Belgian software and 3D printing service providerMaterialise(MTLS) has reported record-breaking revenue figures during Q3 2021.

The company’s financials show that over the quarter, it brought in €52 million, which doesn’t just represent 28% more than the €41 million it reported in Q3 2020, but the highest figure it has ever achieved in Q3. Despite seeing a dip in automotive and aerospace demand, Materialise says it has been able to drive sales by applying its 3D printing offering selectively, and due to a wider market recovery.

Over the course of Q3 2021, the firm’s best-ever third quarter also saw it report a net profit of €9 million or €0.15 per diluted share, and this has been received positively by shareholders, who have sent its shares soaring 14% since the results came out.

“Our manufacturing segment had been suffering much longer from COVID,” Fried Vancraen, CEO of Materialise told analysts and investors on the firm’s earnings call. “Today, we see that as the market rebounds, we are also able to generate healthy numbers in the manufacturing segment. This is largely due to the transition of our manufacturing segments toward more and more certified manufacturing projects.”

实现2021年第三季度成果lts

Materialise reports its revenue across three divisions: Software, Medical, and Manufacturing, and while each segment recovered significantly compared to last year, its production arm was the star of the show during Q3 2021. The division, which includes revenue gained from the firm’s 3D printing, as well as its vacuum and investment casting offerings, raised €23 million or 61% more than it did in Q3 2020.

According to Vancraen, the segment was able to continue arecovery it started in Q2 2021,由于出现的策略寻找“meaningful applications,” and “certified manufacturing projects.” In doing so, he told analysts that the company has been able to drive growth in its wearables and medical businesses, and mitigate against a decline in its automotive prototyping and aviation demand.

The company’s Medical division also grew by 10% between Q3 2020 and Q3 2021, bringing in €19 million, and it was the only area of the business that out-stripped its pre-pandemic revenue levels. While Materialise’s healthcare devices and services revenue rose by 8.5% compared to last year, its Medical performance was bolstered by a 31% increase in related software sales and efficiency gains as well.

Lastly, the firm’s Software business generated €10 million in Q3 2021, a 10% improvement on the €9 million reported in Q3 2020, but a 9% decline on the €11 million it brought in during Q3 2019. This dip was somewhat down to a €0.5 million rise in its deferred revenue from license and maintenance fees, and Materialise maintains that the division’s cross-segment sales now account for 31% of its total.

| 实现收入(€) | Q3 2020 | Q3 2021 | Difference (%) | Q3 2019 | Q3 2021 | Difference (%) |

| Software | 9m | 10m | +10 | 11m | 10m | -9 |

| Medical | 17m | 19m | +10 | 15m | 19m | +27 |

| Manufacturing | 14m | 23m | +61 | 24m | 23m | -4 |

| Total Revenue | 41m | 52m | +28 | 50m | 52m | +4 |

Focusing on “meaningful applications”

Over the third quarter, there were plenty of signs of Materialise’s manufacturing recovery on show, with the firm’s 3D printing offering finding new applications within the aviation and bicycle industries. In one such use case, the company was contracted to3D print 2,000 bike partsforPinarello’s‘Dogma F,’ while in another, it worked withEOSto createSLS-printed flight-ready componentsforAirbus.

On the firm’s conference call, Vancraen also revealed that its services have been adopted as part of a similarly aviation-focusedLift Aircraftproject. Throughout the R&D of the company’s ‘Hexa’ drone-like electric taxi, Materialise has helped design and print 89 end-use parts for the craft, which are said to have reduced its build time by eliminating the need for support structures.

Moving forwards, Vancraen added that the company will continue to target “meaningful applications” in which it “can get under the skin” of clients’ workflows to deliver tangible results, thus he stressed that growth wouldn’t necessarily require scaling its capacity.

“It’s not the aim of Materialise to over-invest in capacity, because we have always seen that we need to focus our manufacturing to the high-end applications of 3D printing,” Vancraen explained on the earnings call. “Rather than filling [our order book] with volume, we prefer to go for those applications where we believe that serious value can be made. So there is no plan to expand capacity in a big way.”

Instead, the company says that it intends to “gradually add extra machines” to its portfolio, while building up its activities at the new plant it opened in Bremen earlier this year. The firm also attributes much of its Q3 success to the upgrades it has made toMagicsandMimics, as well as its MES, CMS and wearable initiatives, thus it intends to continue its level of R&D spending, which rose 13% during the quarter.

Materialise’s “comfortable” projections

Vancraen closed Materialise’s earnings call by reiterating that he expects the firm’s automotive demand to remain low for the rest of the year, but he remains “comfortable” setting guidance for FY 2021 of €197-200 million. Due to the number of deals the company has in the pipeline, he said that it has a “good grip” on its projected earnings, thus he says results will be “in the higher end” of its range.

Materialise is also in a strong cash position heading into Q4 2021, with €194 million in liquid capital, thanks in part to thefour million-share public offeringit made in June, which brought in €11.4 million more than expected, afterJP Morgan Securitieschose to take up its option as underwriters of the deal to buy 600,000 extra shares.

Looking ahead, Vancraen added that the company is targeting further green applications of its technologies, after successfully helping Lift Aircraft with its electric ‘eVTOL’ project, in keeping with its own plans to halve its carbon footprint by 2025.

“The eVTOL is a new breed of vehicles that is expected to be a growing market and open a new mode of mobility,” concluded Vancraen. “The unique benefits of additive manufacturing are really crucial to building reliable systems that are so light, they can take up passengers only with electric energy, and that is the kind of market which we really fundamentally believe in.”

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the3D Printing Industry newsletteror follow us onTwitteror liking our page onFacebook.

For a deeper dive into additive manufacturing, you can now subscribe to ourYoutubechannel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit3D Printing Jobsfor a selection of roles in the industry.

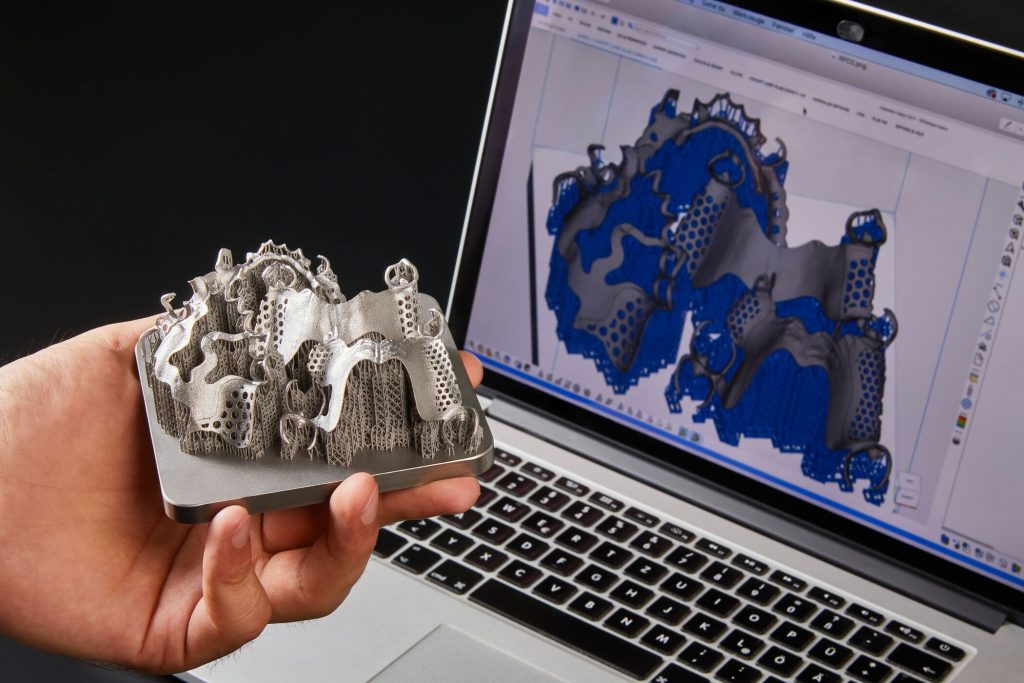

Featured image shows Materialise’s recently new Metal Competence Center in Bremen, Germany. Photo via Materialise.