislav Kochkurov说:“飞机大楼是最大的知识密集型行业之一,安全要求提高。”“许可证确认符合这些要求,并允许串联生产产品。

“这是增材技术和俄罗斯飞机行业发展的新重要阶段。”

Serial production for aerospace

While the aerospace sector has leveraged the efficiency, design and lightweighting benefits of 3D printing technologies for many years, the stringentsafety, regulation and performance requirementsof critical parts has meant that, in many cases, the technology has been slow to scale up to mass production levels for end-use parts.

Saying that, in August last year 3D printer manufacturerEOS,工业3D打印服务提供商Baltic3Dand MRO services providerEtihad Engineering宣布他们正在探索内部飞机零件的串行3D打印。研发项目将使用EOS的激光烧结技术看到波罗的海3D打印数千种材料样品,曾经通过该技术符合航空标准,将为飞机室内零件设计打印原型。

In-flight entertainment systems developerCabin Management Solutionsis also producing series of3D printed components for luxury aircraft, leveragingMarkforged的3D打印技术可创建符合FAA的零件。

Elsewhere, air distribution systems manufacturer高级航空航天BWThas installed two Stratasys Fortus 450mc 3D printers to3D print interior aircraft partsfor its customers in-house, while aerospace firmAirbus合格的3D打印服务提供商Materialise生产准备飞行的组件for its aircraft.

Subscribe to the3D打印行业通讯for the latest news in additive manufacturing. You can also stay connected by following us onTwitter并喜欢我们Facebook。

Looking for a career in additive manufacturing? Visit3D打印作业在行业中选择一系列角色。

订阅我们YouTube channelfor the latest 3D printing video shorts, reviews and webinar replays.

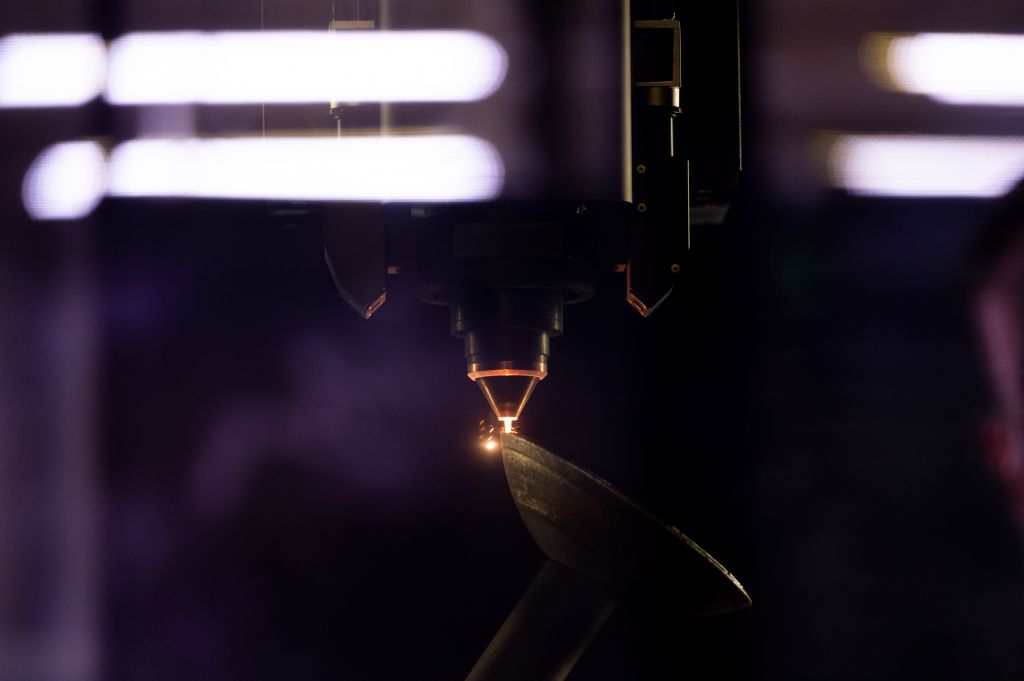

Featured image showsRostecis now licensed for 3D printing-based mass production for the aircraft industry. Photo via Alexander Utkin.