来自加利福尼亚大学戴维斯(UC Davis) have published a paper detailing a new approach to 3D printing using microfluidics, led by chemical engineering assistant professor Jiandi Wan.

新技术使用droplet-based multi-phase microfluidic system to efficiently 3D print finely-tuned flexible materials. It allows the user to manipulate the extruded ink composition and properties in real time, enabling the fabrication of diverse and functional structures with varied compositions and properties. The researchers see potential applications for the technology in soft robotics, tissue engineering and wearable technology.

Droplet-based 3D printing using microfluidics

研究人员首先解释说,尽管3D打印技术可能旨在“在印刷结构中无缝改变组成和功能性能。但是,大多数用于挤出印刷的油墨在构图上是静态的,用于墨水组合物的动态调整的可用方法仍然很少。”

Indeed, with traditional extrusion-based 3D printing technology, material is pushed through a nozzle and added to the structure repeatedly, layer-by-layer, until the product is complete. Although an efficient and cost-effective process, it makes it hard to print structures made of more than one material and getting the right amount of softness can be a challenging process.

As such, Wan’s group sought to create an approach for extrusion-based 3D printing that allowed the modulation of extruded inks at the point of print, using droplet inclusions. The researchers noticed that the nozzle used in extrusion-based 3D printers is similar to the glass capillary microfluidic devices that the team had been studying. These devices use multiple nozzles place within each other, realized it could be adapted for 3D printing, to be used as the printhead: “Most extrusion-based 3D printers use very simple nozzles and since we had already developed these glass microfluidics, we thought, ‘why not apply it to 3D printing?’” explains Wan.

Wan’s team developed a device that uses a multi-phase drip system to encapsulate droplets of an aqueous polyethylene glycol diacrylate (PEGDA) solution inside of a common silicon-based organic polymer called polydimethylsiloxane (PDMS). The PDMS flows around a dripper, creating tiny droplets of the PEGDA which are then evenly inserted into the PDMS as both materials flow onto the 3D printed structure as it is fabricated.

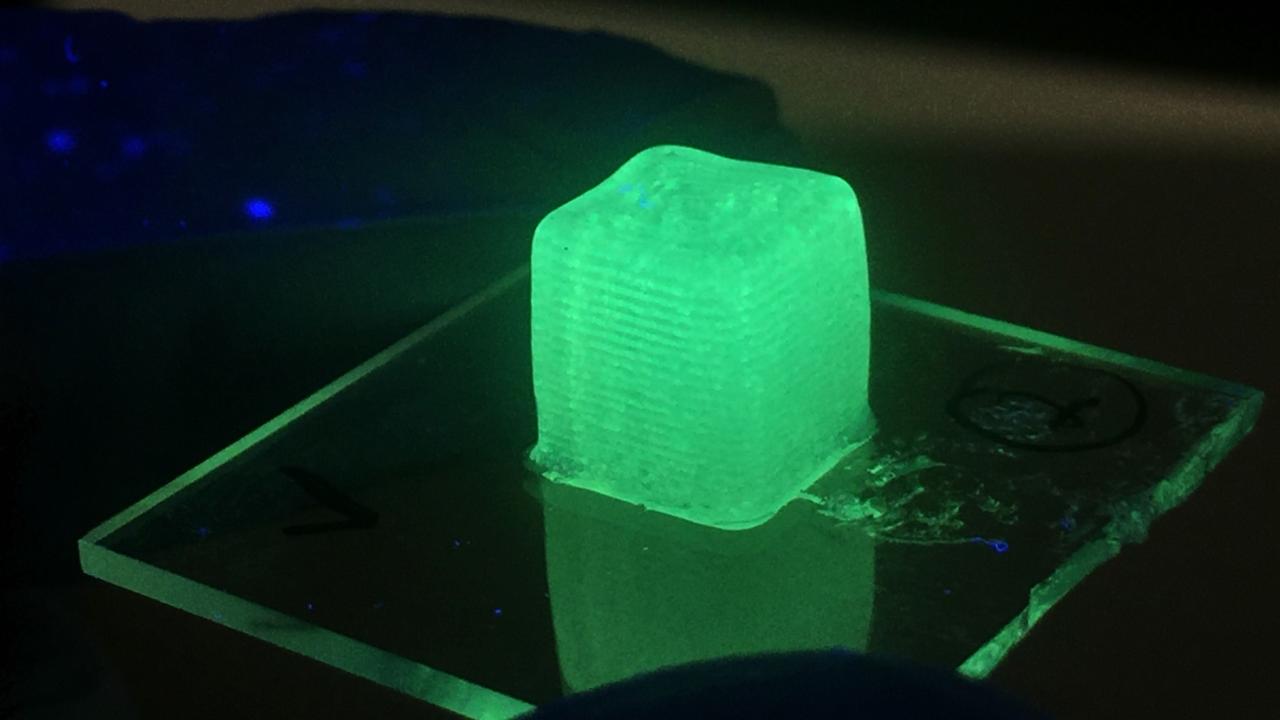

The final structure is described as looking like a “Pac-Man maze” with tiny dots of PEGDA droplets surrounded by PDMS. After the PEGDA diffuses out of the droplets, it interferes with the polymerization process of PDMS, causing the material to soften and making the structure more flexible.

湾的研究小组也证明了滴plet-based 3D printing method can be used to produce flexible porous constructs with encapsulated polymer particles and metal droplets. Furthermore, the structure flexibility can be modified by altering the droplet size and flow rate. This provides researchers with a wide range of choices to design their material structure and vary flexibility to the intended application, in a way that’s difficult with standard nozzle-based methods.

本文中的作者解释说:“可以通过改变液滴的空间分布,包括水和液态金属液滴的空间分布来原位调节3D打印构建体的机械特性。”

Microfluidics in 3D printing

微流体通常是指具有数十微米尺寸的通道中流体操纵技术。基于微流体学的3D打印不是一个新概念,利用该技术的各种系统和流程。确实,2019年,欧洲研究人员对3D打印微流体应用, which they state will “Ultimately allow the creation of a new generation of increasingly smart, responsive, and autonomous devices, able to sense and act upon their environment in complex ways and with reduced human intervention.”

For example, theSingapore University of Technology and Design‘s(SUTD)软流体实验室开发了一种简单的方法3D print microfluidic devices2019年8月与流体处理和功能组件集成。

Furthermore, in March 2018, researchers fromNew York Genome Center(NYGC) andNew York University(NYU) created an open-source, bedside3D打印的液滴微流体控制仪器. The device represents a cheap, accessible method for identifying and targeting the correct cells to treat diseases like Rheumatoid Arthritis (RA).

本文讨论的研究:On-demand modulation of 3D-printed elastomers using programmable droplet inclusions,” is published in theProceedings of the National Academy of Sciences of the United States(PNA)。

提名2020 3D Printing Industry Awardsare now open. Who do you think should make the shortlists for this year’s show? Have your say now.

订阅3D打印行业newsletter有关增材制造中的最新消息。您也可以通过关注我们来保持联系推特and liking us onFacebook.

寻找添加剂制造业的职业?访问3D Printing Jobsfor a selection of roles in the industry.

特色图片显示材料用WAN实验室的新液滴基于3D打印方法打印。通过Jiandi Wan的照片。