AB-3D, a young 3D printer manufacturer based in Prosselsheim, Germany, has showcased its D-PATCH 3D printer for the first time atFormnext 2021。

该公司的首次亮相原型是在AB-3D的Fuse Loase建模(FLM)过程中运行的基于DELTA挤出的3D打印机。有趣的是,D-Patch配备了一个自动工具更换器系统,该系统使机器可以在单个打印作业中使用多达五种不同的材料进行3D打印。

Geared more towards higher performance applications, the D-PATCH is capable of processing filaments such as PETG, TPU, PA, PC, and even ceramic- and metal-infused composites. As such, the 3D printer goes beyond just multi-color prints and into the realm of multi-functional parts, with use cases in both functional prototyping and end-use production.

Multi-material delta 3D printing with AB-3D

The combination of toolchanging and delta FDM isn’t one we often see in the 3D printing industry. Delta coordinate systems differ from the common cartesian setup as the printhead moves in all three axes (XYZ) while the print bed stays completely stationary. Beyond just the aesthetics, delta printers are actually known for their faster travel and print speeds, since the weight of the single printhead is divided between the three motors.

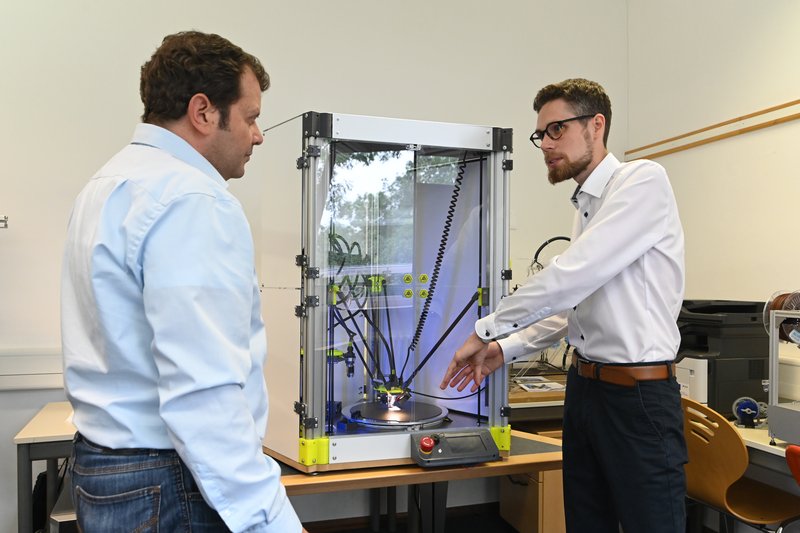

Despite the company’s infancy, AB-3D’s FLM technology has already proven itself in the academic sphere, having been used by the科堡应用科学大学for research projects.

The D-PATCH also reached the semi-finals of a local German 3D printing competition with the additive manufacturing of a multi-material industrial part.

D-Patch 3D打印机

As far as initial prototypes go, the D-PATCH actually looks like a fairly competent piece of kit. The delta machine features a cylindrical build volume of Ø300 x 400 mm, with a heated build plate and an enclosed chamber capable of maintaining temperatures of 60°C. Users will be able to choose from a selection of print surface options, including PEI coated spring steel, glass, BuildTak, and FR4/G10 glass fiber epoxy.

Although the machine only has one printhead, the integrated tool changer works to switch between five different filaments on the fly, allowing for the production of multi-material, multi-functional builds.

为了用那些高性能的细丝打印,D-Patch还提供450°C的高喷嘴温度。用户甚至可以将默认喷嘴代替另一个更适合其需求的喷嘴 - 选项列表包括黄铜,不锈钢,镀镍铜等。

Additional features include Wi-Fi connectivity, automated bed leveling, a filament runout sensor, power loss recovery, and even a particle filtration system for safe and comfortable indoor use.

Technical specifications and pricing

Below are the technical specifications for the AB-3D D-PATCH. The 3D printer is currently in the prototype phase, with a commercial launch on the horizon.

| Build volume | 300(d)x 400mm |

| Bed temperature | 最多120°C |

| Nozzle temperature | Up to 450°C |

| 室温度 | Up to 60°C |

| Print speed | Up to 200mm/s |

| Toolheads | Up to 5 |

| Nozzle diameter | 0.2 - 2mm |

Subscribe to the3D打印行业通讯有关增材制造中的最新消息。您也可以通过关注我们来保持联系Twitter,喜欢我们Facebook,然后调查3D Printing Industry YouTube Channel。

寻找添加剂制造业的职业?访问3D打印作业for a selection of roles in the industry.

Featured image shows AB-3D’s Adrian Beetz handing the D-PATCH prototype over to the Coburg University of Applied Sciences. Photo via AB-3D.