Materialise, a global leader in 3D printing software and service solutions has announced the addition of seven technology partners in its CO-AM platform.

These solutions assist in the design and pre-printing automation, printing, post-processing, and traceability, for 3D printed parts. Additionally,Materialise Magicshas been integrated into CO-AM offering a new workflow automation feature. Bart van der Schueren, CTO of Materialise said, “With these new partnerships, the CO-AM community continues to grow, creating the first end-to-end software platform that offers an open ecosystem for the additive manufacturing (AM) industry.”

“Collaboration is key to realizing the potential of additive manufacturing and to giving our customers seamless access to a full range of software tools to plan, manage and optimize every step of their 3D printing process,” added the CTO of Materialise.

CO-AM platform partners

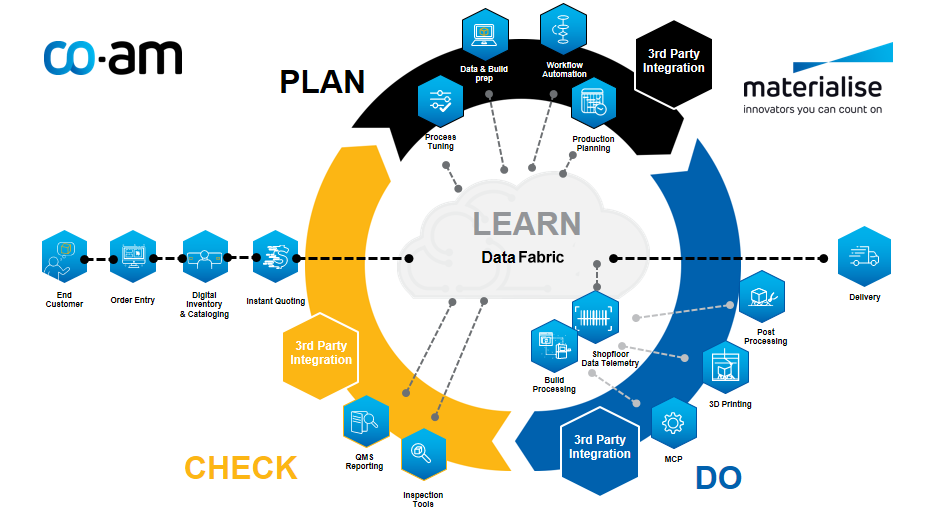

TheMaterialise CO-AM platformprovides the AM industry and manufacturing companies with room for advancements and co-development. It introduces an open software architecture that gives manufacturers immediate access to various hardware technologies in addition to their preferred tools from Materialise and other software developers. This will enable the CO-AM group to collaborate on end-to-end manufacturing solutions that will give individual companies a competitive advantage while also empowering entire industries.

Consumers in major manufacturing industries such as aerospace, automotive, consumer, medical, and energy will have access to the platform’s newest AM innovations and will be capable of seamlessly incorporating and connecting them.

特威克旨在提供包括设计自动化和自动订单创建在内的大规模定制解决方案,而Trincklewill be offering design automation for jigs and fixtures. Printer Connectivity withSLM Solutions‘ 3D printers facilitates digital traceability via automated labeling and authentication technology, whereas添加标记enables digital traceability via automated labeling and authentication technology. Solutions fromAMT,DyeMansion, andPostProcesswill be used for automating and tracking post-processing steps.

制造公司越来越多地使用增材制造来生产相同或定制的产品。但是,他们正在寻找获得重复质量标准的方法,同时最大程度地减少人类投入的量。Materizize通过增加了七个新合作伙伴来链接和优化AM流程的所有阶段的承诺。设计,标签,机器监视和后处理都与新解决方案一起自动化。

The CO-AM platform allows users to create a process that is distinctive to their company. They can select their preferred solution from a growing number of tools to support each step in the AM workflow.

Co-AM高级总监Vishal Singh说:“ Co-AM的端到端连接为我们的合作伙伴和客户提供了重要的优势。”“对于我们的合作伙伴来说,将其应用程序连接到Co-AM平台为他们提供了更有效地吸引新客户的机会。我们的客户从整个物质和合作伙伴解决方案中的统一用户体验中受益。”

CO-AM Integration and Workflow Automation with Magics 26

Magics 26, Materialise’s flagship data and build preparation software, has also been integrated into CO-AM. The incorporation improves traceability by enabling users to track and enhance AM processes from data preparation to design iterations to the final printed part.

Furthermore, Magics’ new workflow automation feature provides off-the-shelf scripts for automating common build preparation workflows as well as the ability for consumers to utilize customizable scripts to automate build preparation tasks specific to their AM operations.

“ Co-AM中MAGIC的深层集成和工作流程功能在数据和构建准备工作与整体AM工作流程之间创建了数字线程,” Magics 3D Print Suite的产品线经理Egwin Bovyn在Matertialize上。“这是启用Co-AM中所有技术的数据管理的重要步骤。它将允许用户更有效地降低生产成本和规模AM操作。”

增材制造平台

This year,PostProcess Technologies,自动化后处理系统的开发商,启用制造, a metal 3D printing service, both launched3D printing software platforms将后处理和添加剂制造提高到新的高度。后进程可用CONNECT3D platform这是其硬件,化学和软件堆栈中的新颖补充,旨在填补印刷领域的冗长空白。另一方面,启用创建了一个自定义软件包,称为EnableChainthat is intended to automate and accelerate the delivery of metal parts manufactured using its Additive Casting technology.

Furthermore,西门子的能量, an energy technology company entered a joint venture with metrology device manufacturerZEISS推出MakerVerse, a one-stop-shopon-demand 3D printing fulfillment platform. For projects that involve design prototypes and the production of spare parts on demand, the platform links industrial clients with a worldwide network of certified 3D printing suppliers.

3D印刷行业采访了Makerverse的首席执行官而且,根据Markus Seibold的说法,该平台填补了工业级添加剂制造市场的白色斑点,其部分质量非常核心。在本文中,他分享了他对未来平台的愿景,以及它将在促进工业3D打印的更大采用方面所发挥的作用。

“What sets us apart, I believe, is the fact that there is still not a fully established player in this market that can combine the advantages of a one-stop-shop digital platform with fully being able to support the needs and requirements of industrial-grade customers,” Seibold says.

Elsewhere,Dassault Systèmes,软件开发人员启动Xometry, amarketplace for on-demand manufacturing, as the first “prime partner” in Dassault’s MAKE marketplace.

MAKE marketplace, which debuted in 2018, is a system that links designers with service bureaus and machine shops. At the time, Xometry was one of several early partners. Users can access additive manufacturing, CNC milling, and injection molding.

Follow this link for all theFormnext 2022 news.

要了解最新的3D印刷新闻,请不要忘记订阅3D Printing Industry newsletteror follow us on推特,或者喜欢我们的页面Facebook.

While you’re here, why not subscribe to ourYouTubechannel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit3D Printing Jobsfor a selection of roles in the industry.

Feature image shows Materialise CO-AM platform partners. Image via Materialise.