波兰3D打印机制造商Omni3dhas patented a technology called the ‘Omni3D Cooling System’ that enables users to cool their Fused Filament Fabrication (FFF) machine’s extruders more effectively.

通过稳定喂食和沉积过程中的细丝温度,Omni3D表示,其组合的挤出机,打印头和组装系统提供了“质量明显更高”的部分。该公司已获得该技术的美国专利授予,现在希望它在已经有利的FFF 3D印刷领域的市场中获得吸引力。

Omni3D首席执行官PawełRobak说:“在Omni3D,我们希望提供最佳的3D打印解决方案,以生产具有出色尺寸准确性和稳定性的印刷品。”“我很自豪,我们可以为3D打印社区带来更多价值,并且我们的专利现在已在美国市场获得批准。我们认为我们的解决方案代表了挤压过程的重要改进。”

Omni3d的FFF打印投资组合

Since being founded in 2013, Omni3D has expanded its reach dramatically, and its client base now ranges from multinationals such asSiemens和马勒,给国防承包商BAE系统。目前,该公司的产品包括多个版本Omni200,,,,Omni500 Lite,,,,Omnistart和Factory 2.0单位以及细丝,旨在满足工业,汽车和教育需求。

借助其Omni3D系列机器,该公司已经启动了一套具有缩放功能和容量的用户友好系统,以便采用者可以选择最适合其用例的系统。虽然入门级Omnistart具有200 x 200 x 150毫米的构建体积,最高打印头温度为260°C,但功能较强的Omni500较大,其打印头可以在360°C安全地运行。

For engineers seeking an FFF 3D printer that can take on more demanding applications, Omni3D’s Factory 2.0 machines are even bigger. These feature 500 x 500 x 500 mm build volumes, and come fitted with enclosed heating chambers. As a result, the Factory 2.0 is capable of creating large-format prints from the engineering-grade Thermec Zed, in addition to ABS and CPFA industrial thermoplastics.

以前,该公司的技术已应用于3D print prototypes for the Hussarya这是一款不断重新开发的波兰超级跑车,从最初的设计到八年来的公路法律GT3赛车。在更多的最终用途应用中,Omni3D也与塞浦路斯工业大学,开发一个3D打印的生物燃料反应堆能够将二氧化碳变成替代燃料。

OMNI3D冷却系统

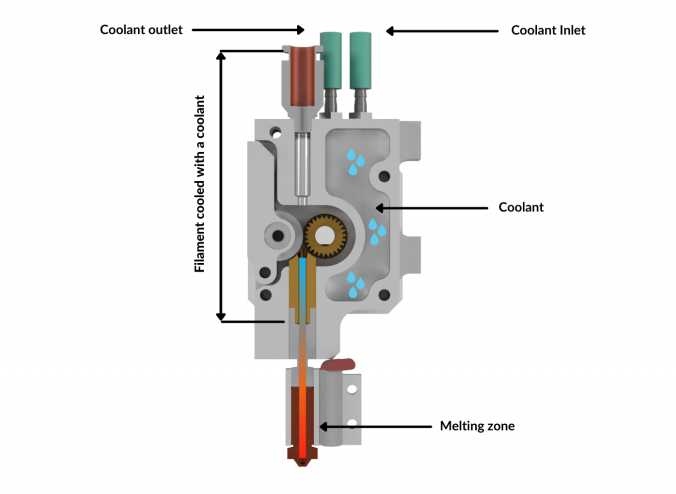

尽管FFF是市场上最受欢迎的3D印刷形式,但Omni3D表示,该技术仍有许多领域需要进一步研究。该公司特别认为对用户的滋扰的领域是挤压器过热。在没有冷却的情况下,该公司指出,细丝可以加热到软化温度,从而导致它们在挤出机的喂养区内变形。

反过来,这可能会导致挤出机的齿轮系统将材料“咬合”,从而有效地改变喂食量,最终以不一致的印刷品达到顶点。为了解决这个过热的问题,Omni3D提出了一种在丝线轴承和齿轮之间“抓住”细丝时冷却挤出机的方法,从而有助于稳定且可重复的塑料挤出。

在这样做的过程中,该公司发现稳定挤压温度的关键是改善了FFF机器的膝盖丝夹系统的工作条件。这些需要保持足够冷却,以确保使用正确的力将细丝压入打印头部,因此,为了使其成为可能,Omni3D已经开发了一种挤出机设计,其身体也扮演了散热器的作用。

有效地,该公司的挤出机可以通过其身体吸收热能,然后通过冷却液体将其传输到冷却器之前,从而将其驱散到环境中。通过从钛和铝创建系统,并绕开了对散热器的需求,Omni3D设法使其既更轻又紧凑,这也增加了其吞吐量。

同时,挤出机致力于最大程度地降低错误阶段材料变软的风险,从而减少了过度或不足的机会,同时改善了FFF打印机电动机的运行。与仅使用G代码材料设置相比,该系统还可以为用户提供更大的控制丝饲料量和打印精度。

“The basic idea of the system was to lower the temperature of the filament in the heated chamber,” explains Krzysztof Kardach, Chief Technologist of Omni3D. “By stabilizing it at a temperature far from being softened, the filament is transported more stably by the extruder to the nozzle. This functionality allows our printers to work with a variety of filaments and allows greater control over the feed pressure of the plasticized filament.”

“By cooling the extruder in the place where the filament is ‘caught’ between the pressure bearing and the extruder gear, we obtain a very stable and repeatable amount of extruded material,” he adds. “In the absence of cooling, the filament in the extruder may heat up to the softening point. The heated filament after compression in the extruder may deform from a circular cross section to an elliptical, and the gear will ‘bite’ more; thus changing the effective amount of material fed.”

A US-patented extruder design

Omni3D将这种挤出机设计整合到3D打印机中后,现在也在美国颁发了专利。根据专利号授予美国2019/0184633 A1,,,,’ the firm’s first patent in the country not only covers its heat-dissipating extruder design, but a modular head assembly system that works to further protect against potential print errors.

实际上,该设备的双头布局可以通过使用户同时控制两个细丝的软化温度参数,从而更易于切换打印头。除了使不同类型的材料用于零件的基础和支撑外,该系统还有助于使它们在进食之前和期间保持冷却,从而可以产生更好的过程稳定性。

“多亏了这个专利技术的使用,the Omni3D system is not only one of the most versatile in its application, but through its cooling elements, we stabilize the operation of the entire printer,” concludes Tomasz Garniec, Global Sales Manager of Omni3D. “This, along with the technological aspect, makes equipped Omni3D printers devices that have a greater feeling of the process, and guarantee stability for many hours of printing.”

提名2022 3D印刷行业奖现在打开。您认为谁应该成为今年演出的入围名单?立即进行投票,让我们知道。

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the3D打印行业通讯或跟随我们Twitter或喜欢我们的页面Facebook。

当您在这里时,为什么不订阅我们Youtubechannel? featuring discussion, debriefs, video shorts and webinar replays.

您是否正在寻找添加剂制造业的工作?访问3D打印作业在行业中选择一系列角色。

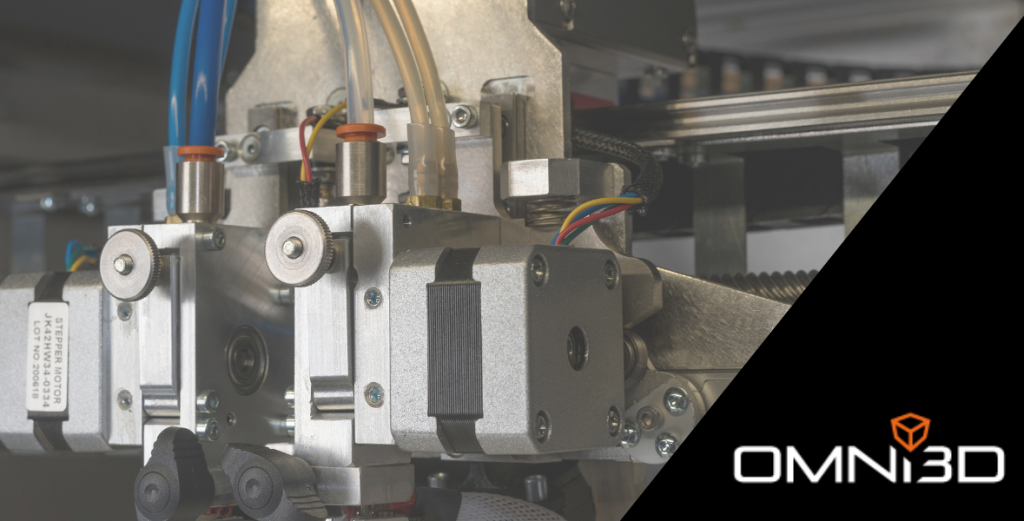

Featured image shows a printhead with the Omni3D Cooling System. Photo via Omni3D.