Industrial 3D printer manufacturerStratasyshas introduced a new software module, theDigital Anatomy Creator, for its Digital Anatomy 3D printers in order to enhance the production of 3D printed anatomic models.

Alongside the new software module, the company has partnered with third-party software vendorsSynopsys’简单软件扫描仪医疗和Materialise’模仿Inprint证明其数字解剖结构和J5 Medijet打印机将包含在FDA 510(k)清除的医学建模工作流中。

Elsewhere, Stratasys’ recently launched H350 3D printer has also been leveraged by German design firmDQBDto produce fully personalized cycling saddles that offer increased comfort and performance efficiency over those produced via traditional methods, while slashing lead times and production costs.

Advancing personalized healthcare

Stratasys的数字解剖3D打印机最初是在2016年推出的,用于为医疗领域的解剖模型生产。从那以后,打印机有been validated by global color authority Pantoneandreceived medical upgrades, including the capability tocreate models that mimic human bone。

The companylaunched its J5 MediJet 3D printerin June this year, designed specifically for medical applications such as patient-specific anatomical models, surgical guides, and medical tooling. The full-color system leverages Stratasys’PolyJet technologyand is compatible with a wide array of sterilizable and biocompatible 3D printing resins.

数字解剖创建器模块

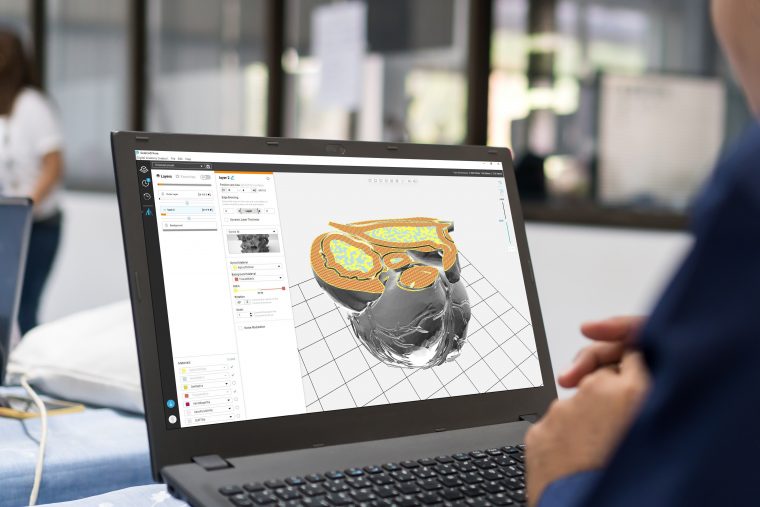

Now, Stratasys is advancing the capability of its medical machines with a new software module, the Digital Anatomy Creator, which allows users to produce patient-specific anatomic models that are a direct replica of a patient’s anatomy.

Through the module, users can easily manipulate material formations and customize the internal structures of their prints thanks to additional options and controls. This capability allows users to calibrate their printers’ materials to meet the specific requirements of each anatomic model, in order to customize and produce ultra-realistic models that behave and respond like the real thing.

数字解剖创建者还使用户能够在一个专门针对特定于患者的解剖学的社区中创建,复制和共享设计,从而从诊断到患者教育。

“The Digital Anatomy Creator is the missing link between the patient, the printer and the final printed 3D anatomic model,” said Seth Friedman, Manager of Innovation, Imaging and Simulation Modeling for Seattle Children’s Hospital. “This new software has allowed us to personalize our anatomic models to a mind-blowing level – we can now provide a level of care that is truly personalized to each of our patients, which is really important when working with children and their caregivers.”

Alongside the introduction of the new module, Stratasys has certified its Digital Anatomy and J5 MediJet 3D printers to be included in FDA 510(k) cleared medical modeling workflows, through partnerships with third-party software vendors. Synopsys’ Simpleware ScanIP Medical and Materialise’s Mimics inPrint software will enable Stratasys’ customers to access workflows for diagnostic anatomic modeling and point-of-care 3D printing.

“我们继续访问之旅,accurate, and realistic 3D medical modeling by deepening our structural pathology flexibility with the introduction of the Digital Anatomy Creator module and by validating our digital workflow with third-party segmentation software with FDA 510(k) clearance,” said Osnat Philipp, Vice President, Healthcare, for Stratasys.

“Our solutions allow providers to deliver best-in-class healthcare that leads to better outcomes and establishes a new level of care.”

优化骑自行车的鞍座生产

Moving away from the medical sector now, and Stratasys has revealed how its recently launchedH350 3D printerhas been leveraged to produce customized cycling saddles at scale.

Unveiled in April, the H350 is powered by Stratasys’Selective Absorption Fusion (SAF) technology, based on a high-speed sintering processoriginally developed by Xaar,哪个acquired in October。

The H350 has been deployed by DQBD to produce fully personalized bicycle saddles that reportedly deliver a higher level of comfort and performance efficiency compared to regular saddles. The design firm is 3D printing a number of the saddle’s load-bearing parts at scale using the machine, and says Stratasys’ SAF technology has so far enabled it to save up to £22,000 while slashing lead times from six months to just 10 days compared to injection molding processes.

DQBD首席执行官塞巴斯蒂安·赫斯(Sebastian Hess)说:“我们一直计划为增材制造业,以在Sam的创建中发挥关键作用 - 我们的自行车鞍座。”“实际上,我们考虑了添加剂制造的鞍座。该技术不仅可以迅速且负担得起的量迅速且负担得起的生产级零件,还提供了一个独特的机会,可以以一种无法用传统方法复制的方式来个性化产品。”

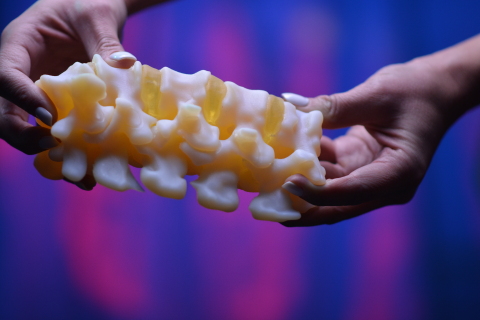

SAM马鞍由半刚性的个性化PA11 3D打印脊柱和3D热成型座垫组成。DQBD使用压力点和重量分布的软件映射,将马鞍的几何形状与骑手的身体和骑行位置相匹配,而鞍座的3D印刷脊柱中刚性和柔性区域的组成则提供了需要的支撑和适应。

According to DQBD, the combination of rigid and flexible zones will offer a higher level of comfort to the rider, while reducing fatigue. The entire saddle assembly is also glue-less, meaning the components can be easily separated and reintroduced into production at the end of the saddle’s lifetime.

Stratasys制造业业务部门EMEA和亚洲负责人Yann Rageul说:“我们肯定会看到企业准备最终用途零件的数量生产的趋势。”“ DQBD展示了H350及其SAF技术如何不仅可以通过宝贵的时间和成本节省来优化整个生产过程,而且还显示了为真正独特和高级设计的增材制造的部署 - 准备大规模生产。

“We are proud to see that the SAM saddle design DQBD created shows the advancements of additive manufacturing within the product development cycle – as the product concept was designed around additive manufacturing from the start.”

Subscribe to the3D打印行业通讯for the latest news in additive manufacturing. You can also stay connected by following us onTwitter并喜欢我们Facebook。

Looking for a career in additive manufacturing? Visit3D打印作业在行业中选择一系列角色。

订阅我们YouTube channelfor the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows数字解剖创建者允许用户推进功能医学模型的创建。通过Stratasys的照片。