2020年3月的月份发布了增材制造安全标准,新的3D印刷材料合格的,创新的生物材料发现,甚至计划3D打印炸药。

读202年3月的突出的发展0, which involved the likes of ASTM International, ExOne, Wohlers Associates, Siemens, Stratasys, Relativity Space, and the UK Defense Agency.

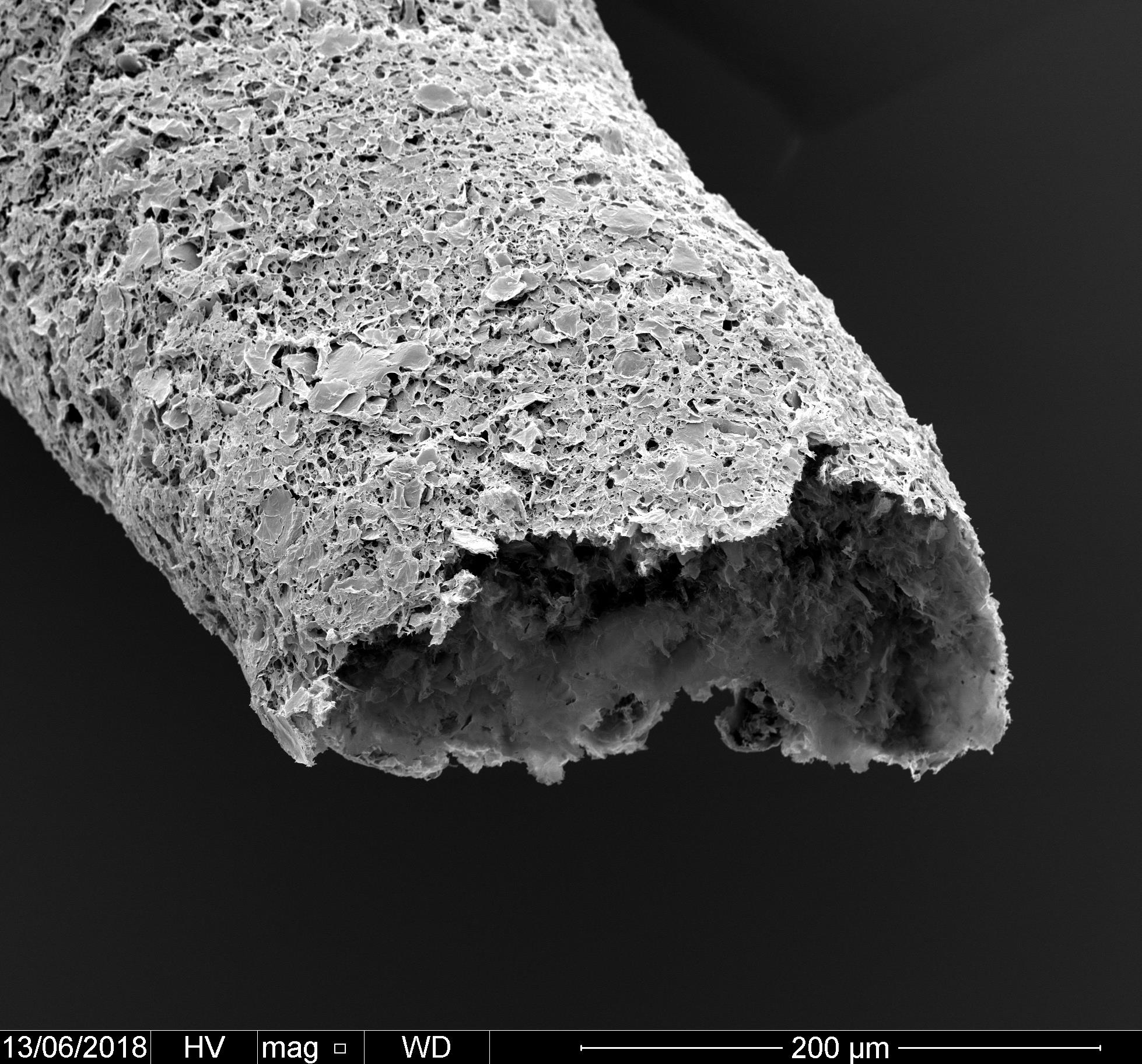

3D printing vascular structures

本月初看到了一项新的研究,探索了3D打印石墨烯氧化物具有蛋白质形成管状结构的可能性replicate vascular tissues.Led by Professor Alvaro Mata at theUniversity of NottinghamandQueen Mary University of London, the researchers precisely mixed the two components to form a biomaterial that could then be used as a bio-ink to 3D print intricate structures with fine resolutions.

“This work offers opportunities in biofabrication by enabling simultaneous top-down 3D bioprinting and bottom-up self-assembly of synthetic and biological components in an orderly manner from the nanoscale,” said Mata.

“This could enable the recreation of vasculature in the lab and have implications in the development of safer and more efficient drugs, meaning treatments could potentially reach patients much more quickly.”

Relativity Space successfully lands new HQ

同时,火箭建筑公司Relativity Spacesecured its new headquarters in the heart of the US’s aerospace community in Long Beach, California. Home to both the firm’s business operations and its automated metal additive production line, the facility will enable Relativity to produce Terran 1, the world’sfirst fully 3D printed rocket。

More recently, the firm从投资者那里筹集了5亿美元尽管尚未成功将Terran 1送入轨道,尽管目前正计划于2021年进行商业发布。

Siemens ups investment in Stratasys for 30-year rail project

Elsewhere,Siemens Mobility Servicesinvested in two new industrial-gradeStratasysFortus 450mc 3D printers to support spare part production for 13 additional high-speed Velaro trains Siemens is building for Russian train firmRZD。

The new trains will be added to an existing fleet of 16, with a 30-year agreement to maintain and service the trains also part of the deal. The two Stratasys machines were installed in St. Petersburg and Moscow to enable Siemens’ team to rapidly3D print rail replacement components按需,作为西门人在俄罗斯的“轻松散发部分”网络的一部分。

Reversible 4D printing

通过合并下一个维度,4D打印自然是从3D打印的下一步,涉及3D打印对象随时间变化的形状。3月,来自新加坡技术大学(SUTD) andNanyang Technological University(NTU)提出了一种方法这个过程可以颠倒- 即,该物体会更改为原始的3D打印形状 - 无需水凝胶或人类输入。

“虽然可逆的4D打印本身是一个巨大的进步,能够使用更强大的材料,同时确保形状变化期间更精确的逆转是革命性的,因为它使我们能够产生复杂的结构,这些结构无法通过常规制造来实现,”Sutd的首席研究员兼工程产品开发主管Chua Chee Kai教授。

“By relying on environmental conditions instead of electricity, it makes it a game-changer across various industries, completely changing the way we design, create, package, and ship products.”

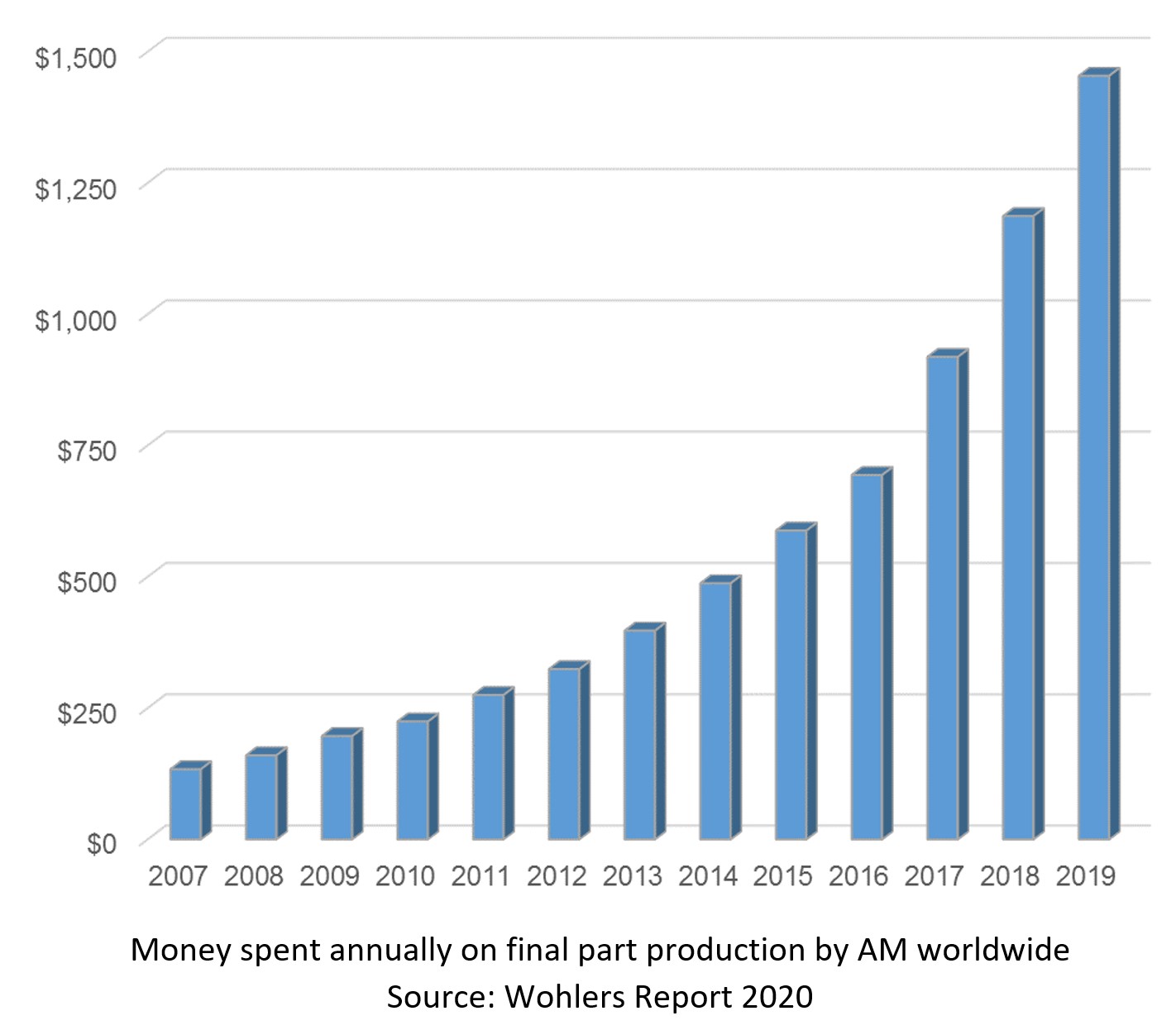

Wohlers Associates发布年度3D打印报告

In mid-March,Wohlers Associates, the Colorado-based additive manufacturing consultancy firm of Terry Wholers, published the 25th consecutive installment of its关于3D打印状态的报告。This year,该报告详细信息on additive manufacturing industry growth, particularly regarding maturing and emerging applications of 3D printing for series production.

该报告还包括对牙科行业添加剂制造的审查,讨论了77个价值11亿美元的早期投资,并在过去12个月中列出了72个行业合作伙伴关系。

DSTL’s explosive plans

TheDefense Science and Technology Laboratory(DSTL), an executive agency sponsored by the UK’sMinistry of Defense(MOD), revealed it had begundeveloping 3D printed explosives在一个试图为爆炸性效果创造新的可能性并降低运输和存储成本的项目中。3D打印将用于在国防部的未来能源项目中生产新的能源配方,自2015年成立以来,该项目已有近1000万英镑的投资。

“Energetics knowledge and experience is vital for the UK to develop the best equipment, platforms, and operational assets,” the DSTL stated.

“We need to know how energetic systems damage or defeat our platforms and how we can counter threats, so we can advise on things like countermeasures, detection, safety, transportation, and disposal, all while working with explosives in accordance with legislation.”

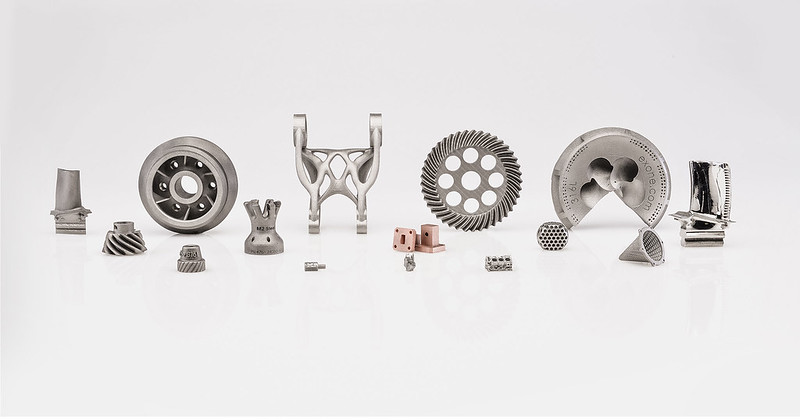

21 new qualified materials from ExOne

Shortly after, leader in industrial sand and metal binder jetting 3D printers,Exone, announced the21种新材料的资格for use in its machines, in addition to its brand new qualification system. The firm’s growing set of qualified materials came as a result of its extensive list of customer collaborations, including partnerships withNASAandVirginia Tech。

As of the announcement, owners of ExOne printers had the option of choosing between 10 single-alloy metals, six ceramics, and five composites, alongside over 24 additional powders qualified for 3D printing. Since then, ExOne hasqualified Inconel 718for use with its metal binder jetting systems and reached an agreement with the ceramics producerITOCHU Ceratechtovalidate its Naigai Cerabead materialsfor use with its sand 3D printers.

AM设施安全标准协议

Safety consulting and certification firmUnderwriters Laboratories(UL)和全球标准开发人员ASTM International签署了一份我morandum of understanding (MoU) for an ASTM-ISO standard for additive manufacturing facility safety management. Thefirst agreement of its kindbetween the two bodies, the MoU sought to establish a framework for developing an international, dual-logoISO和ASTM标准。

UL副总裁全球标准菲尔·皮奎拉(Phil Piqueira)表示:“这种合作伙伴关系汇集了组织的专业知识和共同渴望推动全球安全的愿望。”“它利用ASTM的技术委员会以及与ISO的关系以及我们的文档和研究,以推动影响并积极影响国际标准格局。”

新加坡联合行业计划进入第2阶段

Elsewhere, theMaritime and Port Authority of Singapore(MPA), Singapore’sNational Additive Manufacturing Innovation Cluster(namic)和Singapore Ship Association(SSA)宣布Phase 2 of their Joint Industry Programme(JIP) to integrate 3D printing into the marine sector.

During Phase 2, the organizations will focus on selecting applicants to 3D print the parts identified as suitable for additive manufacturing in Phase 1, and install them onboard vessels. Applicants will then have to produce a comprehensive project report outlining the technical assessment and commercial viability of each component.

JIPs conclude for Adoption of AM in oil and gas sector

Ending March’s news round-up is the conclusion of two Joint Industry Projects (JIPs) which sought to establish guidelines for the production and qualification of3D printed parts for the oil and gas and maritime industries。由国际分类学会组织DNV GL, and involving 20 different partners, the JIPs aimed to develop guidelines to help qualify parts produced byLaser Powder Bed Fusion(LPBF) andWire Arc Additive Manufacturing(WAAM)在两年内。

第一个计划集中在创建框架上,以确保使用WAAM和LPBF生产的组件满足质量和安全要求,而第二个项目则致力于开发用于零件选择,供应链设置和经济生存能力的“工具箱”。

订阅3D Printing Industry newsletterfor the latest news in additive manufacturing. You can also stay connected by following us on推特and liking us onFacebook.

Be sure to subscribe to the Another Dimension podcast on your chosen podcast player to make sure you never miss an episode.

Looking for a career in additive manufacturing? Visit3D Printing Jobs在行业中选择一系列角色。

Featured image shows RZD high-speed Sapsan train fleet. Photo via Stratasys.