研究人员在Rutgers University和路易斯维尔大学已经开发了一种融合的细丝制造(FFF)系统,该系统能够使用多个喷嘴快速在单个龙门上快速打印同一零件的不同区域。3D打印机是标准FFF速度的两倍。

Using an in-house developed slicer, the Multiplexed FFF or ‘MF3’ machine is able to deploy two or more printheads concurrently without needing additional gantries to control them individually. In doing so, the team says the MF3 could enable the creation of irregular builds, larger contiguous objects, and multiple distinct smaller parts at over twice the resolution and speed of comparative technologies.

“MF3 will change how thermoplastic printing is done,” says the study’s lead author Jeremy Cleeman. “We have more tests to run to understand the strength and geometric potential of the parts we can make, but as long as those elements are there, we believe this could be a game changer for the industry.”

Industrial FFF 3D printing’s tradeoff

根据研究人员的说法,与粉末或基于增值税的技术相比,FFF继续表现出具有更便宜,更适合3D打印的替代品的潜力。像Titan Roboticsgaining market traction with its pellet-loaded large-formatAtlas 3D printers, those familiar with FFF will know the process is already being scaled.

橡树岭国家实验室研究大区域添加剂制造(BAAM) has also given rise to a high flow-rate extruder and large nozzle-based approach, to upping FFF’s print speed. The technology uses a screw-based gantry-mounted extruder to melt and extrude pellets through a nozzle at flow rates of 3,000–8,000 mm3/s, with 5-8 mm-wide roads designed to facilitate faster flow.

However, the team says that matching this high throughput with the resolution needed to achieve fine features continues to prove difficult. While increasing road size (i.e., the size of extruded material beads) to raise throughput results in poor geometric fidelity, reducing road size to achieve high fidelity limits the volume of parts that can be produced.

制造商以前试图克服这一权衡的一种方法是,过多地打印了零件并加工了多余的材料,但这可能是一项昂贵且耗时的任务。继续获得牵引力的另一种方法是独立的双重挤压(IDEX)技术,该过程使用多个喷嘴同时打印同一部分的不同部分。

Such techniques, in which multiple extruders are mounted onto a single gantry, enable the production of twin parts in tandem on the same machine. That said, while the technology is marketed by the likes ofFlashForgeandrish3d, the researchers say it’s currently limited to periodic geometries. The team also claims that using one gantry per extruder only makes two printheads viable in IDEX setups.

Multiplexed Fused Filament Fabrication

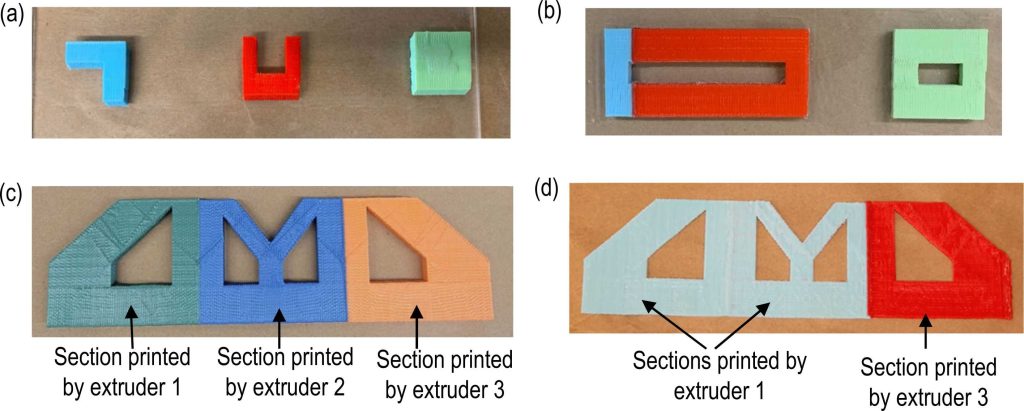

To overcome the perceived drawbacks of existing FFF technologies, the researchers have come up with their own system, composed of three off-the-shelf extruders on a single three-axis cartesian gantry. Unlike those of current IDEX machines, the MF3’s printheads are able to simultaneously create distinct sections of parts thanks to a selective deposition approach.

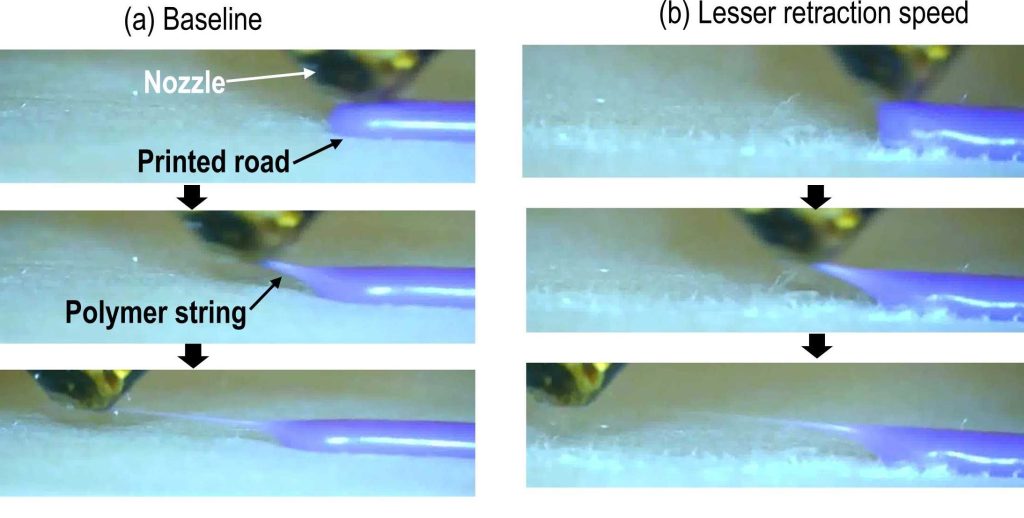

自定义切片机使团队的技术成为可能,该切片机旨在优化机器龙门臂的动作,并确定是否应激活喷嘴。实际上,这可以使软件精确地控制打印机的步进电动机的方向和速度,从而使灯丝可以独立地延长或缩回挤出机的液化器。

鉴于每个喷嘴的速度并不取决于它们是否沉积材料,因此该设备可以连续打印零件,同时避免任何潜在的重叠或碰撞。MF3的并发沉积功能还可以使零件以更高的分辨率和吞吐量的形式创建,而不是单脱位系统以及多物质构建。

实际上,在测试过程中,该机器能够以分辨率分辨率的2.5-4倍生产零件,并且随着进一步的喷嘴的结合,该团队表示,它也可能更快。进一步的实验还使研究人员使用其工具路线策略在同一床上同时打印大小零件,据估计将其交货时间减半。

Moving forwards, the engineers believe the throughput advantage of MF3 over single-nozzle printing will prove to be greater for larger batch sizes. Thus it could soon allow users to “overcome the reach-driven geometric limitations” of existing technologies and “realize new economies of scale and productivity.”

Advancing high-speed FFF 3D printing

FFF continues to be the subject of significant research into improving its speed and performance. In the past, Titan Robotics has worked withAutodeskto develop a五个p-printhead cronus 3D打印机目标与MF3相似。当2016年揭幕时,该系统被证明能够使用多个挤出机同时打印一个对象,但是,此后在开发方面几乎没有听说过它。

最近,在2021年2月,3D Systemsrevealed that it was working with贾比尔to launch ahigh throughput Roadrunner 3D printer。Equipped with the ability to print high-temperature filaments, the system is designed to act as the base of its High Speed Fusion (HSF) platform, and target the automotive and aerospace sectors.

Elsewhere, researchers at theUniversity of Nanteshave set out to investigateFFF 3D打印期间的传热和粘附。By quantifying the heat exchanges that take place in the process, the researchers attempted to identify the optimal set of print parameters, and maximize the mechanical properties of 3D printed parts.

研究人员的发现在其论文中详细介绍了“可扩展的、灵活的和有弹性的并行of fused filament fabrication: Breaking endemic tradeoffs in material extrusion additive manufacturing”,由杰里姆·克莱曼·亚历克斯·博格特(Jerem Cleeman Alex Bogut),布里吉什·曼格里亚(Brijesh Mangrolia),阿德琳·里普伯格(Adeline Ripberger),库纳尔·凯特(Kunal Kate),Qingze Zou和Rajiv Malhotra合着。

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the3D打印行业通讯or follow us onTwitteror liking our page onFacebook。

要深入研究添加剂制造,您现在可以订阅我们的Youtubechannel, featuring discussion, debriefs, and shots of 3D printing in-action.

您是否正在寻找增材制造业的工作?访问3D打印作业for a selection of roles in the industry.

Featured image shows a diagram indicating how the MF3 operates. Image via Rutgers University and the University of Louisville.