研究人员瑞士联邦材料科学和技术实验室(EMPA)已使用3D打印来创建可持续的新产品超级电容器。

The fully-3D printed battery, composed of a flexible cellulose and glycerol substrate, patterned with a conductive carbon and graphite-laden ink, is able to withstand thousands of charging cycles while maintaining its capacity. Thanks to its biodegradable base, the novel cell can also be composted once finished with, potentially making it an ideal tool for tackling the world’s electronic waste issues.

寻找可持续的“ EDLC”

一个ccording to the EMPA scientists, the recent boom in electronic wearables, packaging and Internet of Things (IoT) applications, has seen the global number of these devices rise to 27 billion. However, given their short life cycle, and the fact they tend to be powered by non-renewable lithium ion or alkaline cells, many such products will eventually be landfilled, worsening the global ‘e-waste’ problem.

In an effort to develop more eco-friendly energy storage devices, scientists have therefore begun to experiment with electrical double layer capacitors, or ‘EDLCs.’ These high-capacity, fast-charging supercapacitors can at least partially be manufactured from biodegradable materials, potentially making them an ideal replacement for normal batteries, which often require specialized disposal services.

一个lthough a significant amount of research has gone into EDLC R&D, their varying parts such as electrodes and current collectors, can be difficult to produce via a single manufacturing process. What’s more, many prototype EDLCs are partially-3D printed at most, necessitating their time-consuming and expensive assembly or post-processing, which make them unattractive as commercial ventures.

一个‘state-of-the-art’ supercapacitor

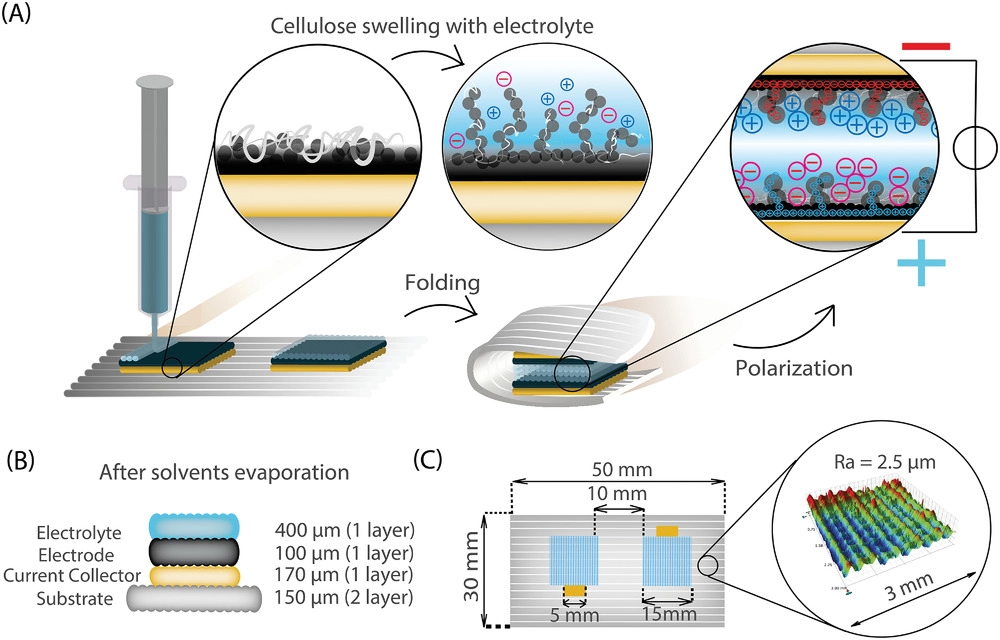

To streamline EDLC production and create an eco-friendly battery of their own, the EMPA team turned to DIW 3D printing, which they used to manufacture two half cells before folding them together. In practise, this meant printing the unit’s substrate base first, then depositing its electrode and conductive graphite-infused electrolyte layers on top, in a process that after some tweaking, yielded a functional battery.

Empa的纤维素和木材材料实验室的Xavier Aeby说:“这听起来很简单,但根本不是。”“它进行了一系列扩展的测试,直到所有参数都是正确的,直到所有组件都从打印机和电容器起作用为止。”他补充说:“作为研究人员,我们不想只是摆弄,我们也想了解材料内部发生的事情。”

一旦他们的超级电容器原型准备就绪,科学家就试图通过对其开放表面电压进行测量,以通过对0.5 V的费用来测试其电荷保留率。根据研究人员的说法,他们的设备在150小时后仍有30%的费用,其性能“与最先进的碳超级电容器的绩效一致”。

Interestingly, the researchers found that the capacity of their supercapacitor also fluctuated for two weeks after fabrication then settled, while it later remained functional after eight months in storage, and when they had finished their experiments and attempted to compost it, they were able to dissolve around 50% of its mass over the course of nine weeks.

During testing, the team’s device was ultimately capable of powering a 3V alarm clock under mechanical stress, as well as operating at wildly varying temperatures. As a result, with further R&D, they say it could be deployed on a wider scale, to sustainably power low-voltage smart devices such as those used within environmental monitoring, e-textiles or healthcare applications.

Printed batteries: ready for market?

While 3D printed batteries remain at a relatively early stage of development, there are promising signs that the technology is progressing towards being end-use ready. Previously known as KeraCel, the rebrandedSakuu Corporationhas recently announced plans to launch its first固态电池(SSB)3D打印机在2022年,据说其容量远高于目前的锂离子设备。

In the UK, 3D printer manufacturerPhotocentrichas established aninternal battery R&D division,它正在尝试设计自己的新节能存储设备。通过减少电池电极的尺寸和重量,该公司最终旨在开发一个更适合汽车应用的单元,据说它是针对即将到来的特斯拉Giga factory with its creation.

In similar, albeit more experimental research, a team at the曼彻斯特大学已经开发了一个3D printable ‘MXene’ ink, and used it to produce prototype supercapacitors. During testing, the scientists said that their additive manufactured electrodes demonstrated both the high capacitance and energy density needed to power the cars or mobile phones of the future.

研究人员的发现在其论文中详细介绍了“Fully 3D Printed and Disposable Paper Supercapacitors”,由Xavier Aeby,Alexandre Poulin,Gilberto Siqueira,Michael K. Hausmann和GustavNyström合着。

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the3D打印行业通讯or follow us on推特or liking our page onFacebook。

为了深入研究添加剂制造,您现在可以订阅我们的Youtubechannel, featuring discussion, debriefs, and shots of 3D printing in-action.

您是否正在寻找添加剂制造业的工作?访问3D打印作业在行业中选择一系列角色。

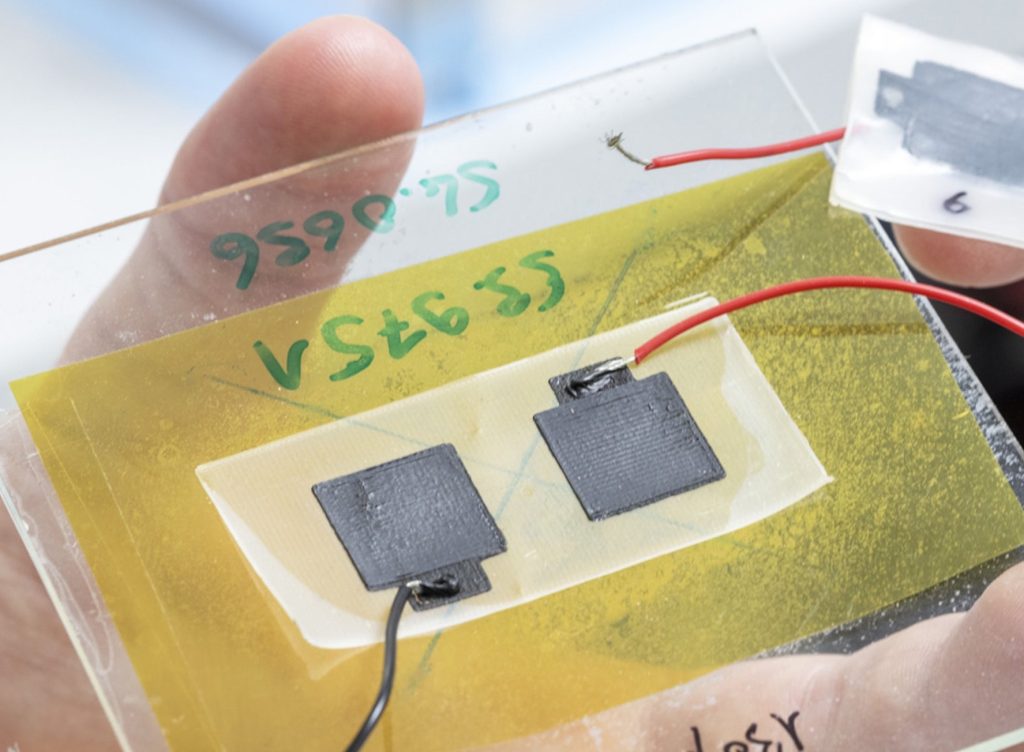

Featured image shows the the EMPA researchers’ 3D printed supercapacitor. Photo via EMPA.