一支总部位于日本的研究人员正在调查选择性激光熔化(SLM)技术到由纯镍(NI)制成的3D打印单晶结构。

There’s been a growing demand for 3D printed Ni-based superalloys such as Inconel over the years. These high-temperature metals are often characterized by their excellent mechanical properties, corrosion resistance, and creep resistance, commonly operating in the 500°C+ temperature range. As such, they’re a go-to in the aerospace sector where they’re used to fabricate jet engine components like turbine blades.

单晶涡轮叶片能够在比晶体的高温下运行得更高,但是迄今为止,基于Ni的单晶超级合金的添加剂制造已经很难。尽管可以通过电子束熔化(EBM)处理它们,但使用基于激光的技术(例如SLM)通常需要使用单晶种子(构建板)。

现在,来自Japan’s National Institute for Materials Science,九州大学, 和大阪大学已经使用平顶激光轮廓到3D打印单晶Ni,而根本不需要种子。

Difficulties in controlling grain formation

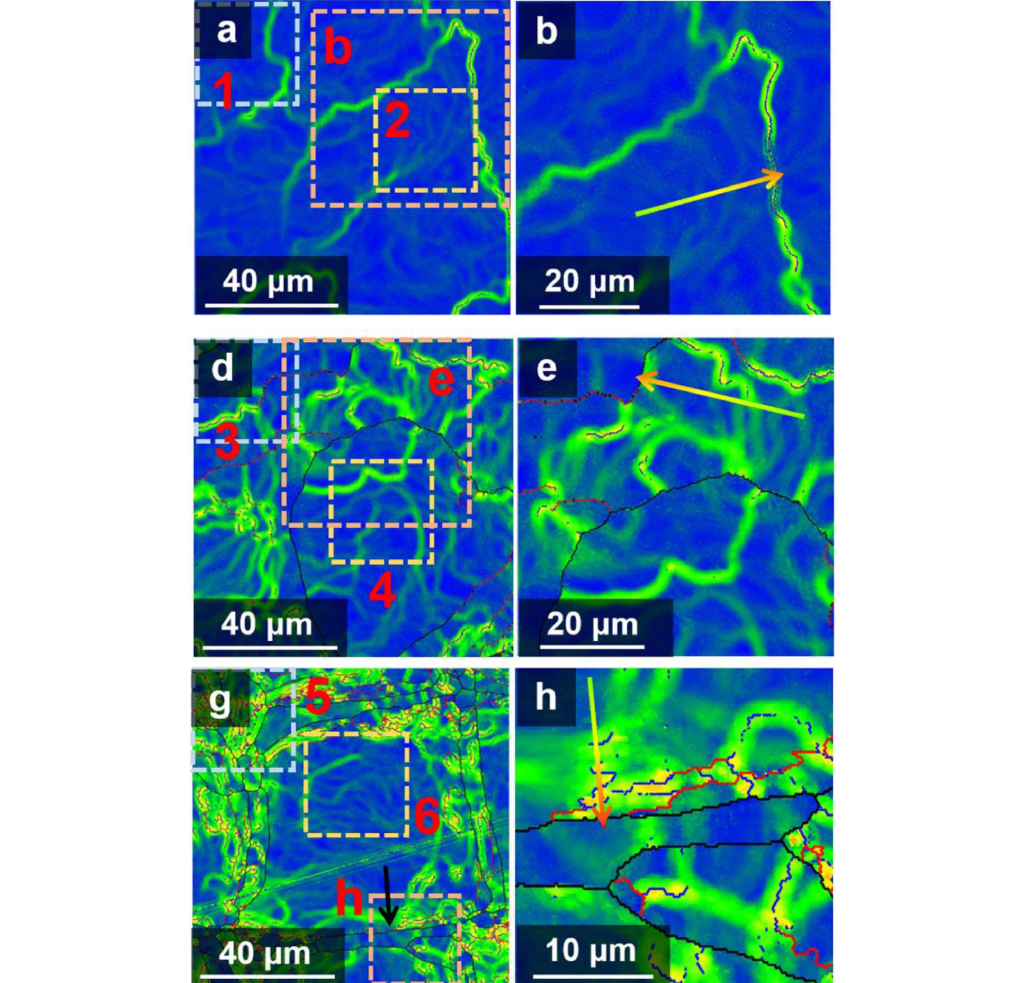

当用SLM打印时,密切控制晶粒边界,应变抑制和零件的质地同质性是一个棘手的过程。这可以归因于该技术固有的陡峭热梯度,因此顶层迅速加热,下面的层较冷,两者之间的热电导率有限。重复的热循环会导致高应变和脱位密度,从而导致内部动态结晶和新晶粒的形成。

For more precise microstructural control, especially to obtain single crystals, users either need to fine-tune the scan strategy or use a single crystal seed from the get-go.

根据研究人员的说法,基于高斯的光束曲线通常用于控制SLM中的纹理和微观结构,但目前尚无关注扁平束轮廓的研究。

3D打印同质单晶镍

In the present study, the Japan-based team used anSLM解决方案SLM 280 HL系统在AR环境中生产纯NI结构。首先,使用多晶Ni板检查单个平顶激光轨道的行为,这使团队能够估算后续熔体池的形状。

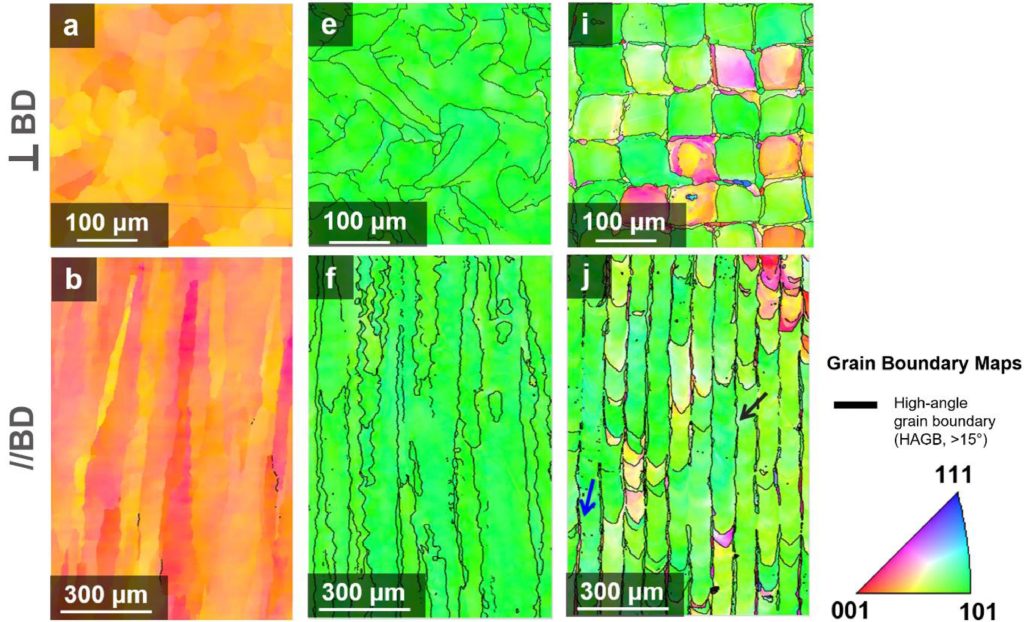

The melt pool depths were measured and the observed melt pool geometries were used to print cylindrical specimens made of Ni on polycrystalline stainless steel 304 build plates. Each of the specimens was ground and polished, and the microstructures were studied using scanning electron microscopy (SEM) imaging and electron backscatter diffraction (EBSD).

通过优化平面熔体池,该团队在3D打印纯净Ni的同质单晶结构方面取得了成功,而无需依靠单晶构建板。研究人员指出,这项工作提供了有关如何使用各种参数来控制微观结构及其相关特性的新见解,尤其是用于确保单晶结构。在未来的研究中,这些发现将通过更广泛的金属合金实施。

更多细节的研究可以发现paper titled“通过选择性激光融化使用平顶激光束制造纯镍的单晶”。

金属添加剂制造的世界丰富而多样化。一个团队Tsinghua大学and theNational University of Singapore最近调查了流体流对金属3D印刷零件机械性能的影响。尽管诸如温度梯度和凝固速度之类的因素得到了充分研究,但尚未研究3D印刷部分的熔体库中流体流动的影响。

在其他地方,一组国际研究人员最近深入研究了金属3D印刷背后的基本物理学,这一切都是为了希望更好地理解印刷零件中的缺陷。In critical industries where part performance is paramount, pores can pose a limitation on the types of parts that can be printed. As such, there’s an ongoing need to develop better defect detection and mitigation techniques in 3D printing.

订阅3D打印行业newsletterfor the latest news in additive manufacturing. You can also stay connected by following us on推特, liking us onFacebook,然后调查3D打印行业YouTube频道。

Looking for a career in additive manufacturing? Visit3D打印作业在行业中选择一系列角色。

特色图显示了IPF地图和扁平式3D打印标本的纹理。图像通过九州大学。