Clemson Universityhas established an $11 million cooperative agreement with the US Combat Capabilities Development Command of the Army Research Laboratory, known asDEVCOM ARL, to create new technologies that will speed up the development of new 3D printed components for the US military’s ground vehicles, air platforms, and munitions.

Throughout the project, Clemson University will leverage the direct metal printing, advanced plastics, and composites technology of 3D printer manufacturer3D Systems.

The project will involve the creation of an Artificial Intelligence (AI) powered “digital lifecycle platform” to enable the army’s engineers to design and test new components without physically building them, and the formation of a raw materials database for new potential 3D printing feedstock materials.

“This agreement is another example of Clemson’s growing emphasis on partnering with industry and the government to leverage the university’s research expertise to benefit our state and nation,” said Jim Clements, Clemson President.

“我为我们的教职人员所做的工作感到自豪,这将使这种尖端技术在为我们的军队创造下一代车辆和其他重要设备中发挥重要作用。”

Creating a digital lifecycle platform

One of the main aims of the project is to create a digital lifecycle platform that uses AI to help production engineers design, analyze, and build components more quickly at lower costs.

Once produced, the platform will enable users to develop a wide variety of large components with complex geometries and embedded multi-functionalities. These kinds of components could include vehicle parts with power transmissions, energy storage, sensing and self-monitoring functions, and the platform would help to optimize their overall size, weight, power, and cost (SWaP-C) efficiencies.

The ultimate aim of the platform is to enable engineers to design and test new components without physically building them.

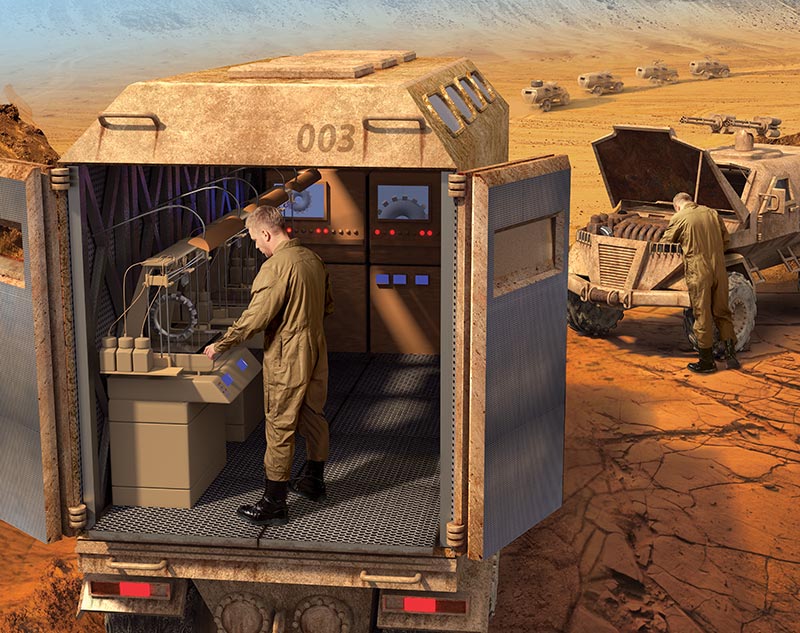

The first phase of the project will see $6.3 million funding be made available to support the ongoing research at the Clemson Composites Center, located in the Greenville Technical College’s Center for Manufacturing Innovation. Here, the Clemson researchers will leverage the technology and capabilities of the“world’s largest metal 3D printer”3D Systems is creating for DEVCOM ARL.

打印系统,即equipped with nine lasersand a large-format build chamber measuring 1m x 1m x 600mm will be used to address the ammunition, ground vehicle, helicopter, and missile defense needs of the Armed Forces.

Devcom ARL最近选择了3D系统,以参加一个单独的研究项目,旨在开发3D printed topologically optimized heat exchangers对于美国陆军,使用其DMP工厂500 3D打印机。

“3D Systems was founded on a spirit of innovation, and our customers’ unique applications fuel our efforts to create new technologies,” said Jose Doval, Advanced R&D Director at 3D Systems. “Through our collaboration with the US Army Research Laboratory, we’ve made tremendous strides in developing the world’s largest, fastest metal powder 3D printer. Expanding this work with Clemson University allows us to push the limits of the technology even further.

“This includes investigating new methods of in-situ detection, as well as ways to visualize the build in real-time from the data collected in each layer.”

Developing a raw material database

The Clemson researchers will also seek to establish a database of raw materials consisting of metals, plastics, and composite materials, to aid research into the properties of 3D printing feedstock.

研究人员将打印原材料的样品,并进行一系列测试,以测量其化学,机械和热物理特性,以创建潜在的新原料材料的数字模型。将来,子组件将是3D打印,考虑到全尺寸组件的复杂几何形状以及数据库材料的观察到属性。

“The database development as well as validation of the digital life cycle through experimental characterization and testing are enabled using the state-of-the-art infrastructure available at the Clemson Composites Center which includes 3D printers, thermophysical testing equipment, optical metrology, quasi-静态和动态的滴剂测试基础设施,加速老化设备,高速相机和光谱设备。

Collaborating on theMX倡议

Clemson University is also collaborating with the ARL on another project known as the MX倡议, which brings together a multidisciplinary team of faculty members to carry out fundamental and applied research to support the modernization and future capabilities of the US Army.

According to DEVCOM ARL, the collaboration with Clemson will help it to find new ways to advance the science of additive manufacturing while helping to create a pipeline of new talent within the sector. The collaboration will also aid in further expanding the applications of 3D Systems’ metal 3D printing technologies.

“Over the past few years South Carolina has seen record investment and growth, a large portion of which can be accredited to the willingness of our colleges and universities to partner with new and existing businesses,” said Governor Henry McMaster.

“克莱姆森(Clemson)和3D系统之间的项目强调了我们高等教育系统不仅提供高技能的劳动力,而且与我们的商业社区建立重要合作伙伴关系,最终导致南卡罗来纳州更强大的伙伴关系。”

订阅3D Printing Industry newsletter有关增材制造中的最新消息。您也可以通过关注我们来保持联系推特和喜欢我们Facebook。

寻找添加剂制造业的职业?访问3D Printing Jobsfor a selection of roles in the industry.

Featured image shows克莱姆森大学项目负责人斯里坎特·皮拉(Srikanth Pilla),法迪·阿卜杜拉瓦德(Fadi Abdeljawad)和帮派李(从左到右)以及刘·刘(Shunyu Liu)和拉胡尔·赖(Shunyu Liu)和拉胡尔·赖(Rahul Rai(Rahul Rai)(未图)将推动格林维尔克莱姆森复合材料中心的研究。通过克莱姆森大学的照片。