3D printer & Laser light source developer3DM Digital Manufacturing嘲笑了一项新技术,使采用者能够调整其选择性激光烧结(SLS)3D打印激光器以使用特定的材料或应用。

与二氧化碳或纤维束相比,据说3DM的可自定义激光器在减少交货时间时产生具有增强的机械性能的更高分辨率。该公司在研发设置中充分优化了其技术,现在正准备通过推出自己的专有机器将其推向市场。一旦发布,这些预计将促进自定义为关键的各种3D打印用例。

“What makes us unique is that we make our own lasers,” explains Ido Eylon, CEO of 3DM Digital manufacturing. “We don’t use CO2 or fiber lasers or anything like that, we actually produce our own lasers that allow users to aim for a certain wavelength that best matches their plastic material. That’s the difference at the core of our technology.”

SLS laser innovation at 3DM

While 3DM was nominally founded in Israel in 2016, the roots of its technology go back way further with its majority shareholder Dr. Daniel Majer. A graduate of the魏兹曼科学学院这家3DM创始人已经在电动电动部分研发方面度过了30年,同时还从事激光开发,并花了将近十年的时间在3D打印上工作。

Building on Majer’s research, 3DM has now developed a ready-for-market laser that enables the melting of polymer powders at speeds up to ten times faster than existing printing technologies. What’s more, the technology is said to be capable of turning thermoplastics into parts with a resolution much better than current leading printers, in a way that could open up new markets to industrial 3D printing.

3DM认为,3D打印可以在2019年价值5700亿美元的全球聚合物制造市场中占有更大的份额。虽然“技术创新不足”将工业3D印刷限制为“仅占该市场的百分之几”,但该公司表示,其技术的低成本和高可扩展性有可能改变这一点。

尽管3DM最初是作为一个孵化器公司Terralab Ventures它仍然拥有其股份的23%,此后一直在特拉维夫证券交易所上市。该交易使该业务的IPO在2021年6月结束了,其净资金约为1300万美元,资金为推出其首个商业产品提供了资金。

How does 3DM’s technology work?

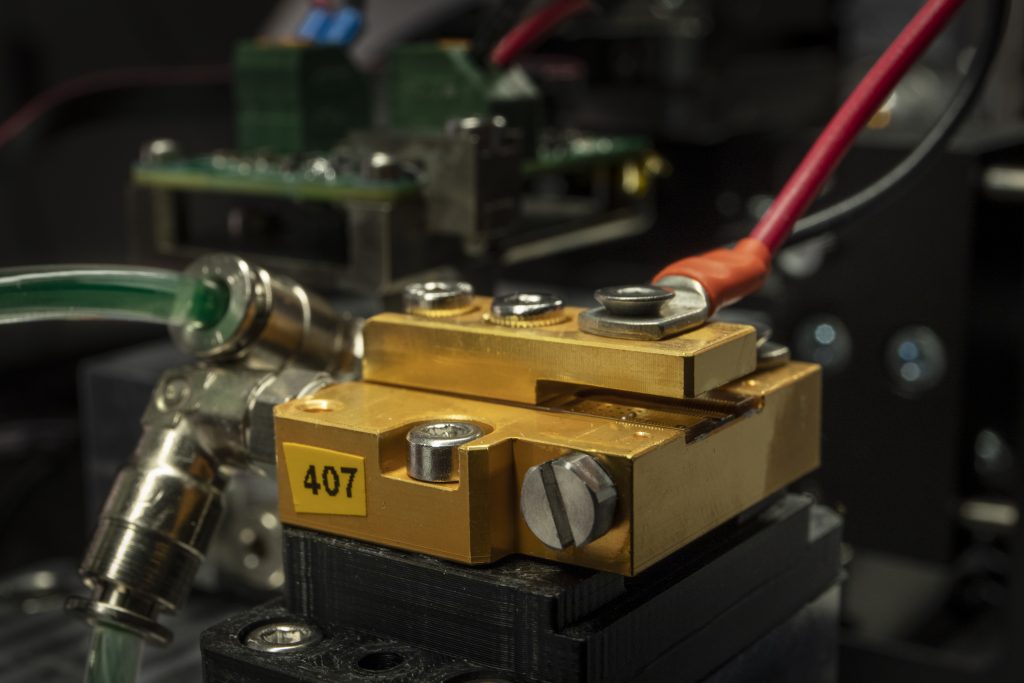

So, how exactly does 3DM’s proprietary laser differ from others on the market? Well, the light source itself is essentially formed by a set of tiny Quantum Cascade Lasers (QCL) that are smaller than a grain of rice. Each of these emits a few watts of energy, the wavelength of which can be customized to suit a given material and the way part layers are arranged.

As opposed to conventional CO2 lasers, which are fixed to a certain wavelength, 3DM says its technology allows for more efficient (and potentially much faster) laser absorption. The company also points out that its laser yields parts with a very high level of surface finish, and how its intended wavelength flexibility makes it compatible with a wider pool of materials.

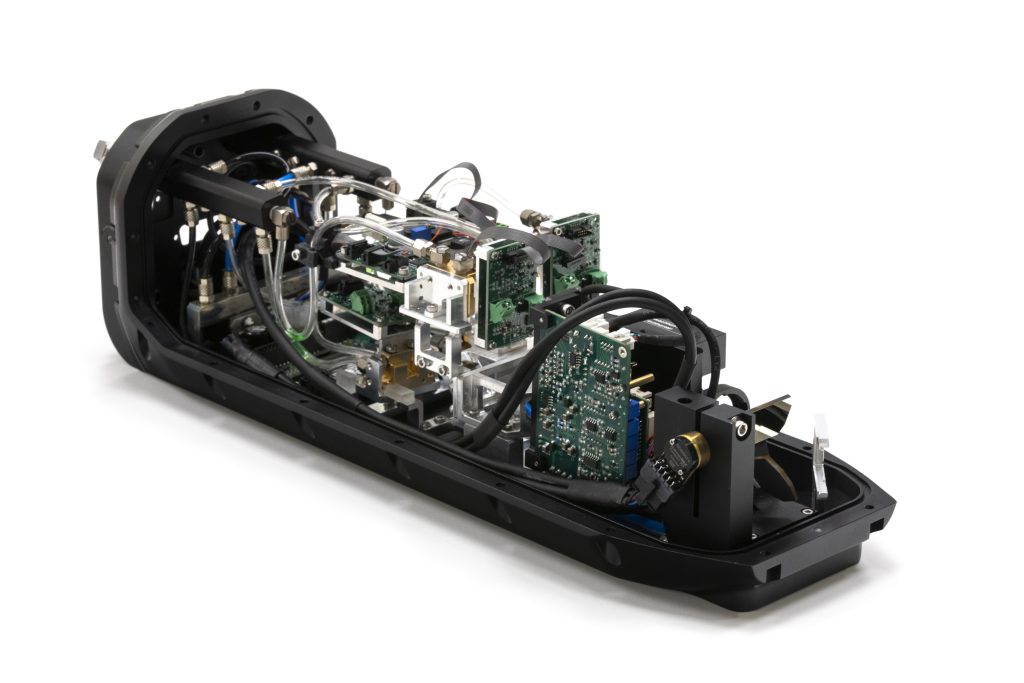

Essentially, 3DM has turned its lasers into a marketable product by affixing them to an assembly composed of a cooling mechanism, driver, and lens to form a laser module. A few of these can then be combined into a beam unit, capable of creating the first multiwavelength spot on a given powder during 3D printing, and enabling the writing of part geometries. In turn, combining four beam units to create a 3DM printhead.

With its first iteration of the product, the firm has combined four beam heads, using a stitching algorithm to ensure there are no gaps between zones. That said, the company says its approach is scalable, with the introduction of more beams likely to increase 3D printing speed. In third-party testing, the technology has even yielded parts with better mechanical properties than those of other leading SLS printers.

Elsewhere, compared to cheaper fiber lasers, 3DM’s technology is capable of hitting higher wavelengths without the need for additives to ensure laser interaction. In fact, the company’s laser can emit at any wavelength in the mid-IR spectrum, in a way that makes it capable of matching any thermoplastic’s absorption properties, and allows adopters to select the most economical feedstock for a given use case.

3DM即将推出的市场

Already, 3DM has integrated its laser printheads into four-head prototype R&D systems, and its first-generation machine is now said to be closing in on ‘productization.’ Though the exact specifications of these machines haven’t been public, they’re understood to have printheads mounted to the roof of their build chambers, in a layout that makes cooling more efficient.

3 dm技术上面继续迭代,我t aims to identify its potential sustainability and ease-of-post-processing benefits. Application-wise, the company has verified its ability to produce parts from flexible materials like insoles, but it continues to see wide-ranging use cases for its lasers, particularly in areas where mass customization and specialty materials are needed.

With beta machines set to be shipped by mid-2023, and a full launch earmarked for late 2023, the firm continues to engage with technology and applications partners to broaden its capabilities and offerings.

鼓励那些从事有兴趣协作激光福利和应用程序开发的材料或流程的人在此处联系3DM数字制造to find out more.

要了解最新的3D印刷新闻,请不要忘记订阅3D打印行业通讯or follow us onTwitteror liking our page onFacebook。

While you’re here, why not subscribe to ourYouTubechannel? featuring discussion, debriefs, video shorts and webinar replays.

您是否正在寻找添加剂制造业的工作?访问3D Printing Jobsfor a selection of roles in the industry.

Featured image shows 3DM Digital Manufacturing’s laser printhead. Image via 3DM Digital Manufacturing.