The nominations for the2021 3D Printing Industry Awardsare now open. Who do you think should make the shortlists for this year’s show? Tell us now before this week’s deadline.

The UK’sDigital Manufacturing Centre(DMC) is now an approved supplier of 3D printed parts made of Scalmalloy.

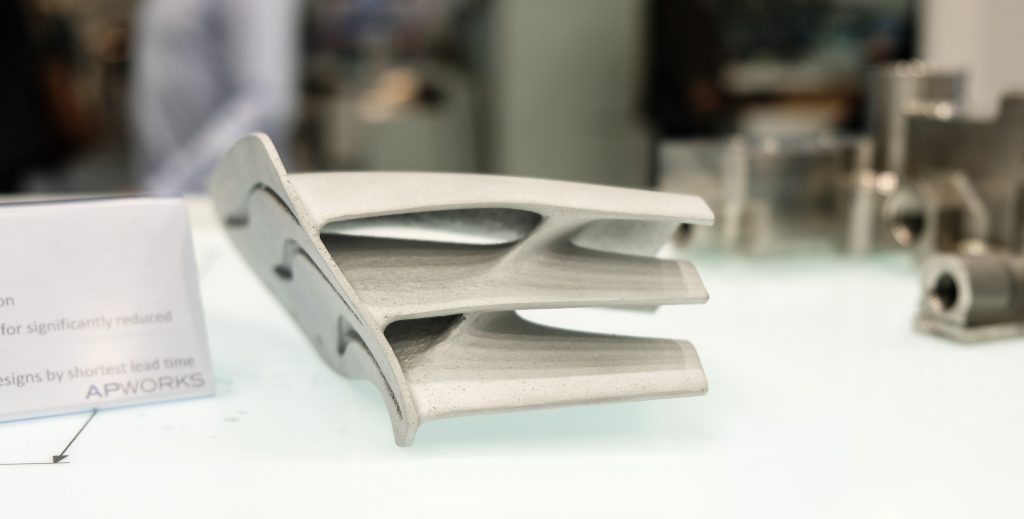

Developed by aerospace 3D printing firmAPWORKS据报道,高性能材料highest strength aluminum alloy available for additive manufacturing.

As part of the supplier certification, the DMC 3D printed a set of Scalmalloy components which were then inspected by APWORKS. The part qualities achieved have placed the DMC in the top 1% of Scalmalloy part suppliers worldwide.

Kieron年代alter, CEO of the DMC, stated, “The DMC team is focussed on solving customer challenges, whether that means engineering for application, producing high-quality components at short notice, or bringing new high-performance AM materials to the UK market. British companies working at the frontier of their industry now have a highly qualified and knowledgeable approved supplier to help them take advantage of this revolutionary material and process.”

高强度的鳞片

Blending aluminum, magnesium, and scandium, Scalmalloy was originally developed by APWORKS and its parent company空中客车for aerospace components, but has since found its place in other high-performance applications such as motorsports. Last year, the material was evenadded to the Formula 1 regulationsas an approved AM material by the国际足联(Fédération Internationale de l’Automobile).

As the highest strength aluminum alloy compatible with 3D printing, it offers properties comparable to those of 7000 series alloys. Despite its relatively low density of 2.67 g/cm³, Scalmalloy features a tensile strength of 520MPa and a yield strength of 480MPa. The material also has excellent ductility, qualifying it for use in highly loaded and safety-critical components.

此外,合金自然抗腐蚀,并在热老化时表现出高度的微观结构稳定性。合金的元件通常不利于其耐腐蚀性,但是ScalMalloy使用了一种特殊的强化机制,使其具有与5000系列铝合金等同的耐腐蚀性。

Bringing Scalmalloy to the UK

With the DMC now offering Scalmalloy parts, the UK’s heavy industrial sectors are in a position to leverage a combination of high-performance material properties and the design freedom offered by 3D printing technology. Certified as a top 1% supplier of the material, the DMC will also be able to offer its customers expertise in part optimization, enabling maximum performance for minimum weight.

The applications of APWORKS’ material stretch far and wide, encapsulating use-cases in space-ready parts, racing yacht decks, and Formula 1 drivetrains.

“Scalmalloy is a fantastic addition to our capabilities – particularly for our space, aerospace, and motorsport customers,” said Salter. “Not only is it relatively straightforward to process, but it also offers many incredible performance benefits. Perhaps most importantly, it has a proven track record with established use in some of the most demanding applications in the world.”

Innovative 3D printing materials like Scalmalloy are a major factor in the advancement of additive manufacturing and its applications. Scientists from theEindhoven University of Technology(TUE) recently developed a novelcolor-changing liquid crystal inkthat is compatible with 3D printing technology. Until now, it’s been extremely difficult to print such materials into complex structures and devices, so the team believes its work could have major implications for applications such as decorative lighting, soft wearable sensors for health monitoring, and even augmented reality optics.

Elsewhere, Chinese 3D printer manufacturerFarsoon Technologiesrecently strengthened its partnership with French materials producer极好用于开发3D可打印材料食物接触和饮用水应用。这两家公司正在寻求帮助最终用户使用特定于工业应用的新材料,即食品接触行业的蓝色,并且主要适合自来水部门。

Subscribe to the3D Printing Industry newsletterfor the latest news in additive manufacturing. You can also stay connected by following us onTwitter, liking us onFacebook, and tuning into the3D Printing Industry YouTube Channel。

Looking for a career in additive manufacturing? Visit3D Printing Jobs选择的角色。

Featured image shows the DMC team 3D printing Scalmalloy on a Renishaw system. Photo via DMC.