For a deeper-dive into additive manufacturing, you can now subscribe to ourYoutubechannel, featuring discussion, de-briefs and shots of 3D printing in-action.

Aerospace propulsion system developerAgile Space Industrieshas announced the acquisition of 3D printing service bureauTronix3D.

By purchasing its long-term supplier and rebranding it ‘Agile Additive,’ Agile Space Industries aims to optimize the performance of the propulsion systems used to powerNASAandSpaceX’supcoming lunar missions, while ramping up its R&D of exotic 3D printed metal alloys.

“Having worked with Tronix3D as a supplier, we were continually impressed with their ability to develop new proprietary processes for working with very challenging materials,” said Jeffrey Max, CEO of Agile Space Industries. “We realized that if we integrated these competencies internally at Agile, it would further accelerate the innovation, quality and timeliness of the products that we deliver.”

The origins of Agile Additive

Founded in 2018 and based in Pennsylvania, what was Tronix3D and is now Agile Additive, essentially operates as a 3D printing service provider. Leveraging its installed base ofHPMulti Jet Fusion (MJF), SLA andEvatronixsystems, the company offers on-demand manufacturing, 3D scanning and post-processing services to clients in the medical, robotics and defense industries amongst others.

Under its Tronix3D moniker, the firm also provided customers with metal prototyping, pre-launch and manufacturing services via its Laser Metal Fusion (LMF) machines. The technology’s compatibility with ultra-conductive, corrosion-resistant steels and superalloys, often allowed Tronix3D to address the needs of military and aerospace clientele, including its new parent company.

While working with Agile Space Industries, the Tronix3D team repeatedly demonstrated the ability to apply its metal additive manufacturing expertise within the development of its customer’s next-gen rockets. As a result, Agile Space Industries has now opted to acquire its supplier, with the aim of building on its own intellectual property related to the 3D printing of exotic metal alloys.

“Parts that used to be complex or even impossible to manufacture are now achievable because of our advancements in 3D printing novel alloys,” said Buck Helfferich, President of Agile Additive. “For Agile Space Industries and the aerospace industry at large, our innovations across materials, unique build geometries, and in-situ print monitoring will allow us to deliver intricate and structurally sound parts.”

Delivering upgraded thrusters

Having conducted more than 6,000 hot-fire tests, Agile Space Industries has become a trusted propulsion system supplier to the likes ofRaytheon,Northrop GrummanandBoeingin recent years. The company provides everything from individual modules and tanks to full thrusters, which are built to launch CubeSats and upper-stage rockets into orbit.

However, since being contracted to supply thrusters forAstrobotic’s2023 NASA lunar mission, which will be conducted using a SpaceX rocket, Agile Space Industries has sought to extend its supply chain capabilities, and by purchasing Tronix3D, it anticipates being able to “drive faster delivery” and deliver “enhanced technical assurance” to clients.

Through its acquisition, Agile Space Industries also intends to develop its technologies in a way that allows spacecraft to be lighter and faster, thus being able to conduct longer-haul missions, although not at the expense of its subsidiary’s core business, as Agile Additive will continue to offer Direct Metal Laser Sintering (DMLS) services moving forwards.

AM-boosted rocket engines

As NASA continues to broaden the scope of its space missions, it’s increasingly turning to launch vehicles powered by rocket engines produced with the aid of additive manufacturing. Just last year, the space agency trialled3D printed rocket engine partsof its own, that could be deployed as part of its upcoming Artemis mission to return astronauts to the Moon.

NASA is also working closely withJohn Hopkins Universityscientists to investigate the use of 3D printing to manufacture asolar-powered interstellar rocket. Although still in the early stages of development, the novel hydrogen-powered propulsion system has the potential to accelerate research into the ‘heliopause,’ or the edge of the solar system.

Elsewhere, private aerospace firms such asAerojet Rocketdynehave made significant recent progress in their propulsion system R&D. The firm revealed in May 2021, that anupgraded RL10 rocket enginefeaturing a 3D printed injector and combustion chamber, had successfully passed NASA hot-fire testing.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the3D Printing Industry newsletteror follow us onTwitteror liking our page onFacebook.

Are you looking for a job in the additive manufacturing industry? Visit3D Printing Jobsfor a selection of roles in the industry.

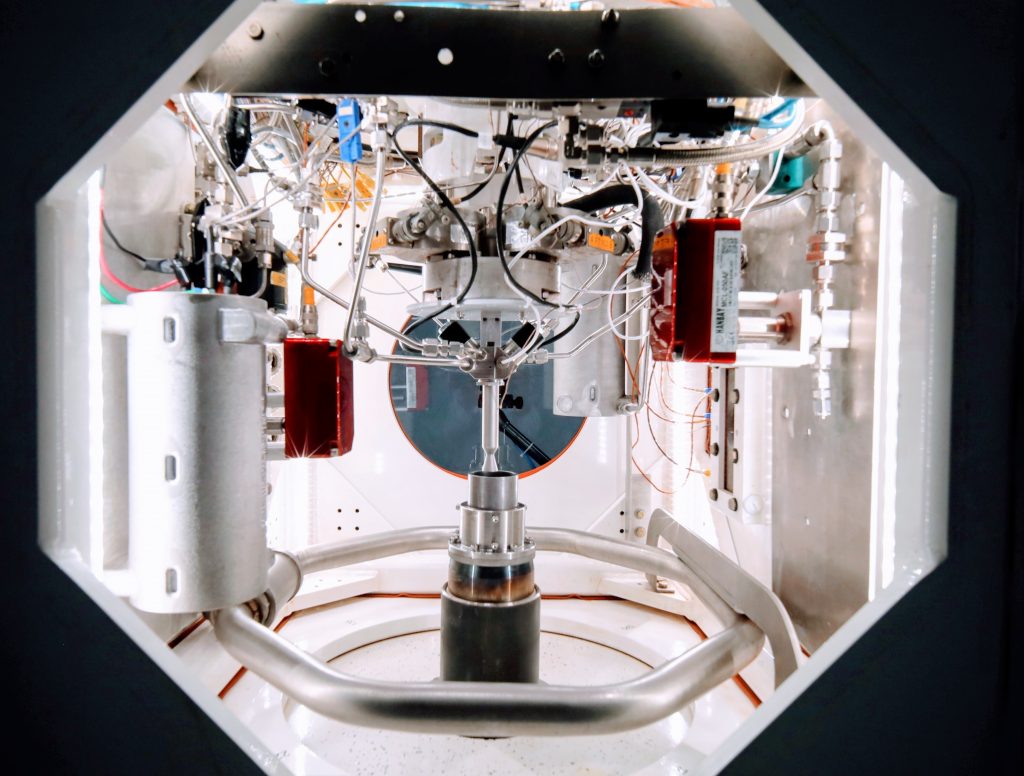

Featured image shows an Agile Space Industries launch site facility. Image via Agile Space Industries.