Click to see all articles in our2021 3D Printing Industry Review of the Yearseries.

Fresh off the back of a turbulent 2020, January 2021 saw the first of what would turn into a year of significant 3D printing business moves, with the huge amounts of funding raised leading to considerable market consolidation. In other areas, like concrete 3D printing, the scalability of these technologies also made big strides forward during the month, as did research into novel eco-friendly materials.

Read on for the standout developments in January, including those of Pyrogenesis, Formlabs, Desktop Metal, COBOD, WASP, Protolabs, Aectual, Nano Dimension, Massivit3D and more.

AM investment hits new heights

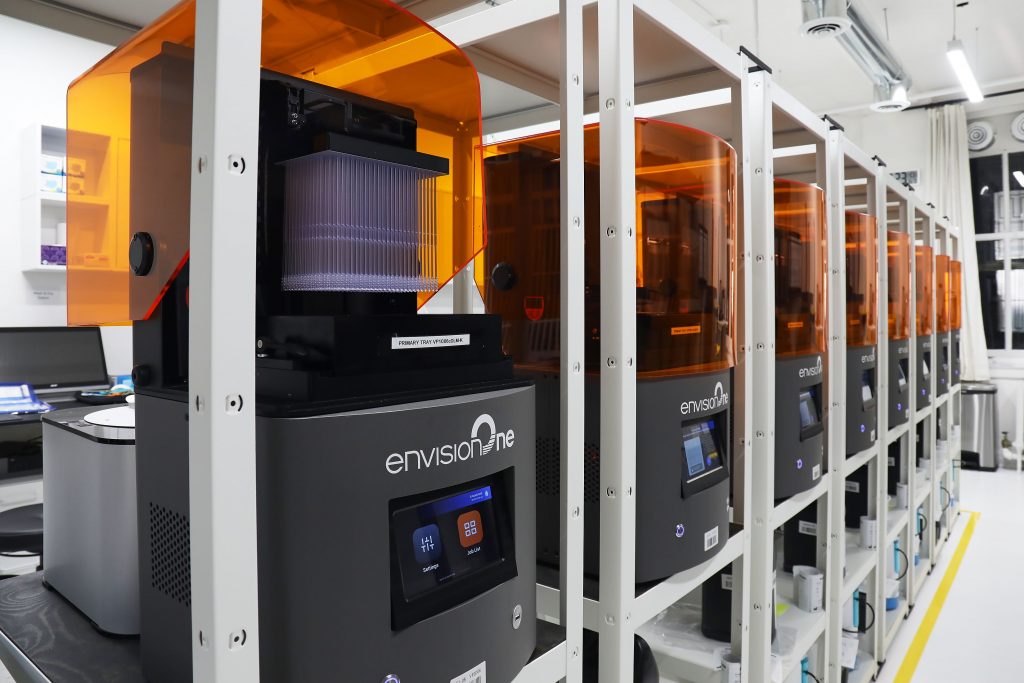

Over a matter of days in mid-January 2021, 3D printing shares worth some $912.5 million were made available or changed hands. First to make one of these mega-deals was 3D printer manufacturerDesktop Metal, whichbought up EnvisionTEC for $300 million. The firm’s acquisition effectively enabled it to enter the DLP market, and expand further into the dental, jewelry and bio-fabrication industries.

The next day, digital manufacturing providerProtolabsannounced plans to shell out $280 million on theacquisition of 3D Hubs. Since completing the move, Protolabs has leveraged its new subsidiary’s network of partners and 3D printing capabilities to broaden its pricing and lead time options for customers, as well as renaming it to simply ‘Hubs.’

At around the same time, electronics 3D printer manufacturerNano Dimensionalso revealed that it would be making a further$332.5 million worth of sharesavailable to investors, via a registered direct offering. Once completed, the move saw the company take its total capital raised to $1 billion, funding it later deployed tobuy DeepCube for $70 millionandacquire microprinting specialist Nanofabrica.

Kicking-off a year of IPOs

FollowingDesktop Metal’s $580 million IPOalongside SPAC Trine Acquisition, several other 3D printing firms also opted to go public in 2021, with the aim of turning renewed interest in the technology into liquid capital. In early January, powder producerPyrogenesisbecame the first such firm to weigh up an IPO, before it went on tosubmit a formal applicationto list its shares on the NASDAQ exchange.

当时,该公司的首席执行官P. Peter Pascali表示,他相信热原的生成“进入增长阶段的增长”,因此他期望这一举动“在金融界和潜在客户中都提高了对其产品的认识”。Pascali的预测在本月底的第四季度收入结果得到了验证projected up to 367% growth.

Over in Israel, meanwhile, large-format 3D printing firmMassivit3Dwasplanning to go publicon the Tel Aviv Stock Exchange (TASE) as well. When it did eventually conduct its IPO in March 2021, the company was able to raise $50 million in funding through the move, leading its CEO Erez Zimerman to declare that it “testified to the market’s substantial evaluation for the solution that Massivit3D provides.”

Formlabs enters the SLS arena

Amid all the cash changing hands in the 3D printing industry during January,Formlabswas also able to carry out one of the year’s most significant system launches. Previously an SLA 3D printer manufacturer, the firm’snew Fuse 1 machineallowed it to enter the industrial SLS market for the first time, alongside its Fuse Sift unit and proprietary Nylon material.

Designed to address the needs of those engineers, designers, and manufacturers seeking a high-quality functional prototyping or short-run production tool, the benchtop system features a modular 165 x 165 x 300mm build chamber and powerful 10W fiber laser, which according to the firm’s CEO Max Lobovsky, make it an attractive low-cost SLS entry point.

“The Form 1 redefined SLA printing for the AM industry ten years ago, and now the Fuse 1 is bringing the same reliability and accessibility standard that Formlabs customers expect,” Lobovsky said at the time. “SLS 3D printing shouldn’t be solely for those with big budgets, it needs to be accessible so all companies can benefit from the design freedom and high productivity it provides.”

Concrete 3D printing ramps up

Over in the construction sector, January saw 3D printing use scaled to new heights, withLarsen & Toubro Constructionleveraging it to erectIndia’s first two-storey building. Built from locally-sourced materials with a large-formatCOBODsystem, the robust structure featured vertical reinforcement bars as well as welded mesh distributors, and ultimately proved compliant with the country’s building codes.

That month, Italian 3D printer manufacturerWASPalso announced it had completed the build of its unique‘TECLA’ organic house. Designed byMario Cucinella Architects, the sustainable dome-shaped structure was constructed from all-natural feedstock, and built as a proof-of-concept and blueprint for a newly-sustainable housing model.

Elsewhere,Aectualrevealed that it would be taking a different approach to additive manufactured architecture, by launching its ownonline 3D printing service. Unveiled atCES 2021, the beta platform initially offered users the chance to order custom household design elements, such as panelling, fixtures or flooring made from eco-friendly materials.

在发射,Aectual海德薇Heinsman创始人之一的年代aid the platform would “enable world-class architects, designers and brands to realize their own bespoke designs on-demand, at any scale, in any building and to create truly unique 100% sustainable products, without being slowed down by extensive prototyping.”

Sustainable production progresses

In similarly sustainability-related news, polymer manufacturerINEOS Styrolutiondeveloped astyrenics-based 3D printing powder, with the potential to provide users with 67% energy savings compared to PA12. Created as part of its ‘PolySLS’ project, the firm said the material could go into mass-production, but this would depend on further testing, as well as product demand and its overall capacity.

On the flipside, researchers at theUniversidade NOVA de Lisboa(UNIDEMI) also highlighted the lack of circularity that goes into creating such materials. Following anin-depth literary review, the team found that industrial waste is rarely re-used in 3D printing, yet doing so could net manufacturers both profitability and sustainability gains.

“Plastic waste seems to be the material that’s often a point of interest in studies, and a few have identified possible avenues for having industrial symbiosis networks within the AM industry,” stated the researchers in their paper. “This could be more profitable and achieve a real positive impact on our planet.”

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the3D Printing Industry newsletteror follow us onTwitteror liking our page onFacebook.

For a deeper dive into additive manufacturing, you can now subscribe to ourYoutubechannel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit3D Printing Jobsfor a selection of roles in the industry.

Featured image shows the row of EnvisionOne 3D printers used by PrintParts to fabricate COVID-19 nasal testing swabs in NYC. Photo via PostProcess.