纳米’s Tera 250 technology lifts the lid for designers and manufacturers in their quest to embrace the inherent advantage of AM, and enables them to exploit the ability that exists through 3D printing to build complex parts in small, medium, and high volumes in a timely and cost-effective fashion. We caught up with Avi Cohen, Global EVP Sales at纳米about the disruptive nature of the company’s micro AM technology, and how it has navigated issues related to the global COVID pandemic.

3D打印行业: How have things been at Nanofabrica during the COVID pandemic?

阿维·科恩(Avi Cohen):Covid主要扭曲了我们与客户和潜在客户正确互动的能力。随着大流行的锁定因素开始缓解,今天我们正通过在各种领先的贸易展览和活动中处于重要地位,并参加在线和面对面的活动,使我们能够更加容易地参与其中与我们的潜在客户群。但是,我们还没有让草生长,并且在过去的18个月中,我们已经增加了用户基础,越来越多的公司看到了使用Micro AM解决方案进行精确塑料零件生产的商业优势。

3D打印行业: Can you briefly explain how the Tera 250 works?

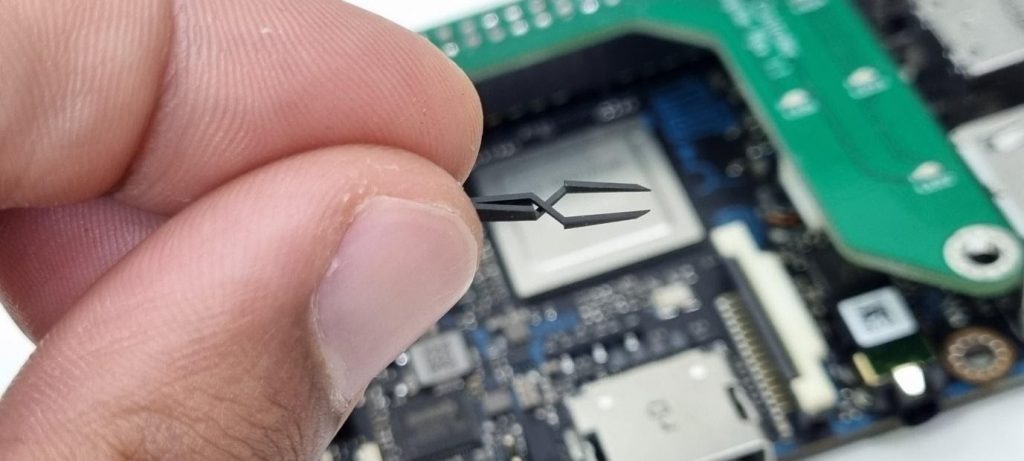

阿维·科恩(Avi Cohen):The Tera 250 is based around a Digital Light Processor (DLP) engine, but to achieve repeatable micron levels of resolution combines DLP with the use of adaptive optics. This tool in conjunction with an array of sensors, allows for a closed feedback loop, the reason that Nanofabrica’s Tera 250 can achieve very high accuracy while remaining cost-effective as a manufacturing solution. In addition, through rigorous R&D, Nanofabrica has managed to develop its own proprietary materials (based on the most commonly used industry polymers) which enable ultra-high resolution in parts built.

3D打印行业:您的客户通常使用TERA 250?

阿维·科恩(Avi Cohen):Our customers typically use our technology for in-house production of precise plastic parts for prototyping or full production runs, or they use them to service the demand for such parts through a contract manufacturing service.

一个关键客户是以色列凯撒利亚的Aran研发,它认为使用TERA 250将产品创新推动为最重要。AM允许使用传统制造工艺制造具有几何复杂性的零件,因此TERA 250因此将Aran R&D处于独特的位置,以满足各个行业的需求,以实现极其准确和创新的微型零件。

Moving forward, 3D printing / AM will continue to be used as a replacement for traditional manufacturing technologies, and this will continue to be focussed on applications where the use of the technology reduces the time and cost of manufacturing as is the case with Aran. As a general rule of thumb, for 3D printing to be used as a rapid manufacturing technology for any given application it will have to have demonstrate at a minimum a 10-fold improvement in cost and/or time savings to offset the cost and risk associated with changing over from a traditional manufacturing technology. For Aran, this is absolutely the case, and proves that for them, 3D printing is a clear and efficient alternative to traditional manufacturing processes today.

我们还只是在美国爱荷华州阿肯尼市累积的领先的微型注射模制公司放置了一台机器。Using Nanofabrica’s technology, manufacturers can benefit from the inherent advantages that AM offers: part complexity with no increase in cost, eliminating expensive tooling, reducing part counts and the need for assembly, reduction of time-to-market, easy revision of part design, providing opportunities for mass customization, as well as reducing waste and energy costs.

这些好处导致Accumold投资Tera 250, an indication that AM and traditional technologies can reside side by side and be complementary to each other. This is perhaps how AM in general can work in real-time production scenarios.

The Tera 250 micro AM system empowers Accumold with new service capabilities, most notably in low and medium volume production runs where the cost of traditional tooling would render projects non-viable.

A main area of interest is the production of direct rapid soft tooling (DRST) with the Tera 250, which facilitates prototyping and low volume production without the lead times and costs associated with traditionally fabricated tooling. Prior to the launch of the Tera 250, DRST had been regarded as sub-optimal when viewed through the prism of surface finish, precision, accuracy, and repeatability, while the number of materials that could be processed has also been a limiting factor. The Tera 250 system addresses these challenges to reach micron-level resolution, produce high surface finish, and reduce the time-consuming and costly need to cut steel.

Nanofabrica取得了突破性的成功,该成功构造了使用TERA 250技术制造的单个DRST的大量部分。TERA 250成功地将标准的热塑性材料(例如PP,PE和ABS)注入了3D打印的模具,该模具由公司开发的新专有材料制造。

3D打印行业:下半年我们下半年的下半场是什么?

阿维·科恩(Avi Cohen):Well we look forward with some optimism, and hope that the move out of COVID restrictions continues. Moving forward, the key is to build on the momentum of the last 18 months, and Nanofabrica will be exhibiting at the upcoming Rapid 2021 and Formnext events. At Rapid 2021 13-15 September in Chicago, IL, USA Nanofabrica will be showcasing the parts that can be produced on the Tera 250 machine on booth E8540. At Formnext 16-19 November, Frankfurt, Germany, the Tera 250 machine will for the first time be accessible to a wide potential customer base, and attendees at both events are invited to engage with the纳米teamto discuss specific applications and their appropriateness to micro AM.