UK-based engineering firmWayland Additivehas announced the development of its new electron beam powder bed fusion technology – NeuBeam. After licensing the process from parent companyReliance Precision, Wayland hopes to commercialize it and fulfil six deliveries of the system by the end of the year.

Charge neutral 3D printing

根据理查森,韦兰的首席执行官添加剂ive, NeuBeam is capable of neutralizing the charge accumulation that tends to occur with other electron beam technologies such as electron beam melting (EBM). This results in a wider range of viable print parameters and increased material flexibility with NeuBeam, when compared to other electron beam or laser-based PBF technologies.

被作为“热过程一部分”首席执行官同僚ed to a “hot bed process”, the NeuBeam system will see heat being applied to only the relevant sections of the build area, where the part is being printed. This has the effect of avoiding partially sintered powder, which can fuse to the part, deteriorating its surface finish. Unused free flowing powder is left in the bed, and any powder in or on the part can be removed with minimal post-processing.

The NeuBeam also boasts reduced power consumption and, reportedly, residual stress-free 3D printed parts. The issue of residual stress has been around for as long as PBF, and can be destructive in extreme cases. The rapid cyclic heating and cooling caused by the hatching, or scanning, of the beam results in layer contraction. The various layers pull on each other and form shear stresses within the part. The effect is most severe in parts with large cross-sections, as these tend to have longer weld-tracks so there is a greater distance for the shear stresses to act over. If the NeuBeam really can fabricate stress-free parts, it could potentially enable large part production on a scale currently unseen in PBF.

Real-time in-situ monitoring

Wayland’s NeuBeam system also features real-time in-situ part monitoring via structured light scanning, electron imaging, and high speed infra-red camera modules. This gives users the option to change process parameters mid-print to optimize the part’s microstructure as it is being formed or to completely cancel a print if it is beyond repair. Wayland also expects the tracking and fine-tuning enabled by the monitoring system to aid researchers in material development.

With its NeuBeam system, Wayland is looking to shake up the electron beam PBF market. Using£3M in funding, an investment led by Longwall Ventures and the Angel CoFund, the Yorkshire-based company hopes its multitude of features will be enough to topple some of the more established EB system manufacturers. Just last year,Ruselectronics, a Russian holding corporation and subsidiary of state-ownedRostec, announced the development of its ownEBM 3D printer for aerospace applications.

The nominations for the2020 3D Printing Industry Awardsare now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the3D Printing Industry newsletterfor the latest news in additive manufacturing. You can also stay connected by following us onTwitterand liking us onFacebook.

Looking for a career in additive manufacturing? Visit3D Printing Jobsfor a selection of roles in the industry.

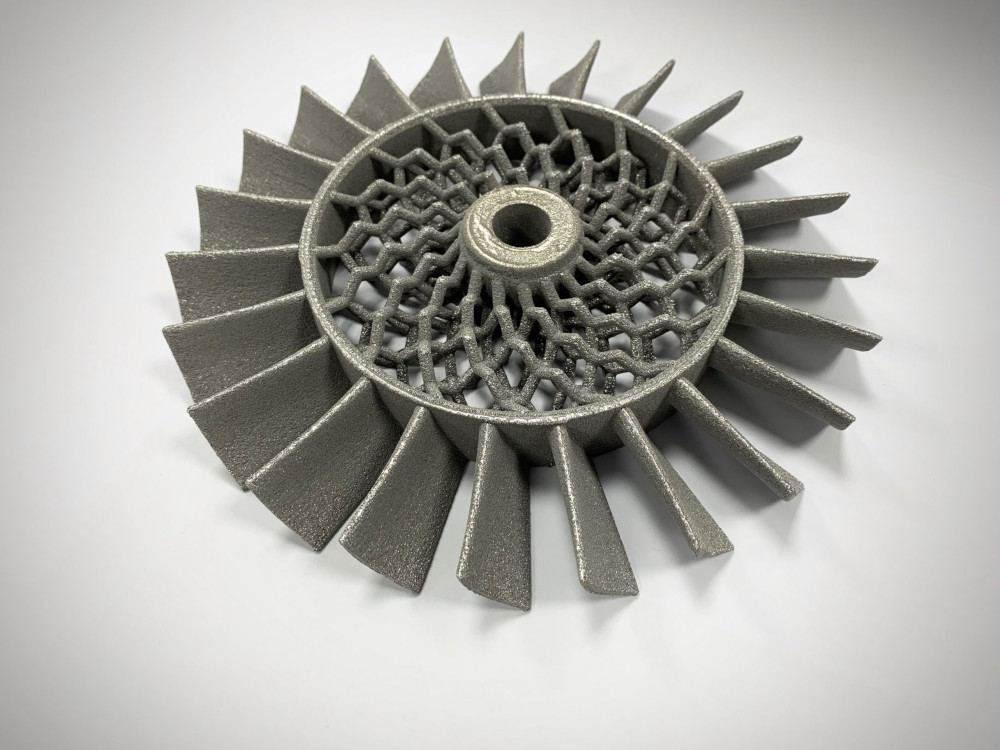

Featured image shows the NeuBeam system 3D printing an industrial part. Photo via Wayland Additive.