航天manufacturersGE Aviation和Safranhave announced the commencement of a demonstrator project focused on test-building a new open-bladed jet engine, and it’s set to feature metal 3D printed parts.

The news comes as the companies extend their joint venture,CFM国际, by ten years to 2050. Dubbed RISE (Revolutionary Innovation for Sustainable Engines), the environmentally-conscious engine is intended as a successor to the previously developed LEAP model, which is used on the波音737 MAX and someAirbusA320neo aircraft.

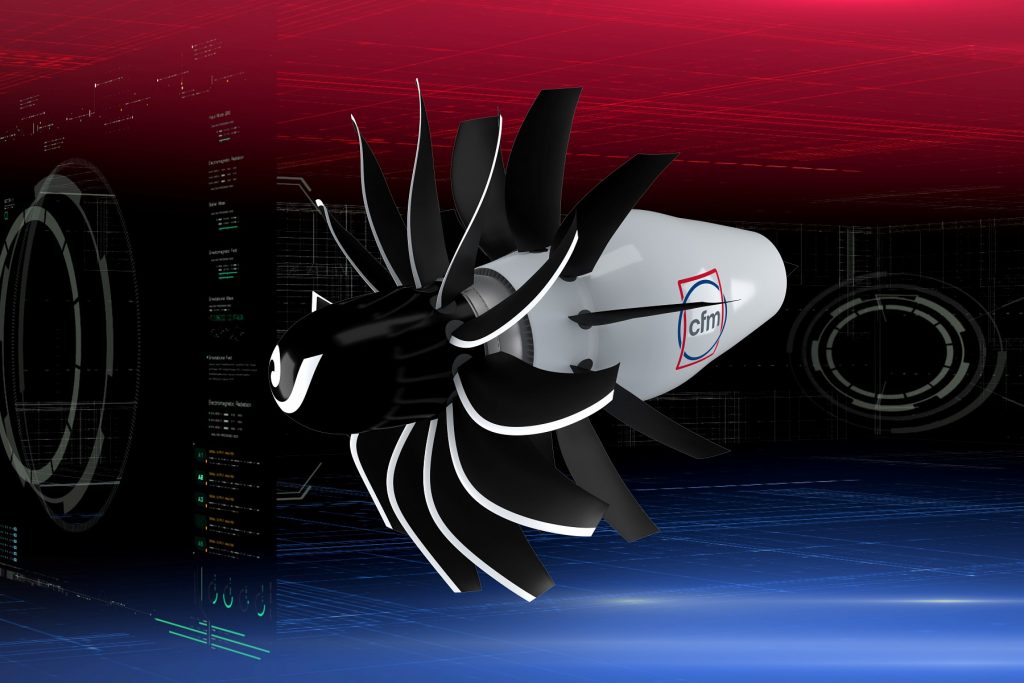

Interestingly, the new design is an open-rotor one, meaning the fan blades will be visible. With plans to commercially launch RISE by the mid-2030s, CFM claims the engine will be able to reduce fuel consumption and emissions by up to 20% when compared to its predecessors.

AGE添加剂发言人告诉3D印刷行业:“是的,金属3D打印将成为RISE计划的一部分。我们计划以多种方式使用添加剂制造。例如,多个涡轮机械组件将使用添加剂技术来支持复杂的几何形状。随着计划的发展,我们将分享更多细节。”

3D printing takes a LEAP

作为LEAP引擎的继任者,Rise Model将包含3D打印零件也就不足为奇了。自2016年以来的服务中,LEAP在航空领域中引起了浪潮,以设定新的燃油效率行业标准,并部分由GE的非凡3D印刷燃油喷嘴启用。

Leap嘴还具有比传统制造的同类产品轻25%和耐用性的五倍,还具有复杂的几何形状,该几何形状在喷气燃料被送入燃烧室之前将其预混合。每个Leap发动机都装有19种创新燃料喷嘴中的19个。GE从那以后3D printed hundreds of thousands of the component, marking a huge milestone for high-volume 3D printing in the aerospace sector.

“Unlike traditional combustors that mix fuel and air inside the combustion chamber, the LEAP nozzle pre-mixes these elements to provide what our engineers call lean burn combustion,” wrote the CFM International LEAP engine microsite. “We just call it revolutionary.”

The RISE engine

Building on LEAP’s success, RISE will offer hybrid-electric propulsion. The system will also be capable of running on 100% sustainable hydrogen, which is reportedly favored by Airbus when it comes to future concepts.

With an open-rotor form, the engine will no longer hide the turbine blades, which reportedly has the effect of capturing more air and reducing the aircraft’s reliance on the fuel burning core. On the other hand, aerospace firms have dabbled with the concept of an open-rotor airliner engine since the 1980s, but noise has historically been a major issue.

然而,根据赛峰集团首席执行官奥利维尔•安德利,the RISE engine is expected to produce about as much noise as the current LEAP model. Having tested a very early prototype in 2017, the firm is confident that the new design will meet “the most stringent noise regulations” and safety standards.

GE’s use of additive manufacturing doesn’t stop there, as the company’s GE9X engine also features over 300 3D printed parts. This includes铝制钛合金(Tial)涡轮3D printed using Arcam electron beam melting (EBM) technology. Back in 2020, the GE9X engines took to the air for the first time when Boeing completed thefirst flight of its 777X jet。

在其他地方,在可持续能源领域,GE Research最近被授予我们Department of Energy(DoE) to explore the design and manufacture of3D printed wind turbine blades。该项目最初将产生全尺寸的3D打印刀片尖端,用于结构测试,以及将三个刀片尖端安装在真实的风力涡轮机上。

Subscribe to the3D打印行业newsletterfor the latest news in additive manufacturing. You can also stay connected by following us on推特, liking us onFacebook,然后调查3D打印行业YouTube频道。

Looking for a career in additive manufacturing? Visit3D打印作业在行业中选择一系列角色。

Featured image shows a concept render for the new RISE jet engine. Image via CFM International.