三菱电气公司, a major Japanese manufacturer of electronics and electrical equipment, has announced the launch of a new metal 3D printing system.

即将到来的AZ600是一种定向的能量沉积(DED)3D打印机,可以在两种型号中使用。据该公司称,该系统将基于激光,并通过将焊接电线熔化为3D打印近网状金属零件来工作。客户还将能够利用AZ600在航空航天,汽车和海上等部门中的组件维修和维护应用程序。

To complement the launch of the 3D printer, Mitsubishi is also establishing a new contract printing service that will utilize the metal system. The firm will offer product design consultation, prototyping, and general advice about metal 3D printing, expecting the move to help accelerate the adoption of additive manufacturing.

三菱和添加剂制造

看到大型跨国公司投资于增材制造,这总是很有趣的,但这并不是三菱第3D印刷的第一次跑步。2018年,该公司开发了高精度金属“点形成” DED 3D打印为汽车和航空航天行业生产近乎整合的零件的过程。

Last year, Mitsubishi Electric also partnered with UK-based post-processing specialistAdditive Manufacturing Technologies(AMT) to develop afully automated post-processing machine for 3D printed polymer parts。据报道,这是安全和咨询公司批准的同类机器Underwriters Laboratories(UL), the device comprises AMT’s PostPro3D chemical vapor smoothing system and Mitsubishi’s articulated robotic arm technology.

In the materials space,Mitsubishi Heavy Industries(MHI)子公司Mitsubishi Powerhas previously signed a technology licensing agreement with french metal processing specialistAubert&Duvalfor theproduction of 3D printable metal powders。The deal marked the first step towards the full-scale inauguration of Mitsubishi Power’s additive manufacturing business.

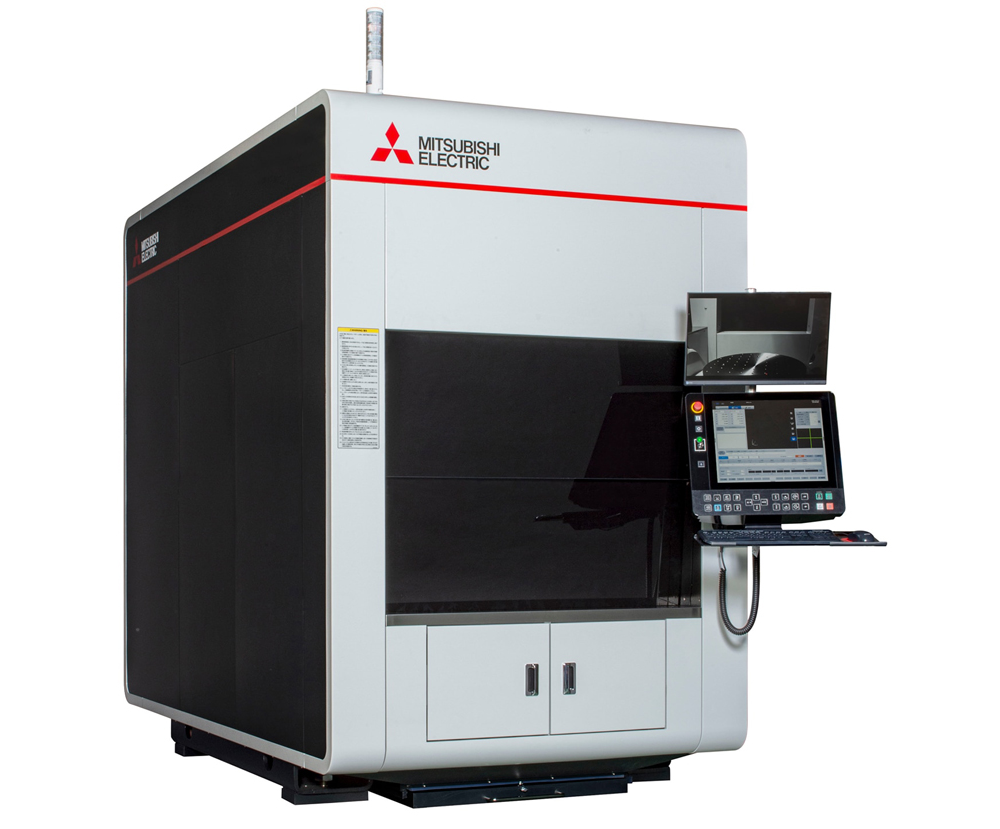

AZ600 3D打印机

基于粉末的3D打印机通常会在材料管理,可加工性和安全性方面存在问题,这已经不是什么秘密了,需要大量的专用设备和PPE。为了解决这些问题,三菱已经开发了其AZ600来处理焊接电线作为印刷材料。除了制造“清洁” 3D打印工作流程外,设计考虑因素还将使该系统更容易成为增材制造业的公司。

The AZ600 will feature a laser DED tool head, a 5-axis spatial control system, and the ability to precisely control the processing conditions of a build. According to Mitsubishi, this combination is a world-first. As well as printing new parts from scratch, the machine will allow users to print onto existing components, as is the case with many DED 3D printers.

查看两种不同的打印机型号,AZ600-F20将配备2kW振荡器,而AZ600-F40将配备4kW振荡器。该公司的销售目标是每年提供100个车型。

考虑环境影响

Mitsubishi states that the AZ600 is also set to contribute to the firm’s decarbonization goals. In recent years, there’s been a growing desire to slash CO2 emissions in the manufacturing sector (and every sector for that matter), meaning there’s a need to develop energy and material-efficient manufacturing methods. Mitsubishi expects there to be an increased demand for metal 3D printers, in particular.

In light of this, the AZ600 was reportedly designed with low energy consumption and shorter processing times in mind. The ability of the system to produce near-net shapes also allows for minimal material waste, enabling users to flexibly design large-scale metal parts with optimized weights and geometries.

三菱将展示AZ600 3D打印机Additive Manufacturing Expo from March 16-18 at Tokyo Big Sight。Further details such as the technical specifications will be unveiled then.

订阅3D打印行业newsletter有关增材制造中的最新消息。您也可以通过关注我们来保持联系推特,喜欢我们Facebook,然后调查3D打印行业YouTube频道。

寻找添加剂制造业的职业?访问3D Printing Jobsfor a selection of roles in the industry.

特色图显示了AZ600 3D打印机。通过三菱的照片。