晶格,在许多3D打印应用中作为填充模式常见,是最近对最佳各向同性刚度的研究的主题。

由一个科学家团队在ETH Zurich,瑞士,本文于2018年9月首次在线发表,讨论了极端僵硬的晶格的潜在影响,不仅是对航空航天行业的潜在影响,还讨论了“热交换,热绝缘,声学和生物医学工程”的潜在影响。

特别是,该研究建立了一类新的超材料,称为“板岩”,这表明刚度“刚度是最高质量最刚性的桁架较高的三倍”。根据教授Dirk Mohr, specialist in Computational Modeling of Materials in Manufacturing at ETH Zurich, these new lattices “will be the design of choice” when the 3D printing industry moves into mass manufacturing.

桁架还是格子?有什么不同?

通常被削减在一起,“桁架”和“晶格”形状通常是彼此代名词的。Mohr教授解释说,援引世界上一些最具标志性的地标的说法:“桁架原理很古老。长期以来,它一直用于半缠结的房屋,钢桥和钢铁塔,例如埃菲尔铁塔。我们可以透过桁架晶格,因此通常被视为理想的轻质结构。”

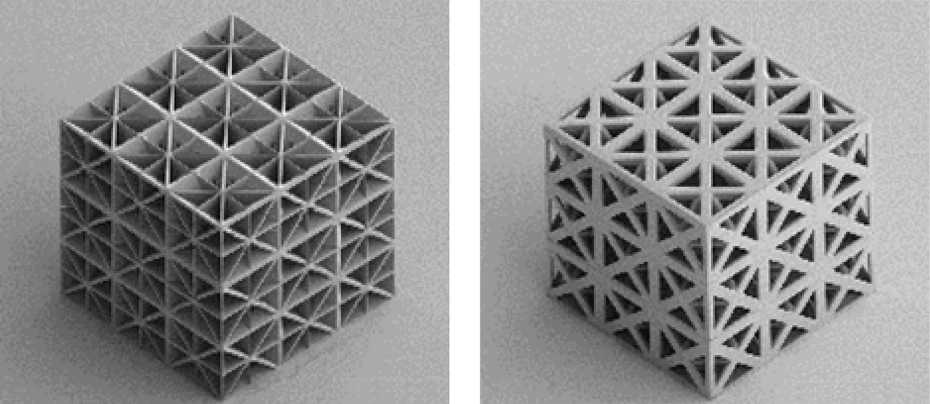

可以将桁架视为相互连接的束或支柱的地方,板更像是墙壁的簇。通过计算建模,MOHR教授的团队能够使用这些板创建竞争对手的晶格结构。差异可以在下图中注明。

大规模生产准备

由于它们的复杂性,3D打印是制造这些板块的唯一方法。作为概念的证明,这些板块的计算模型是由苏黎世团队在微观级别制造的。

使用nanoscribePhotonic Professional GTsystem, cubes measuring 200 x 200 x 200 μm were 3D printed. These were then compression tested, leading to a yield strength “within a few percent of the theoretical limits for isotropic porous solids.” Though only produced at this scale, the scientists believe that the plate-lattices could be theoretically manufactured at any size. It’s just a case of the cost.

“If these kinds of lattices were to be additively manufactured from stainless steel today, they would cost as much per gram as silver,” says Professor Mohr. “But the breakthrough will come when additive manufacturing technologies are ready for mass production. Lightweight construction, the current cost of which limits its practical use to aircraft manufacturing and space applications, could then also be used for a wide array of applications in which weight plays a role.”

这项研究的完整结果,“3D Plate‐Lattices: An Emerging Class of Low‐Density Metamaterial Exhibiting Optimal Isotropic Stiffness,”在线发布Advanced Materialsjournal. It is co-authored by Thomas Tancogne‐Dejean, Marianna Diamantopoulou, Maysam B. Gorji, Colin Bonatti and Dirk Mohr.

提名研究Team of the Yearin the 2019 3D Printing Industry Awards now.

For all of the latest updates, subscribe to the3D打印行业通讯, follow us onTwitter和我们一样Facebook。

加入3D Printing Jobsto find your next opportunity.

板块的计算模型。图片vie eth Zurich