加州大学伯克利分校(加州大学伯克利分校)研究人员开发了一种冷冻调节的交联方法,可以允许对人体组织的3D生物打印具有改善的临床活力。

与基本生物的组织不同,该组织可能太软以至于无法支撑自己的体重,该团队的技术会看到生物墨水冷冻和交联,从而促进了能够保留所需形状的细胞结构的创建。利用这种“ 3D认测”过程,科学家认为,有可能产生用细胞播种的坚固藻酸盐支架,以进行实验室培养或组织再生。

重新考虑“ 3D压印”过程

Although 3D bioprinting has become a popular means of engaging in cell-based research, the technology remains difficult to use with softer biomaterials like sodium alginate. Despite the seaweed-based complex carbohydrate’s relative affordability and strong biocompatibility, it continues to come with lengthy lead times caused by necessary cross-linking.

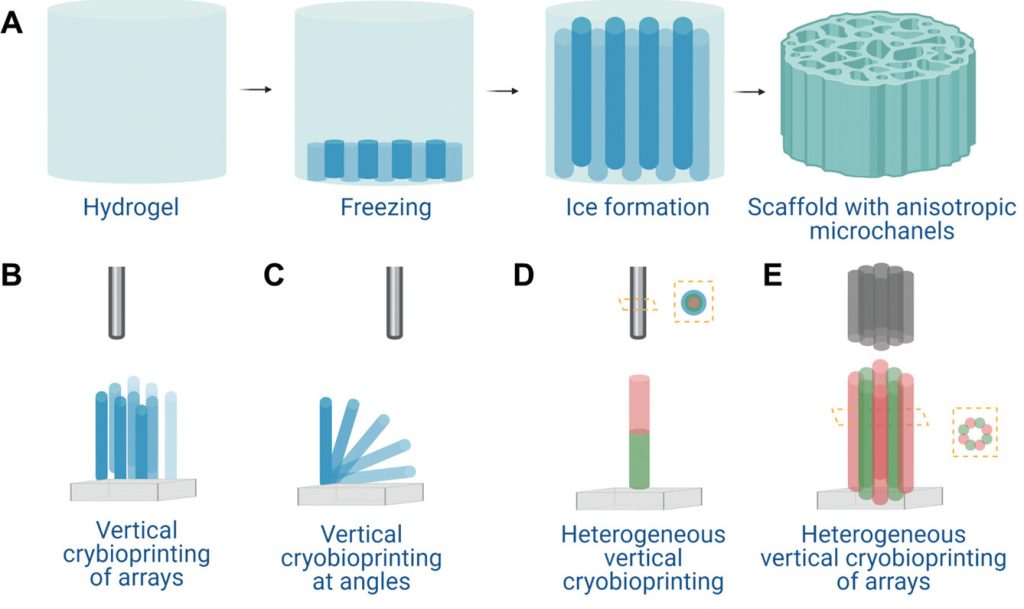

In order to get around the drawbacks of such bio-inks, many researchers now print them into structures layer-by-layer using 3D cryoprinting, a process that sees them rapidly cooled and frozen into place upon deposition. However, as the Californian team point out in their paper, the technology’s approach to solidifying materials also makes them difficult to cross-link, and thawing can lead to their collapse.

To make matters worse, the scientists add that 3D cryoprinting often necessitates the use of internal crosslinking, which only allows bio-inks to be extruded for short periods before they suffer from high viscosity, and the process of defrosting also reduces scaffold viability, particularly in tissue engineering applications.

磨练冰冻调制的替代方案

In their efforts to come up with an alternative to conventional 3D cryoprinting, the scientists have developed freezing-modulated cross-linking, a process in which structures are frozen but then thawed in a calcium bath. Through doing so at a controlled rate, the team says it’s possible to cross-link tissues layer-by-layer, thus allowing them to retain a set shape.

During the early stages of their technology’s R&D, the researchers began by using a mathematical model to identify the optimal temperature at which materials should be frozen and defrosted. Once these parameters had been established, the team harnessed their process to produce a variety of multi-layer alginate objects, which could be refrigerated or kept frozen for later cell-based experimentation.

最初的结果表明,材料被沐浴的钙数量,对其收缩没有影响,并且没有发现该过程的温度也不会产生任何准确的好处。也就是说,当涉及到脚手架的解冻时,以较高的速度熔化确实会导致它们收缩,而在20°C下的组织交联比在-0.05°C下的交联小。

研究人员说,在鉴定出-80°C的对象温度和-0.05°C的浴温温度为过程的理想参数之后,研究人员说,它现在可以扩大3D Cryoprinting的应用。但是,该团队还接受进一步的研究需要进一步研究其方法影响细胞活力的方式,这对于其在再生组织研发中的部署至关重要。

冻结3D生物打印开发

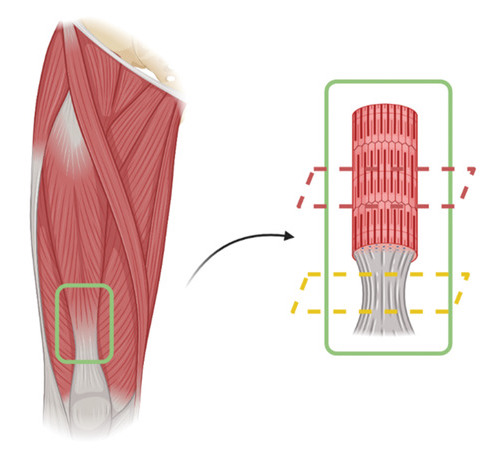

与传统的3D生物打印一样,密码构成仍然是基于实验室的研究的主题,世界各地的科学家都在寻求完善和实验这项技术。今年早些时候,一个团队在Harvard Medical SchoolandSichuan Universitydeveloped a novel means of3D printing freestanding, mixed-cell tissues, including live human muscle-tendons.

早在2018年,研究人员Imperial College London, also developed a similar method, which involvedusing cryogenics to 3D print soft tissues, capable of fooling the human lungs and brain into thinking they’re genuine. At the time, the seeding of live dermal fibroblast cells onto 3D printed scaffolds was seen as an important step forward that showcased the potential of cryoprinted inks.

Elsewhere, other 3D bioprinting developments have seen the technology advanced to the point that it can be used to produce highly-complex cell structures. Late last year, for instance, scientists at theUniversity of Montréal,Concordia Universityand theFederal University of Santa Catarina,能够3D Bioprint小鼠脑细胞.

The researchers’ findings are detailed in their paper titled “冻结调节 - 跨链接:3D压印的交联方法,” which was co-authored by Linnea Warburton and Boris Rubinsky.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the3D打印行业newsletter或跟随我们推特或喜欢我们的页面Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to ourYoutubechannel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit3D打印作业在行业中选择一系列角色。

Featured image shows UC Berkeley’s Etcheverry Hall facility, which houses its mechanical engineering department. Photo via UC Berkeley.